Fluid centrifugal control system

A control system and fluid technology, applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve problems such as increased energy consumption, complex reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

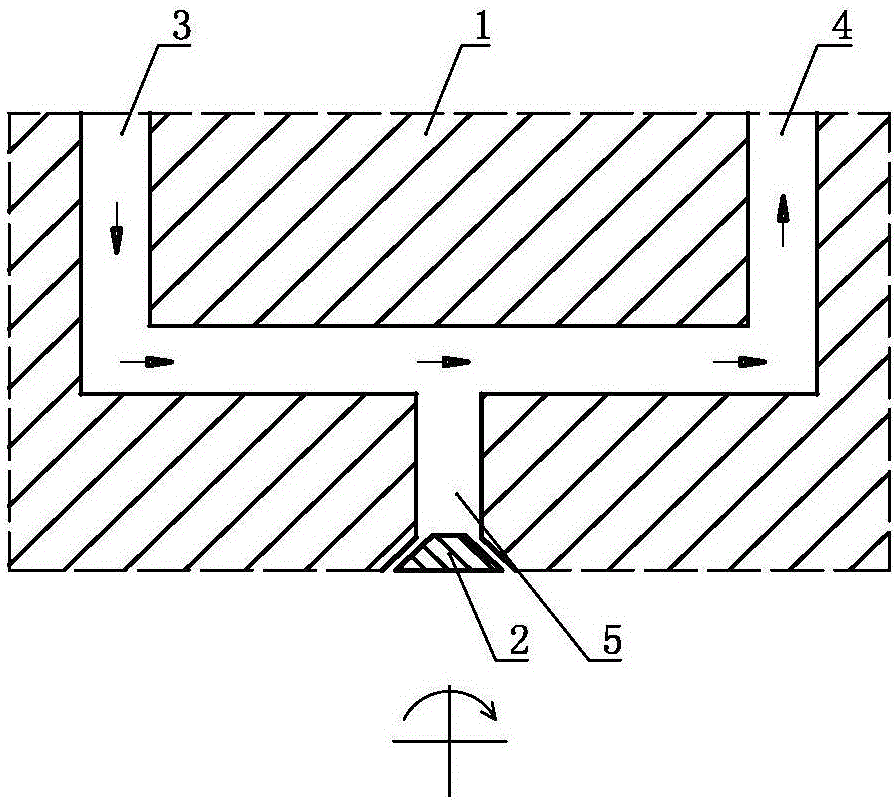

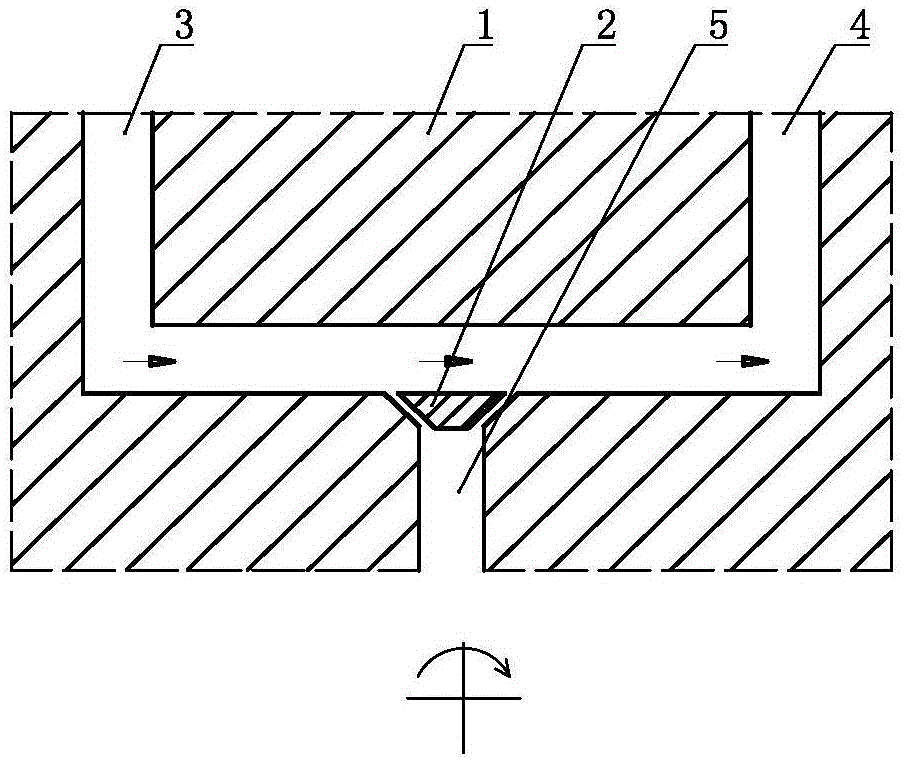

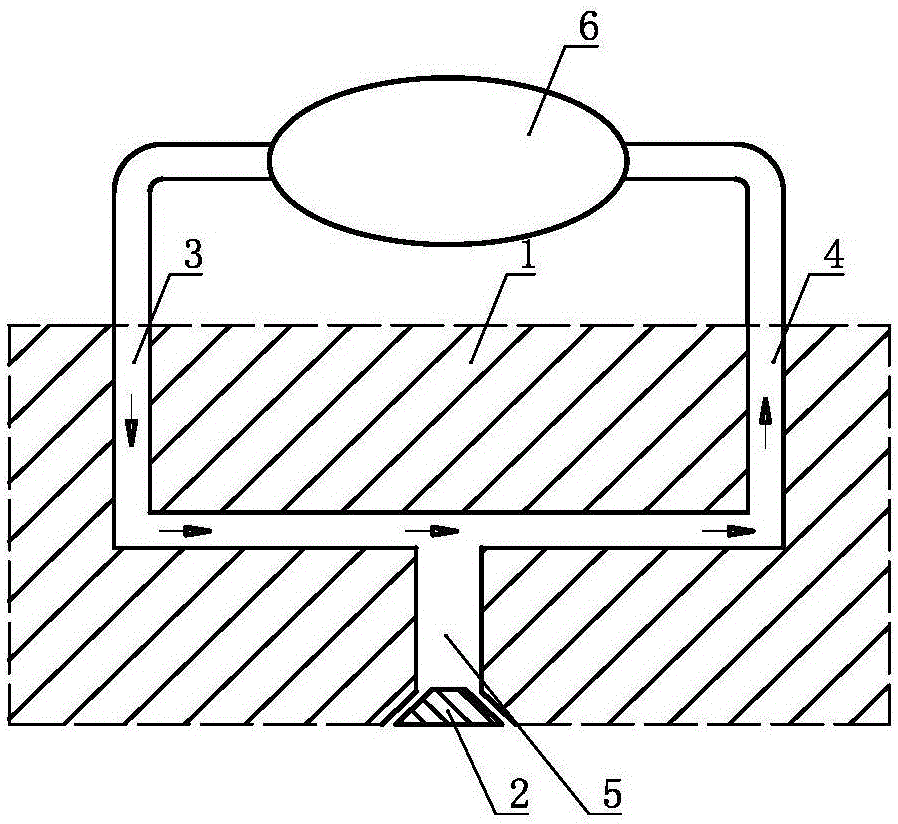

[0053] A fluid centrifugal control system, comprising a three-way fluid channel body 1 and a structure body 2, the three-way fluid channel body 1 includes an inflow channel 3, an outflow channel 4 and a discharge channel 5, the structure body 2 and the discharge channel The flow channels 5 are arranged correspondingly. The structure 2 is subjected to the joint action of the rotating centrifugal force and the fluid pressure in the inflow channel 3. The direction and effect of the fluid pressure in the inflow channel 3 acting on the structure 2 The angle between the acting directions of the rotating centrifugal force on the same structure 2 is greater than 90 degrees, and the displacement of the structure 2 controls the flow state of the discharge channel 5 .

Embodiment 2

[0055] A fluid centrifugal control system, such as figure 1 As shown, on the basis of Embodiment 1, the effect of the rotating centrifugal force further makes the structure 2 tend to close the discharge channel 5 .

Embodiment 3

[0057] A fluid centrifugal control system, such as figure 2 As shown, on the basis of Embodiment 1, the effect of the rotating centrifugal force further makes the structure 2 tend to open the discharge channel 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com