Water-based high-fullness clear primer and preparation method thereof

A clear primer, water-based technology, applied in the field of coatings, can solve problems such as non-conforming to green, environmental protection, opacity and transparency, and whitening of the paint film, and achieve the effect of excellent fullness, good transparency, and easy polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

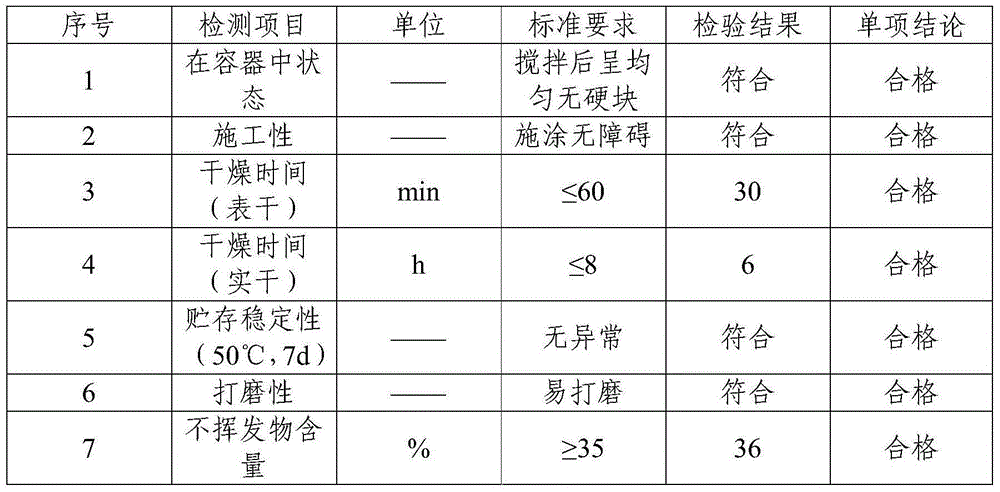

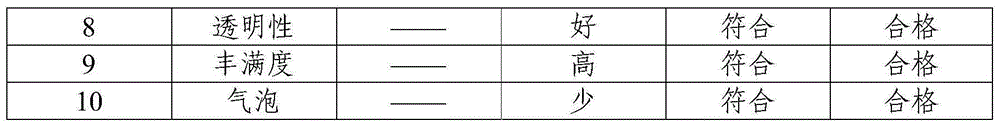

Examples

Embodiment 1

[0075] The preparation of embodiment 1 water-based high plump clear primer

[0076] 1. Put A1 and A2 into the dispersing tank in turn, disperse at 600r / min for 5 minutes, then put in B1, B2 and B3, and stir evenly;

[0077] 2. In the container bucket, first use C1 to dilute C2 and mix well, then add C3 to the bucket and mix well, then add C4 to the bucket to dilute and mix well. After fully mixing and stirring in the large bucket, pour in a small barrel, slowly add it into the dispersion tank in a linear shape, and disperse at 1000r / min for 15 minutes until the scraper has no oil shrinkage;

[0078] 3) Weigh D1 accurately, add half of the added amount first, stir at medium speed, and then add the remaining D1 and D2. A water-based high plump clear primer with a viscosity of 85-90KU / 25°C was obtained.

[0079] Among them, each component and its dosage are:

[0080] A1: acrylic resin 70kg;

[0081] A2: 5kg of water-based polyurethane resin;

[0082] B1: fungicide 0.1kg;

...

Embodiment 2

[0095] The preparation of embodiment 2 water-based high plump clear primer

[0096] 1. Put A1 and A2 into the dispersing tank in turn, disperse at 800r / min for 5 minutes, then put in B1, B2 and B3, and stir evenly;

[0097] 2. In the container bucket, first use C1 to dilute C2 and mix well, then add C3 to the bucket and mix well, then add C4 to the bucket to dilute and mix well. After fully mixing and stirring in the large bucket, pour in a small barrel, slowly add it into the dispersion tank in a linear shape, and disperse at 1200r / min for 15 minutes until the scraper has no oil shrinkage;

[0098] 3) Weigh D1 accurately, add half of the added amount first, stir at medium speed and then add D1 and D2. A water-based high plump clear primer with a viscosity of 85-90KU / 25°C was obtained.

[0099] Among them, each component and its dosage are:

[0100] A1: acrylic resin 75kg;

[0101] A2: 10kg of water-based polyurethane resin;

[0102] B1: fungicide 0.2kg;

[0103] B2: wat...

Embodiment 3

[0115] Example 3 Water-based high plump clear primer

[0116] The water-based high plump clear primer prepared in Example 1 was mixed with water in a weight ratio of 100:10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com