Energy-saving protective cover for cooking pressure cooker

一种高压锅、节能罩的技术,应用在压力锅、烹调器的外壳/套等方向,能够解决易被烫痛或烫伤、金属表面外露面积大、不利保温等问题,达到减少烫痛或烫伤的机会、良好节能和保温效果、安全防护作用好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

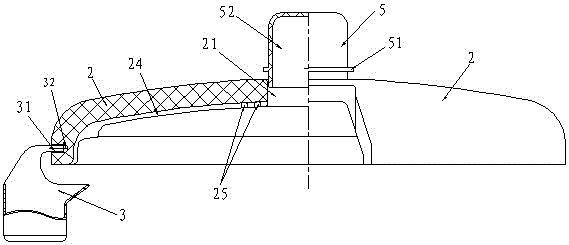

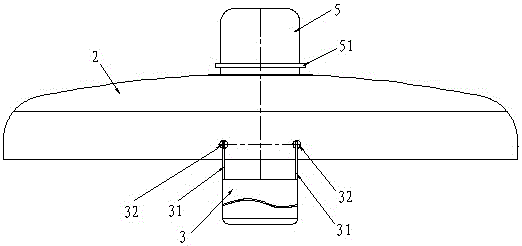

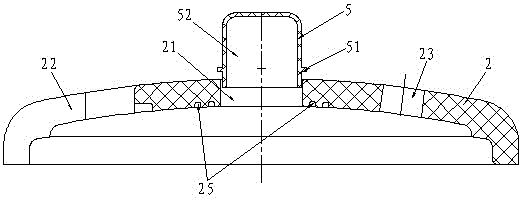

[0026] The protective energy-saving cover for the cooking pressure cooker of Embodiment 1 of the present invention (for the structure see Figure 1-Figure 6 ), which is characterized in that: it includes a heat shield 2 made of a material with heat insulation effect, which is set on the lid 1 of the pressure cooker and is used to cover its outer surface; the heat shield 2 is made of a Made of foamed plastic material; the heat shield 2 is provided with a valve position hole 21 for avoiding the pressure limiting valve bonnet 11, and there is a suitable exhaust gap between the valve position hole 21 and the peripheral side of the bonnet 11, so as to The gas ejected from the valve cap 11 can be discharged from the gap; the heat shield 2 is provided with a handle groove 22 for avoiding the cover handle 13 .

[0027] The heat shield 2 is provided with a safety hole 23 for avoiding the safety valve 14, so that the function of the safety valve 14 will not be affected. According to th...

Embodiment 2

[0043] The protective energy-saving cover of the cooking pressure cooker of the second embodiment of the present invention (for the structure see Figure 7-Figure 9 ). In order to make the function of the protective energy-saving cover of the present invention more perfect and make it easier to implement and apply, on the basis of the first embodiment of the present invention, the second embodiment of the present invention further constructs the following structure, and its benefits are also described later.

[0044] The outer surface of the above-mentioned heat shield 2 is provided with a shell membrane 4 made of a plastic material with suitable strength and integrated therewith. The constructed shell film 4 is conducive to protecting the heat shield 2, so as to overcome the shortcomings that the heat shield 2 made of foamed plastic material is easily polluted and easily deformed and damaged, so that the heat shield 2 It can better adapt to the requirements of the protective...

Embodiment 3

[0046] The protective energy-saving cover of the cooking pressure cooker of the third embodiment of the present invention (for the structure see Figure 10-Figure 12 ). In order to make the function of the protective energy-saving cover of the present invention more perfect and make it easier to implement and apply, on the basis of the first embodiment of the present invention, the second embodiment of the present invention further constructs the following structure, and its benefits are also described later.

[0047] Further configuration 1: the outer side of the above-mentioned heat shield 2 is provided with a cover shell 6 nested with it; the cover shell 6 is provided with a corresponding valve position hole 21 for avoiding the bonnet 11 and a hole for avoiding the safety valve 14 The safety hole 23 and the relief hole groove for avoiding other safety components on the pot cover 1 .

[0048] The constructed cover shell 6 is beneficial to protect the heat shield 2, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com