Intelligent card tin dipping equipment with soldering tin protection function

A protection function, smart card technology, applied in welding equipment, metal processing equipment, tin feeding device, etc., can solve the problems of high cost, affecting welding quality, falling on the card 1 or chip, etc., to achieve low cost and improve welding Quality, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

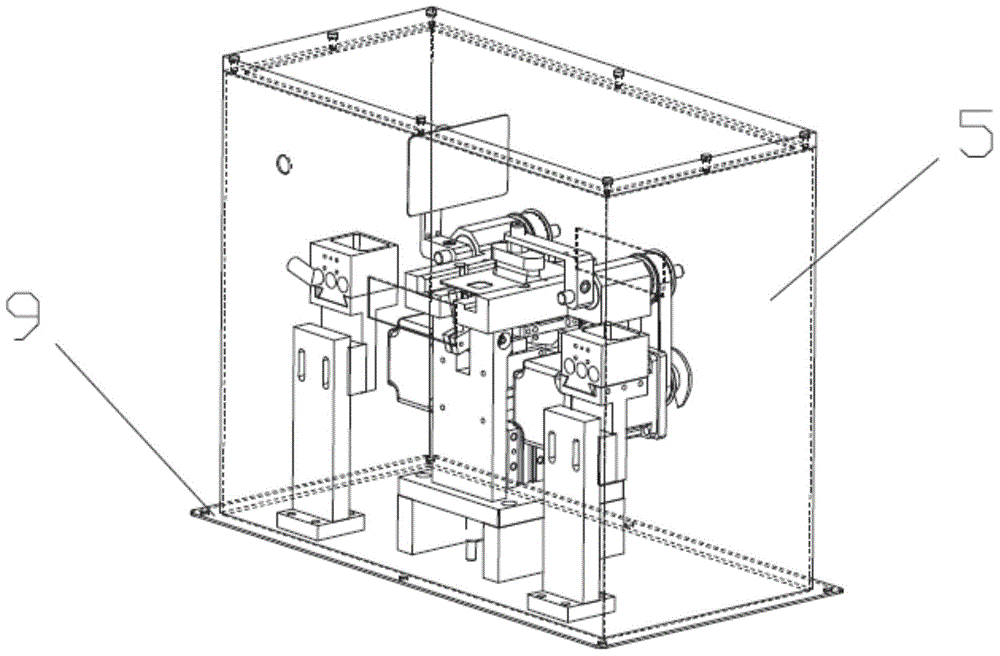

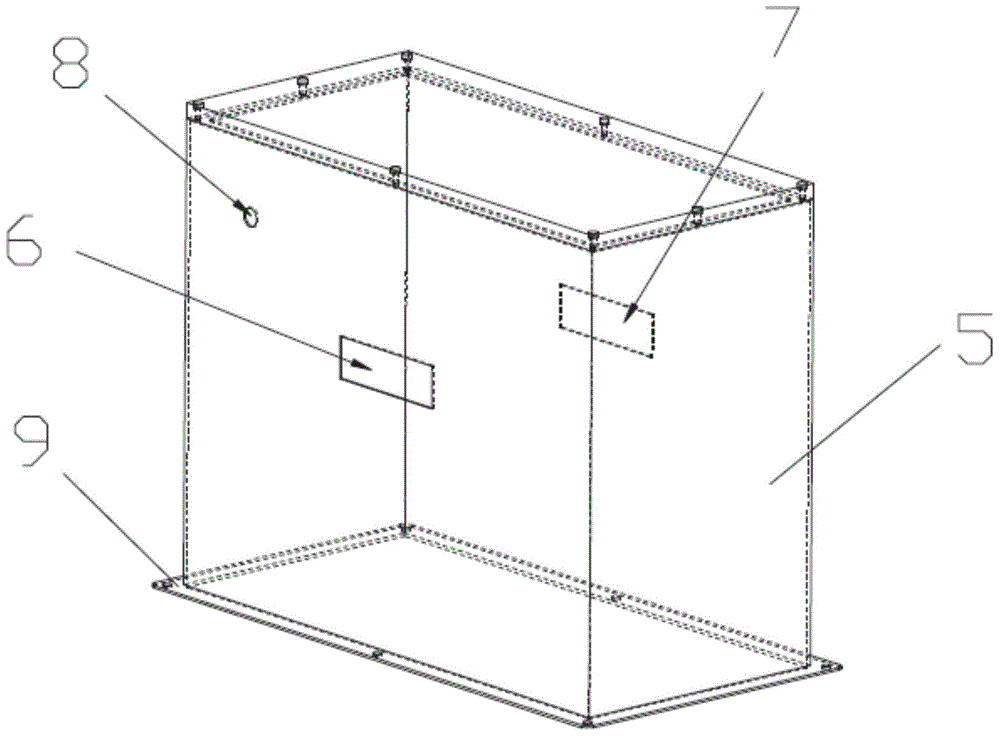

[0030] See figure 2 The smart card soldering equipment with solder protection function of the present invention includes a soldering device, a card conveying mechanism and a sealing cover 5. The soldering device is arranged in the sealing cover 5, and the card conveying mechanism is removed from the sealing cover 5. Through; The sealing cover 5 is filled with inert gas.

[0031] See figure 2 with image 3 An inert gas supplement device is connected to the sealing cover 5, which includes an inert gas storage tank, a gas pipe connecting the inert gas storage tank and the sealing cover 5, a gas pump connected to the gas pipe, and a solenoid valve. The purpose of the above-mentioned inert gas replenishing device is to replenish the inert gas in the sealing cover 5 in time. Since the card co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com