Plies for cardboard from in-line production methods

A technology for cardboard and paper, applied in the field of layers containing mixed materials, which can solve the problems of reduced tensile strength and tensile stiffness of paper, poor retention, and increased wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

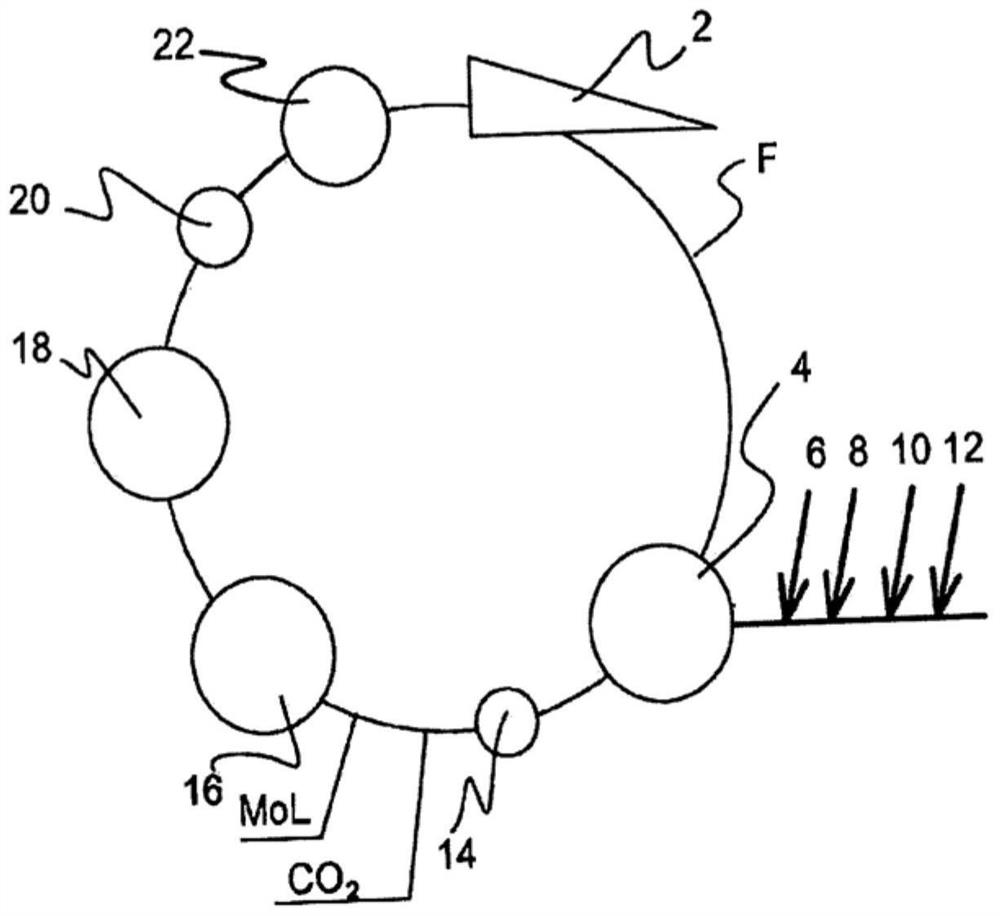

[0082] Trials were carried out in a pilot paper machine. The objective of this test is to simulate the face ply of multi-ply paperboard.

[0083] Supplies are 100% bleached birch wood refined to 26SR grade. The running speed was 80m / min and the grammage was 65gsm. Conventional paper chemicals used in board production, such as retention chemicals, hydrophobic sizing agents, etc., are used. These parameters were kept constant during the experiment.

[0084] Table 1 below shows an overview of how the test was performed and the chemicals used therein.

[0085] The addition of CMC (carboxymethyl cellulose) was not necessary, however, a slight improvement in strength could be noticed. However, CMC had no adverse effect on thread retention and brightness.

[0086] Starch is usually added as it imparts some strength without major adverse effects.

