Method for testing forming limit of tailor welded blank during metal plate incremental forming

A technology of incremental forming and sheet metal, applied in the field of sheet metal forming, can solve problems such as weld cracking, and achieve the effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] A forming limit test method of tailor-welded blanks in incremental forming of sheet metal mainly includes two parts: test and data reading.

[0029] Specifically include the following steps:

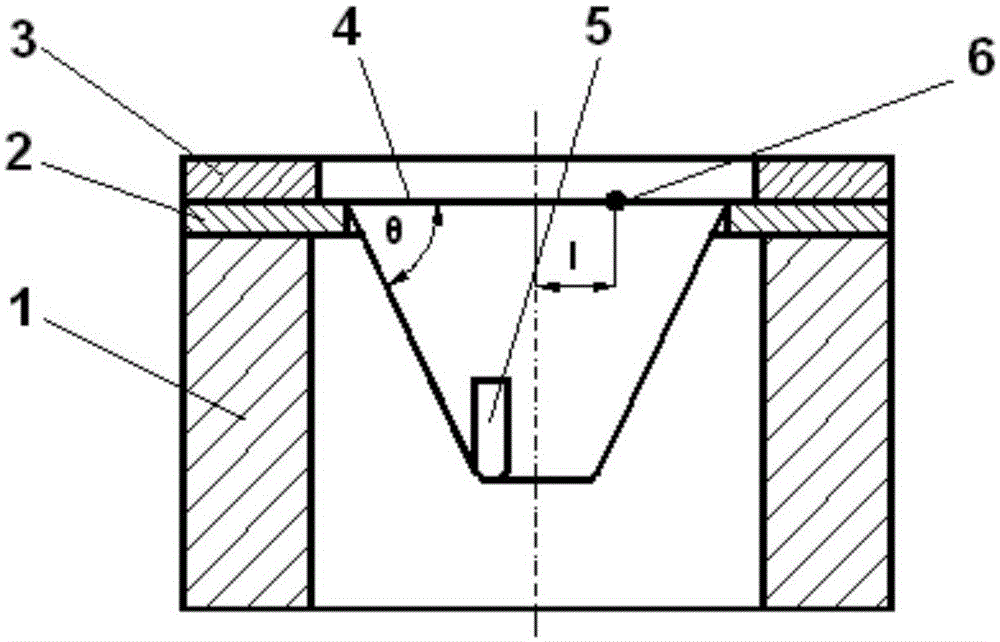

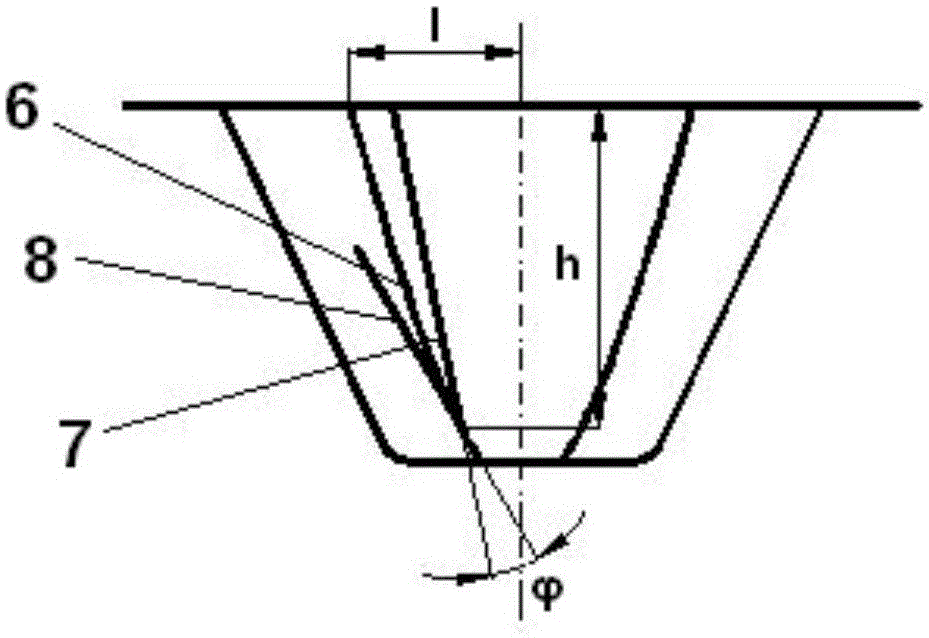

[0030] Step 1: Construct the geometric model required for forming in the 3D modeling software, such as conical parts with different forming angles θ;

[0031] Step 2: If figure 1 , 2 As shown, the fixture base 1 is installed on the workbench of the progressive forming machine tool, and then the supporting plate 2 and the pressing plate 3 are placed in sequence, and a line is drawn on the supporting plate 2 to determine the offset l of the weld 6. 3. Place the sheet material 4 in the middle. When placing it, the weld seam 6 needs to be aligned with the marking line on the support plate 2. Fix the supporting plate 2 and the pressing plate 3 on the fixture base 1 with fas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com