Apparatus of purifying CO2 in natural gas through low-temperature pressure swing adsorption (PSA) technology and method thereof

A pressure swing adsorption, CO2 technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., to achieve the effects of high purification, cost reduction, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

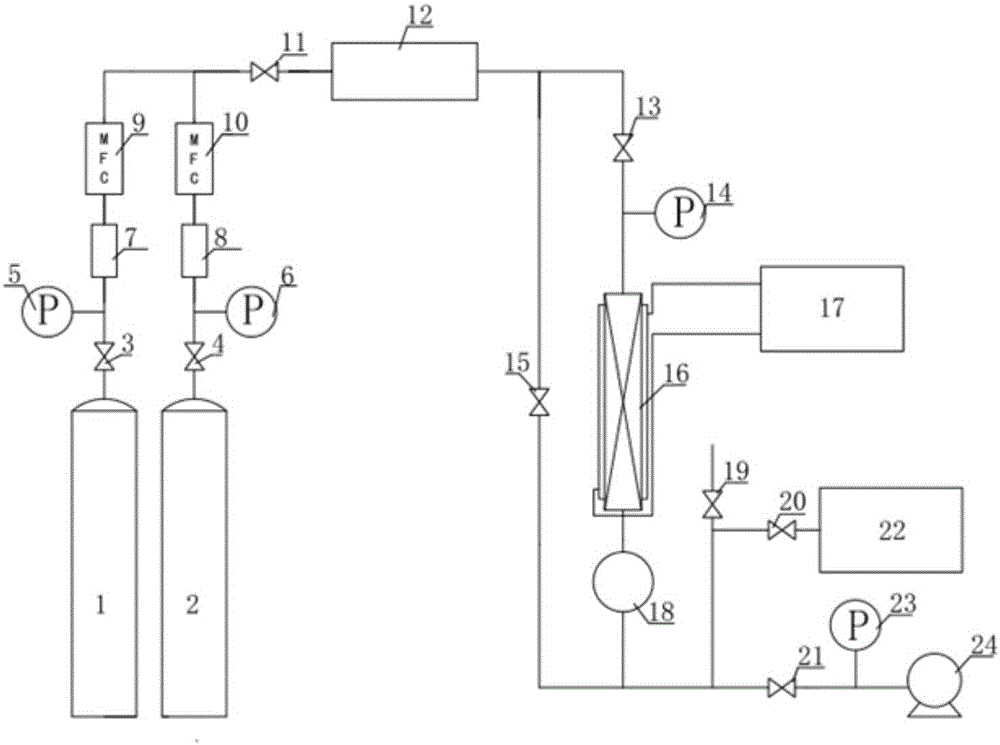

Method used

Image

Examples

Embodiment 1

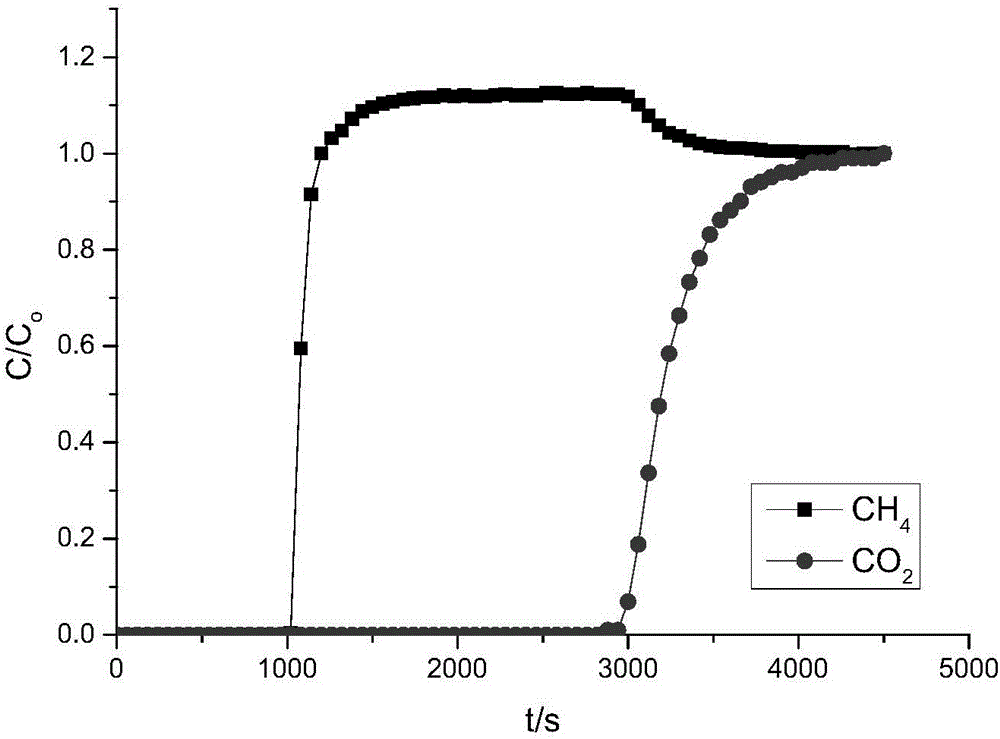

[0041] The pretreated natural gas with a pressure of 1.6MPa is pre-cooled to 0°C, and passed into the low-temperature pressure swing adsorption purification natural gas system that has been cooled to -10°C. The adsorber has been pre-loaded with coconut shell activated carbon and activated carbon particles. Diameter 1 ~ 3mm, specific surface area greater than 500m 2 / g. At this time, the low-temperature pressure swing adsorption purification natural gas system is in a low-temperature and high-pressure state, and the solid adsorbent will degrade the CO in natural gas. 2 Adsorbed, but little or no adsorption of CH 4 . The natural gas in the low temperature state continuously passes through the system, and the solid adsorbent continuously degrades the CO in the natural gas. 2 Adsorption is carried out to achieve the purpose of purifying natural gas. Dynamic breakthrough curves such as image 3 shown. CH 4 The breakthrough time is 1840s, CO 2 Breakthrough time is 6120s, CO ...

Embodiment 2

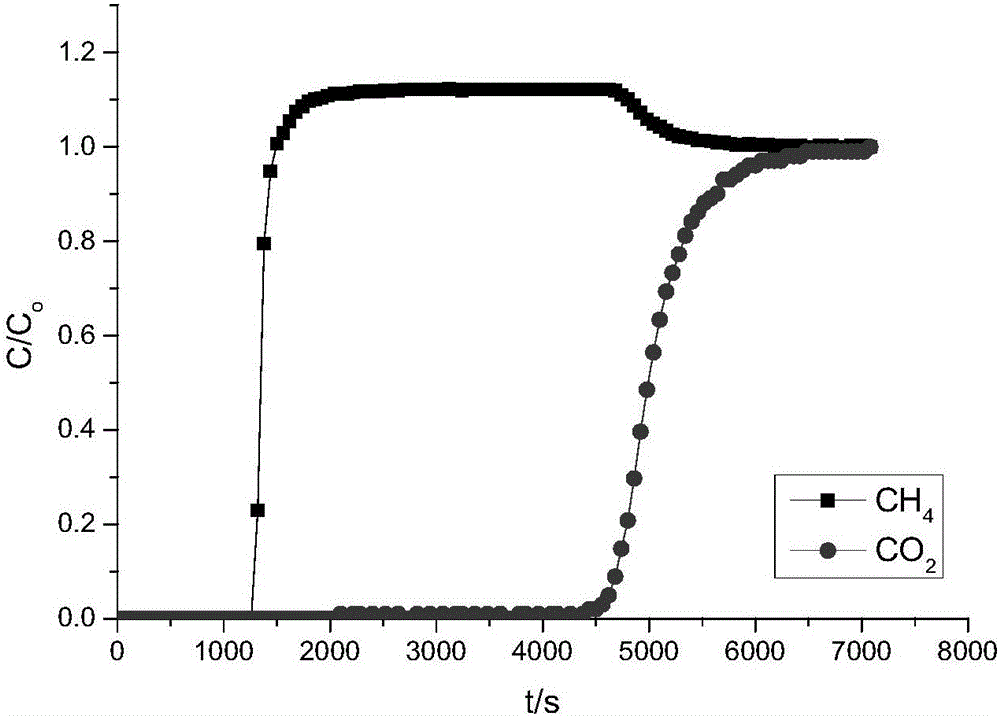