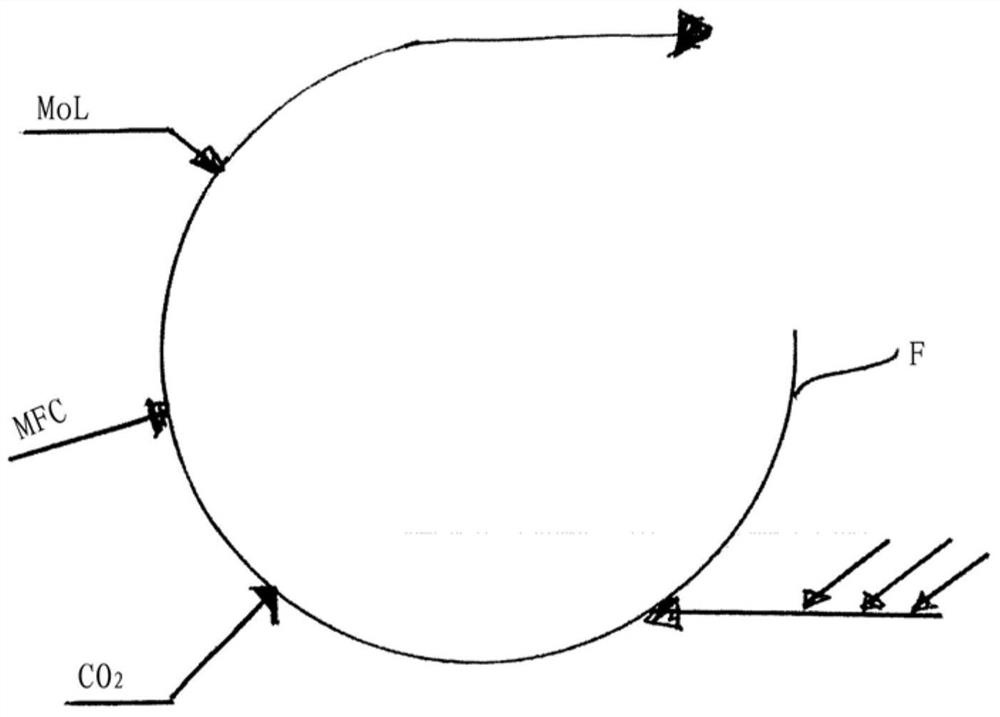

[0087] In Example 1, the mixing of MFC and starch into milk of lime was carried out and its ingredients were added or introduced int...

Embodiment 2

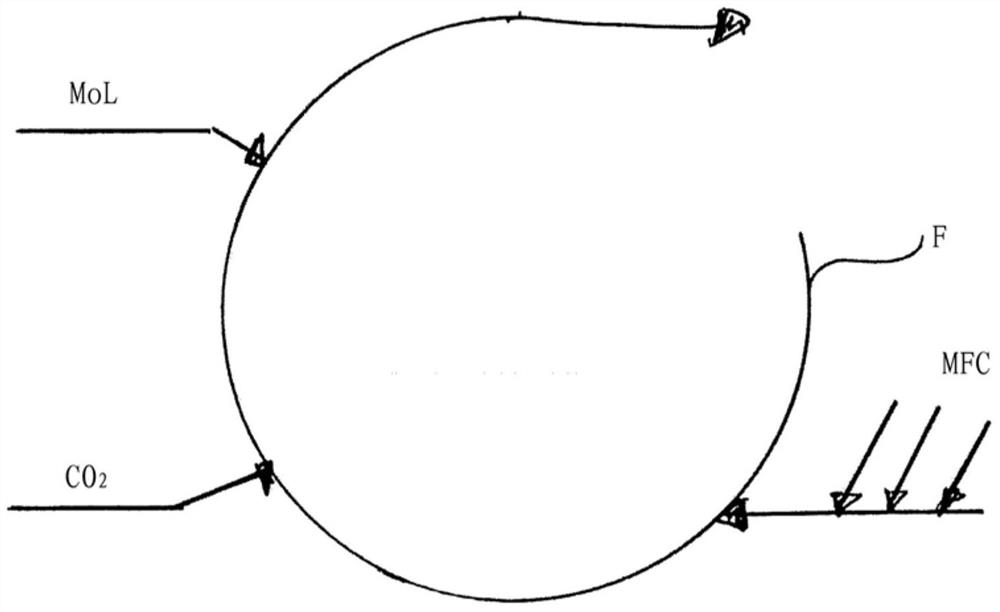

[0096] Example 2 shows that if the addition of MFC and starch substitute is compounded into a thick stock, much higher amounts are required for the same strength level and high porosity is lost. A Gurley hill porosity of 31s / 100ml indicates the low porosity of the paper layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com