A method for degrading nicotine content in tobacco waste by using high-temperature composting

A technology of tobacco waste and high-temperature composting, which is applied in the preparation and application of fertilizer mixtures and organic fertilizers. It can solve the problems of long decomposing time, inability to return directly to the field, and inability to be suitable for soil, etc., and achieves fast degradation and easy operation. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

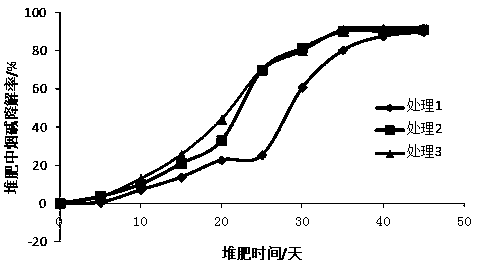

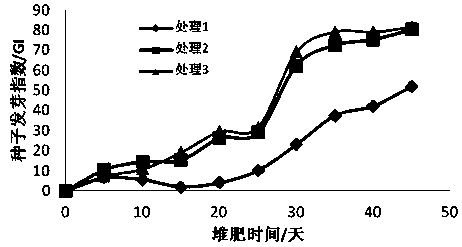

[0024] Example 1 Effect of Chemical Nitrogen Fertilizer on Nicotine Degradation Rate in High Temperature Composting of Tobacco Waste

[0025] The experiment was carried out at the teaching and practice base of the Department of Agricultural Resources of Hunan Agricultural University, using tobacco waste as compost raw materials. Tobacco waste comes from Liuyang Tianfu Rebaking Factory. Before high-temperature composting, the tobacco waste is dried, crushed, and passed through a 10-mesh sieve. The moisture, total carbon and total nitrogen contents of tobacco waste were 15.3%, 53.4% and 2.13%, respectively, and the C / N ratio was 25.07.

[0026] Three treatments were set up in the experiment, treatment 1: tobacco waste; treatment 2: adjusting the C / N ratio of tobacco waste with urea = 20; treatment 3: adjusting the C / N ratio of tobacco waste with ammonium sulfate = 20. Adjust the moisture content to 65% before composting and fermentation. After each treatment is stirred and mi...

Embodiment 2

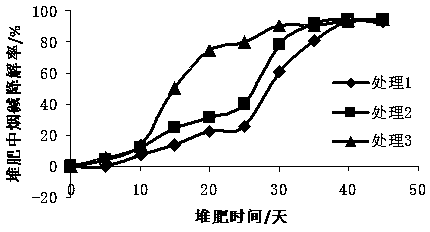

[0030] Example 2 Effect of chicken manure addition on nicotine degradation rate in high temperature composting of tobacco waste

[0031] The experiment was carried out at the teaching and practice base of the Agricultural Resources Department of Hunan Agricultural University, using tobacco waste and chicken manure as compost materials. Tobacco waste comes from Liuyang Tianfu Rebaking Factory. Before high-temperature composting, the tobacco waste is dried, crushed, and passed through a 10-mesh sieve. The moisture, total carbon and total nitrogen contents of tobacco waste were 15.3%, 53.4% and 2.13%, respectively, and the C / N ratio was 25.07. The moisture, total carbon and total nitrogen contents of chicken manure were 16.4%, 50.2% and 2.91%, respectively, and the C / N ratio was 17.25.

[0032] Three treatments were set up in the experiment, treatment 1: tobacco waste; treatment 2: adjusting the C / N ratio of tobacco waste with chicken manure = 23; treatment 3: adjusting the C / ...

Embodiment 3

[0036]Example 3 Effect of calcium magnesium phosphate fertilizer and phosphate rock powder on nicotine degradation rate in high temperature composting of tobacco waste

[0037] The experiment was carried out at the teaching and practice base of the Agricultural Resources Department of Hunan Agricultural University, using tobacco waste, chicken manure calcium magnesium phosphate fertilizer and phosphate rock powder as compost materials. Tobacco waste comes from Liuyang Tianfu Rebaking Factory. Before high-temperature composting, the tobacco waste is dried, crushed, and passed through a 10-mesh sieve. The moisture, total carbon and total nitrogen contents of tobacco waste were 15.3%, 53.4% and 2.13%, respectively, and the C / N ratio was 25.07. The moisture, total carbon and total nitrogen contents of chicken manure were 16.4%, 50.2% and 2.91%, respectively, and the C / N ratio was 17.25.

[0038] Three treatments were set up in the experiment, treatment 1: tobacco waste; treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com