Double-trolley drive mechanism used for traversing type double-trolley quay crane

A technology of driving mechanism and double trolleys, which is applied in the direction of load block, load hanging components, transportation and packaging, etc., and can solve problems such as winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

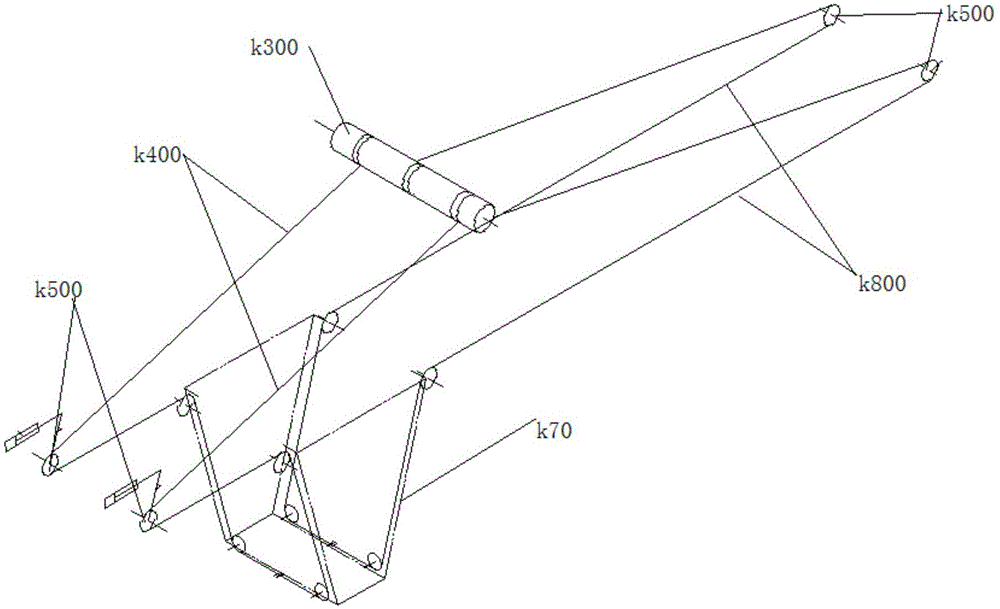

[0091] This embodiment provides a double-trolley driving mechanism for use on a quay bridge with double trolleys. The double trolley driving mechanism includes a double trolley lifting mechanism, a double trolley traction mechanism and a double trolley winding system. Wherein, the double trolley lifting mechanism includes an upper trolley lifting mechanism b1 for driving the upper trolley to lift or land and a lower trolley lifting mechanism b2 for driving the lower trolley to lift or land; the double trolley traction mechanism It includes the upper trolley traction mechanism c1 for driving the upper trolley to move forward and backward horizontally and the lower trolley traction mechanism c2 for driving the lower trolley to move forward and backward horizontally; the double trolley winding system is connected to the double trolley lifting mechanism and the double trolley traction mechanism, the double-trolley winding system can drive the double-trolley spreader to lift or lan...

