Loading and unloading system for container

A technology for loading and unloading systems and containers, applied in the field of machinery, can solve the problems of low safety factor and troublesome unloading operations, and achieve the effects of improving stability, fast and convenient loading and unloading, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

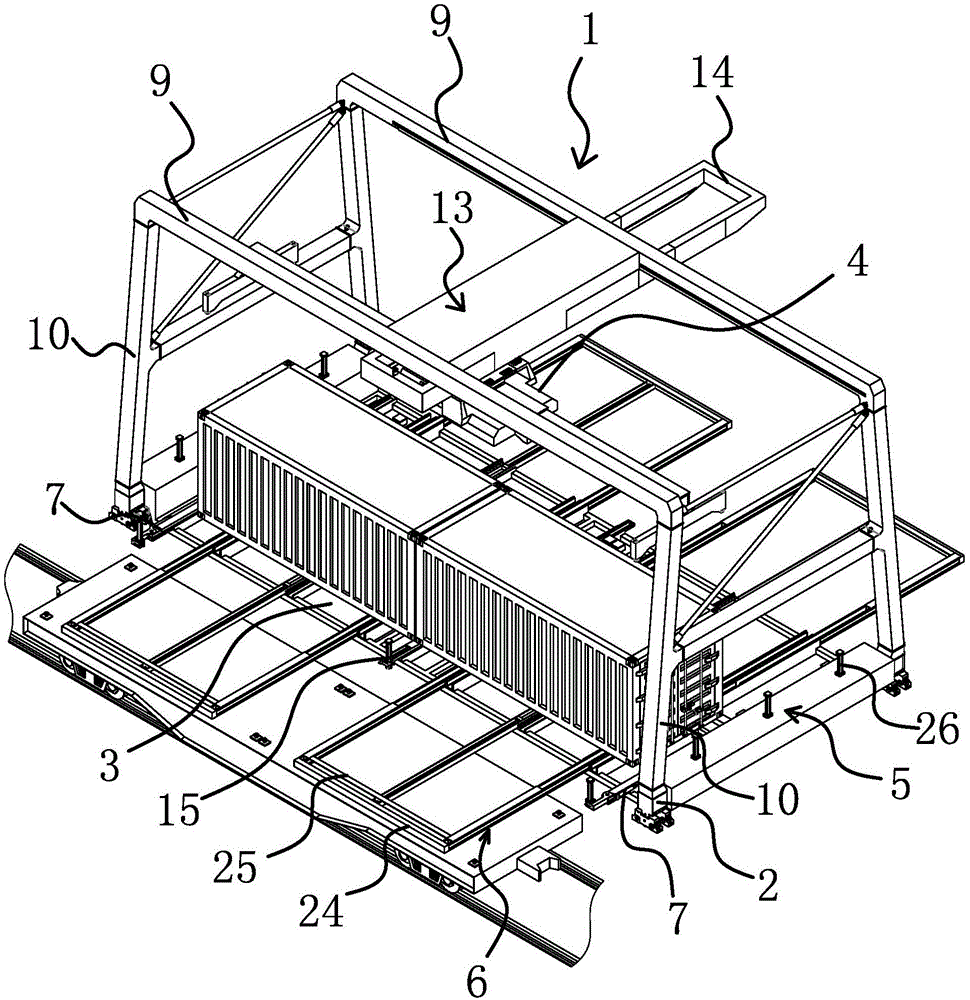

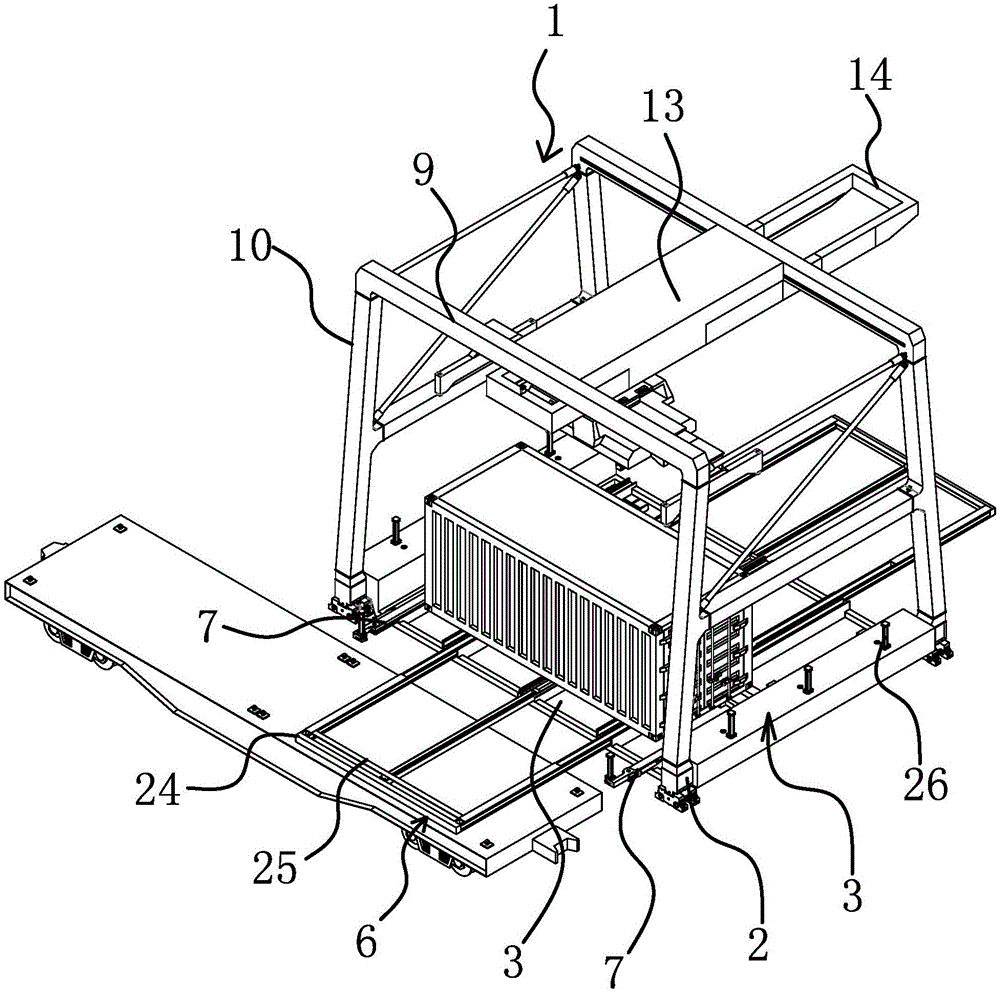

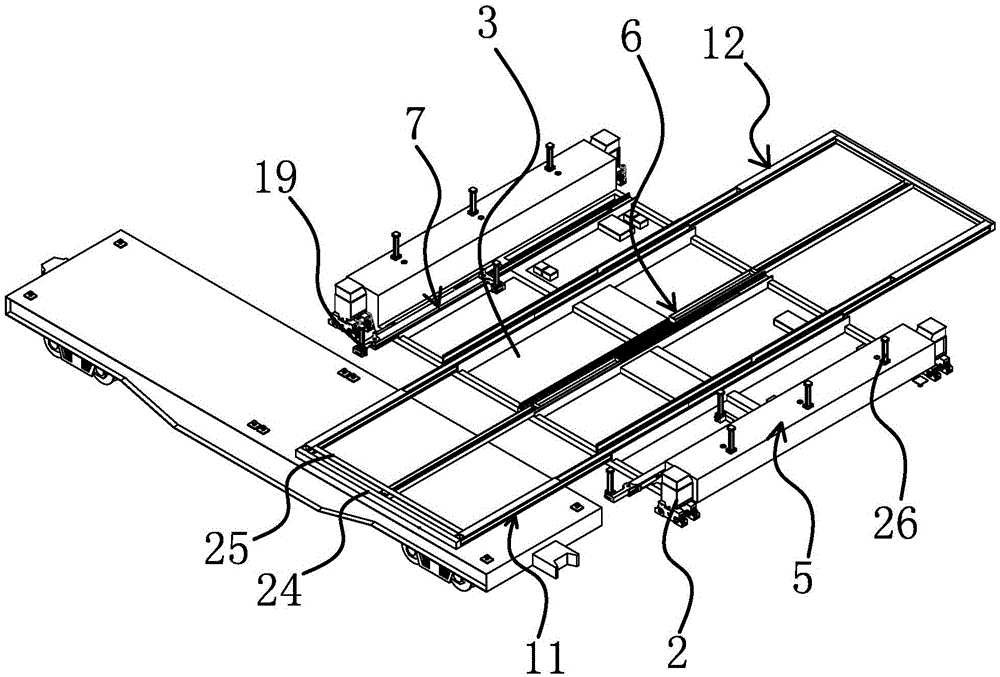

[0031] Such as Figure 1-6 As shown, the loading and unloading system includes a frame body 1, the frame body 1 includes a walking frame 2 and a base plate 3 arranged on the walking frame 2, the frame body 1 is provided with a boom 4, the boom 4 is located above the base plate 3, the base plate 3 and An adjustment structure 5 capable of adjusting the height of the base plate 3 is provided between the walking frames 2. At least one mobile support 6 is provided on the base plate 3. The mobile support 6 is slidably connected to the base plate 3 and can stretch out from the side of the base plate 3. The mobile support 6 is perpendicular to Both sides of mobile support 6 moving directions are respectively provided with bar-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com