Electric vehicle battery arrangement structure having buffer effect

An electric vehicle battery, battery placement technology, applied in secondary batteries, structural parts, battery pack components and other directions, can solve the problems of no buffer device, soaring battery box temperature, battery connection line detachment, etc., to improve service life, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

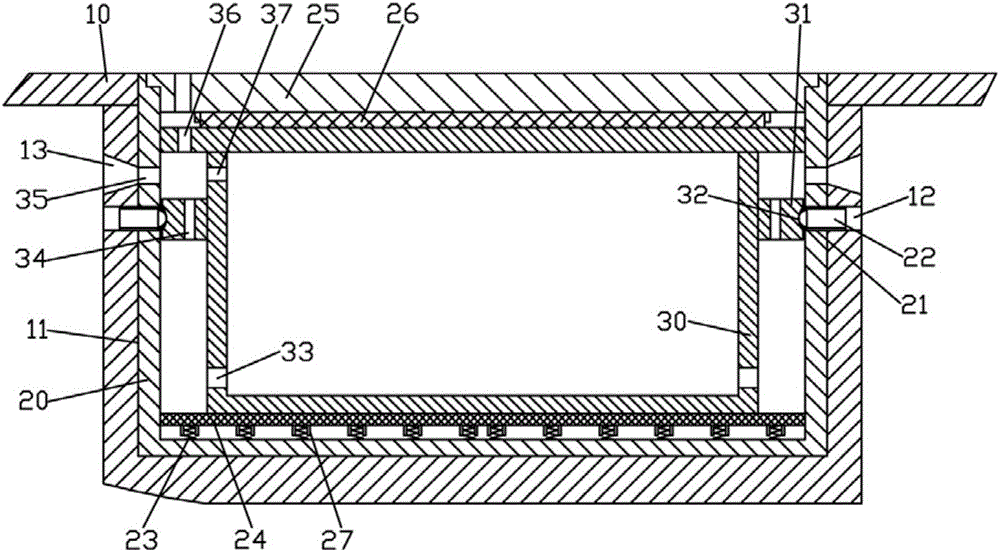

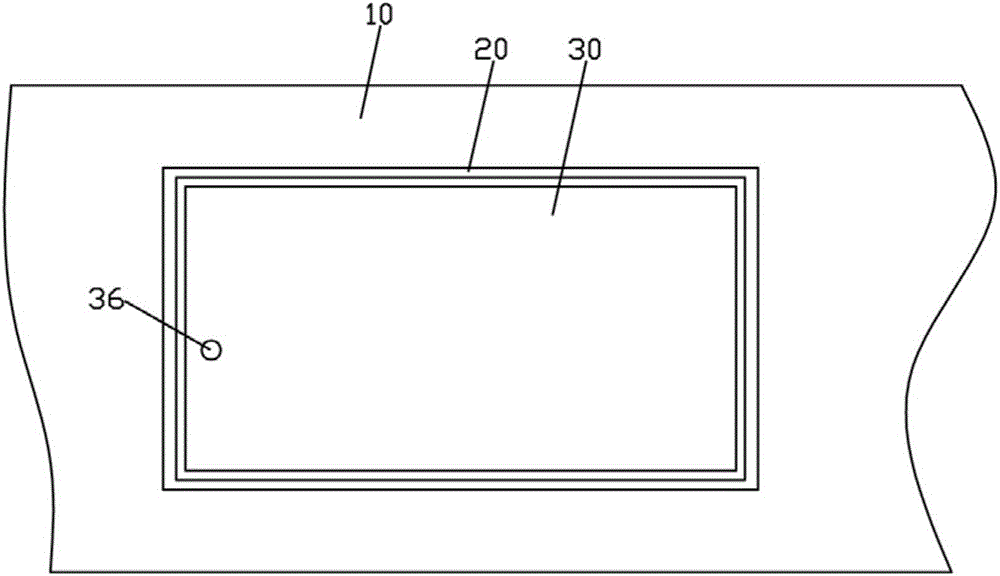

[0014] Examples, see e.g. Figures 1 to 2 As shown, a battery placement structure for an electric vehicle with a cushioning effect includes a vehicle frame 10, a battery placement groove 11 is provided in the middle of the vehicle frame 10, and a battery box protective case 20 is inserted and fixed in the battery placement groove 11, and the battery There are multiple screw through holes 21 on the side wall of the box protective case 20, and there are also multiple through holes 12 on the side wall of the battery placement groove 11, the through holes 12 correspond to the screw through holes 21 one by one, and the ball plunger 22 is screwed into the screw through hole 21, the battery box 30 is placed in the battery box protective shell 20, and the outer wall of the middle part of the battery box 30 has an annular positioning part 31, and the steel ball of the ball plunger 22 is nested in the annular positioning part. In the concave hole 32 on the part 31, a plurality of buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com