Embodiment 2

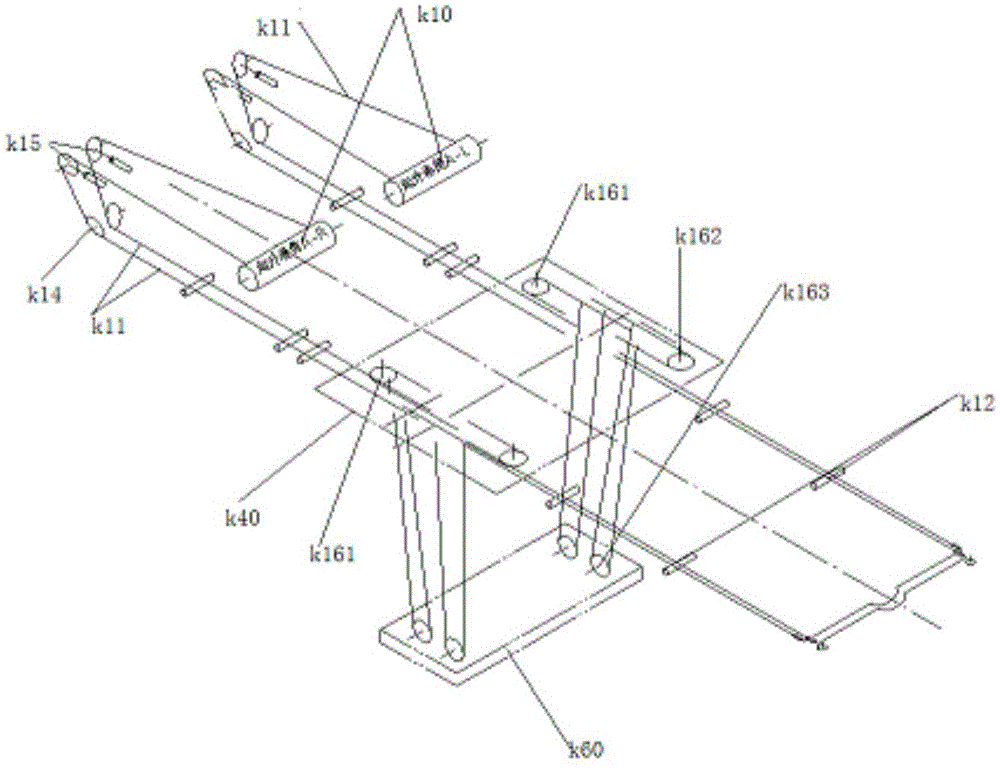

[0124] This embodiment provides a double-trolley winding system, which is a deformation based on Embodiment 1. It differs from Embodiment 1 in that the arrangement and implementation of the third pulley block in the lifting and winding subsystem of the upper trolley Example 1 is different. Specifically, in this embodiment, as Figure 10 As shown, the third pulley set includes the fourteenth pulley k163 located at the upper part of the upper spreader k60, the fifteenth pulley k164 located at the lower part of the upper spreader k60, and the extension of the first hoisting wire rope k11 from the first horizontal pulley k161. The outlet goes around the fourteenth pulley k163 from the top, then goes around the fourteenth pulley k163 from the bottom of the fifteenth pulley k164 and goes out from the fourteenth pulley 163, and finally is arranged on the bottom of the upper spreader k60.

Embodiment 3

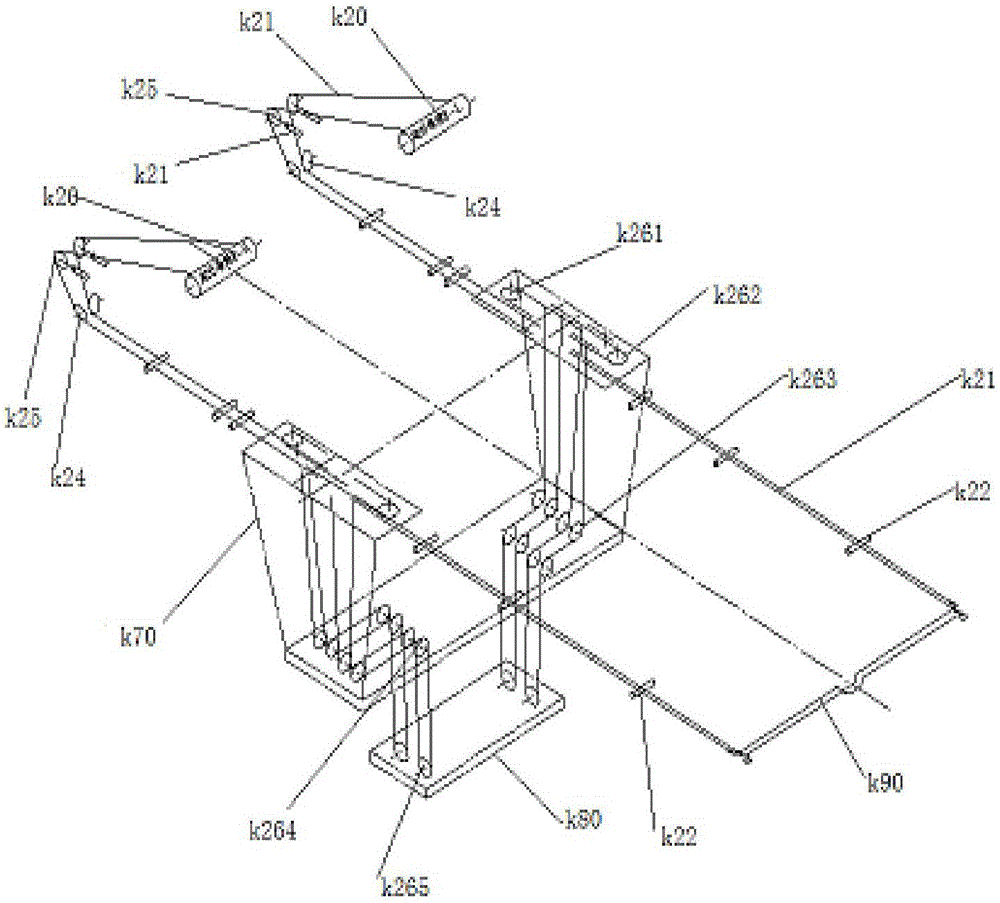

[0126] This embodiment provides a double trolley winding system, which is a modification based on Embodiment 1 or 2. The difference between it and Embodiment 1 or 2 is that the second vertical The setting mode of reversing block of pulleys is different from embodiment 1 or 2. Specifically, in this embodiment, as Figure 11 As shown, the second vertical redirecting pulley block k26 includes two fourth horizontal pulleys k261 and fifth vertical pulleys k262 arranged at a certain distance on the top of the lower trolley k70, and the sixth pulley k267 arranged on the lower trolley k70 , several parallel seventh pulleys k263 arranged on the upper part of the lower spreader k80, several parallel eighth pulleys k264 arranged on the upper part of the lower spreader k80, and the first pulley k264 arranged on the bottom of the lower spreader k80 Nine pulleys k265, the fifth vertical pulley k262 is farther away from the second horizontal diverting pulley group k24 than the fourth horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com