[0043] The pretreated natural gas with a pressure of 3.8MPa is pre-cooled to -10°C, and passed into the low-temperature pressure swing adsorption purification natural gas system that has been cooled to -20°C. The adsorber has been pre-loaded with 13X molecular sieve, molecular sieve particles Diameter 1.5 ~ 3mm, specific surface area greater than 650m 2 / g. At this time, the low-temperature pressure swing adsorption purification natural gas system is in a low-temperature and high-pressure state, and the solid adsorbent will degrade the CO in natural gas. 2 Adsorbed, but little or no adsorption of CH 4 . The natural gas in the low temperature state continuously passes through the system, and the solid adsorbent continuously degrades the CO in the natural gas. 2 Adsorption is carried out to achieve the purpose of purifying natural gas. Dynamic breakthrough curves such as Figure 5 shown. CH 4 The breakthrough time is 2240s, CO 2 Breakthrough time is 7210s, CO 2 / CH 4 T...

Embodiment 3

[0045] The pretreated natural gas with a pressure of 6.5MPa is pre-cooled to -10°C in the first stage, and passed into the low-temperature pressure swing adsorption purification natural gas system that has been cooled to -30°C. The adsorber has been pre-loaded with mesoporous material MCM- 41. The particle size of mesoporous materials is 2-4mm, and the specific surface area is greater than 800m 2 / g. At this time, the low-temperature pressure swing adsorption purification natural gas system is in a low-temperature and high-pressure state, and the solid adsorbent will degrade the CO in natural gas. 2 Adsorbed, but little or no adsorption of CH 4 . The natural gas in the low temperature state continuously passes through the system, and the solid adsorbent continuously degrades the CO in the natural gas. 2 Adsorption is carried out to achieve the purpose of purifying natural gas. Dynamic breakthrough curves such as Figure 7 shown. CH 4 The breakthrough time is 3140s, CO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com