Film system designing method for optical thin film on optical lens with high caliber-curvature-radius ratio

A curvature radius, optical thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of large diameter curvature radius ratio lens optical thin film film system design difficulty, poor optical thin film thickness uniformity, The problem of wide distribution of light incident angles, etc., to achieve the effect of easy implementation, simple implementation, and improved spectral performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

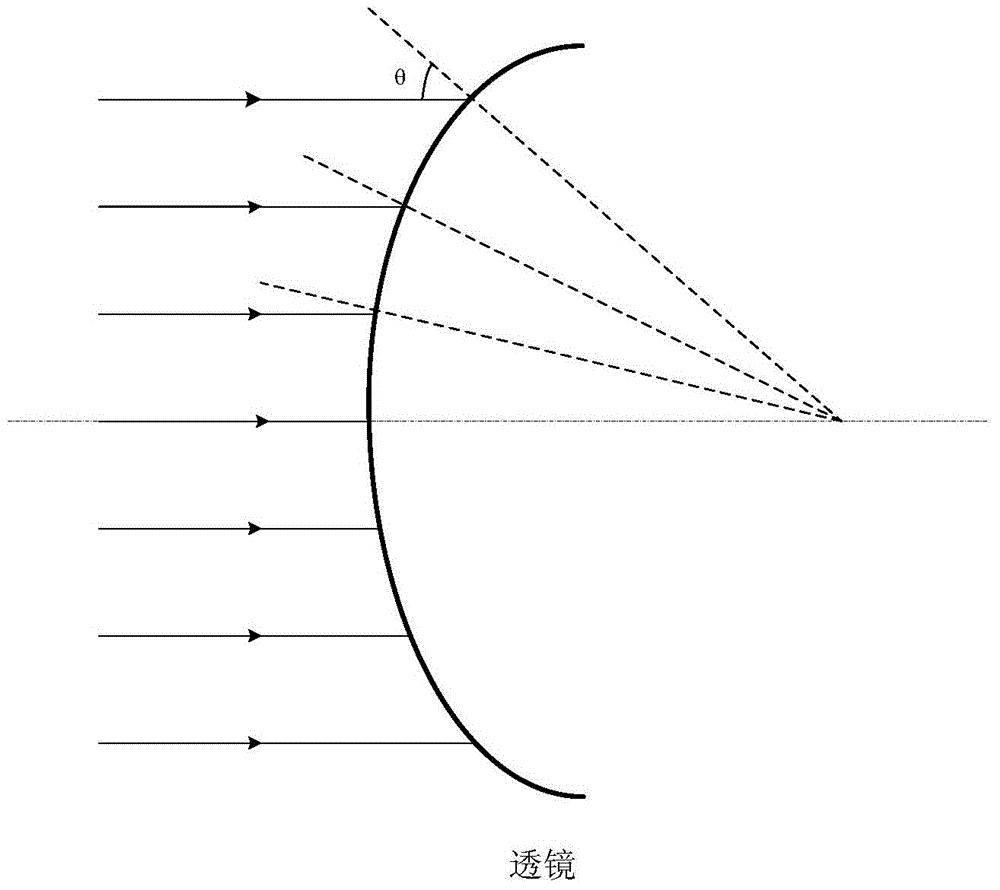

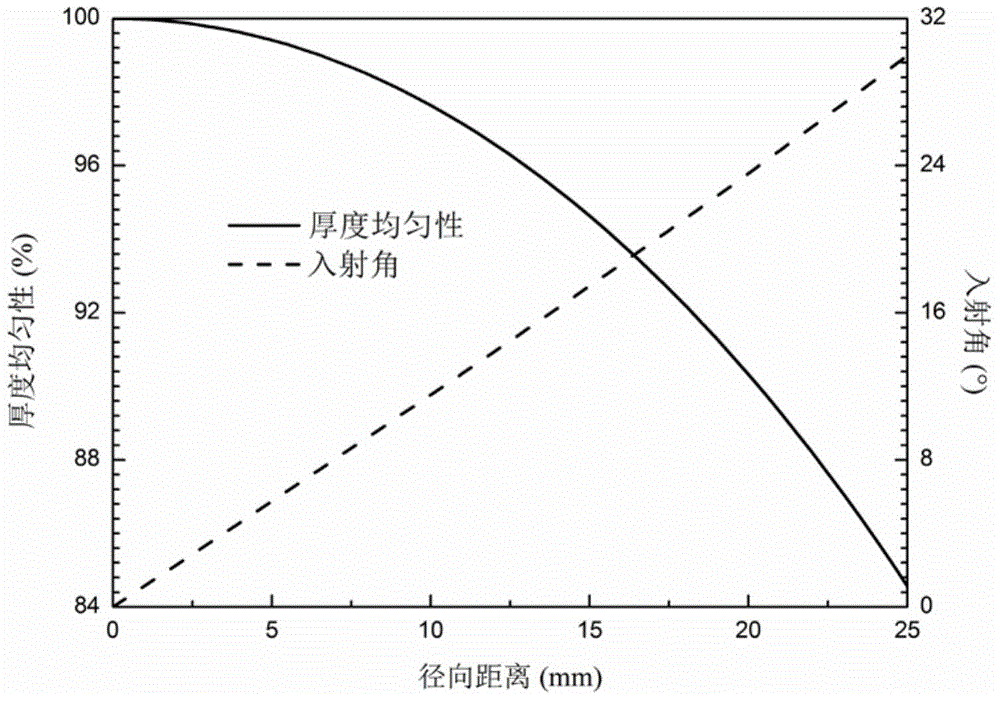

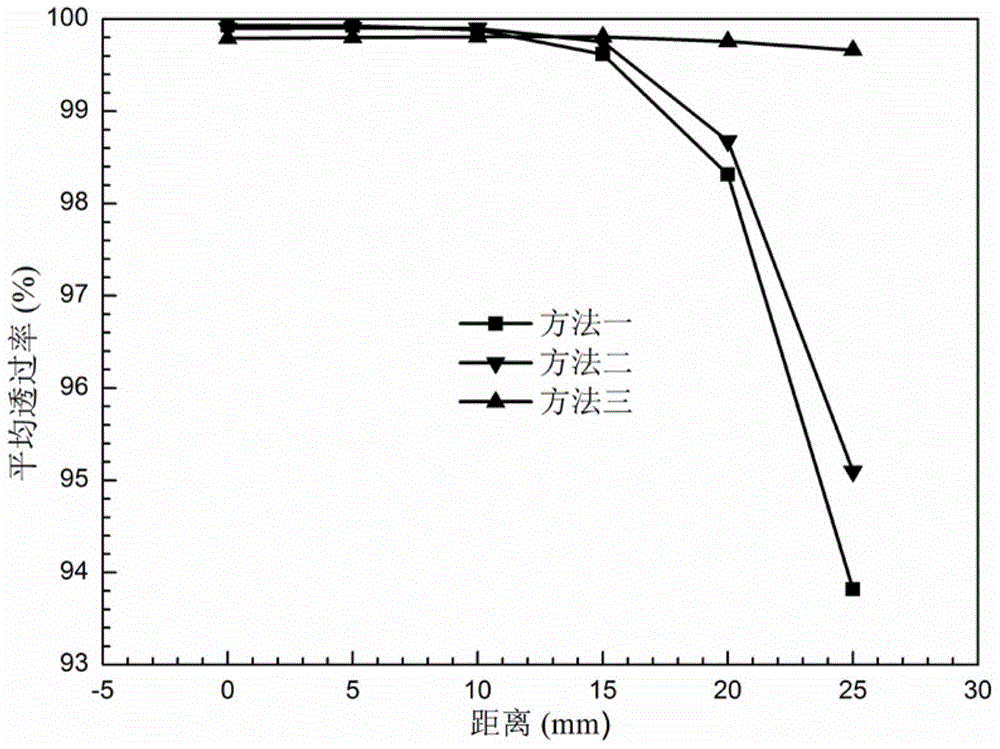

[0024] In the present invention, firstly, the thickness distribution of the optical film on the lens with a large curvature radius ratio is determined through experiments or theoretical analysis. Secondly, according to the light incident angle distribution and spectral performance requirements at each position on the lens with a large radius of curvature ratio, the numerical calculation method is used to globally optimize the design of the optical thin film system. Furthermore, the poor uniformity of the thickness of the optical film on the lens with a large radius of curvature ratio and the wide range of light incident angle distribution are solved, which brings difficulties to the design of the optical film film system of the lens with a large radius of curvature ratio. Below in conjunction with embodiment the present invention is further des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com