Automatic alumina sampling apparatus

An automatic sampling device and alumina technology, applied in the sampling device and other directions, can solve problems such as gaps, inability to accurately reflect the real situation of alumina entering the tank, etc., to achieve low cost, automatic sample collection, installation and disassembly process of multiple points and small quantities. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

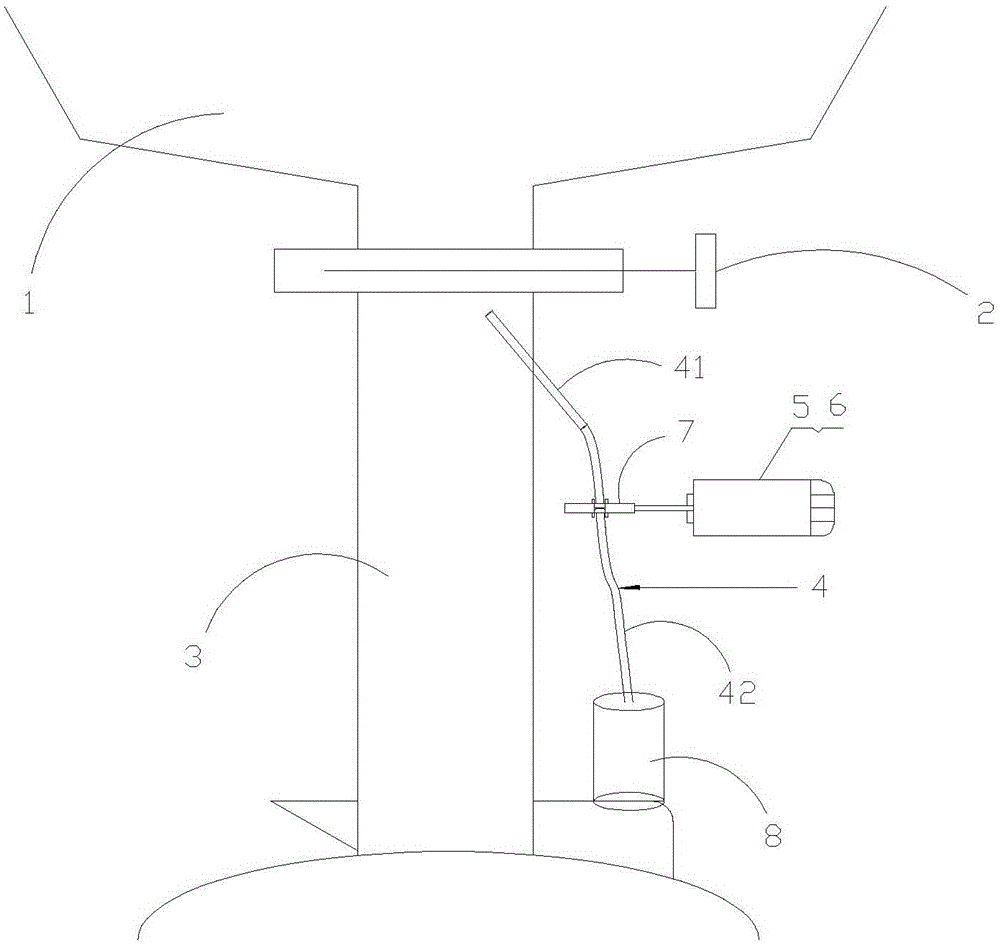

[0014] Such as figure 1 As shown, an automatic alumina sampling device of the present invention includes a sampling tube 4, an electric sampling butterfly valve 7 arranged on the sampling tube 4, a motor 6 located on one side of the electric sampling butterfly valve 7, and a motor 6 connected to the electric sampling tube 7, respectively. Sampling butterfly valve 7 and the reducer 5 of the motor 6, the reduction ratio of the reducer 5 is 1400:1. figure 1 Also shown in the figure are the alumina hopper 1, the feeding pipe 3 arranged at the bottom of the oxidation hopper 1, and the slide valve 2 arranged on the feeding pipe 3.

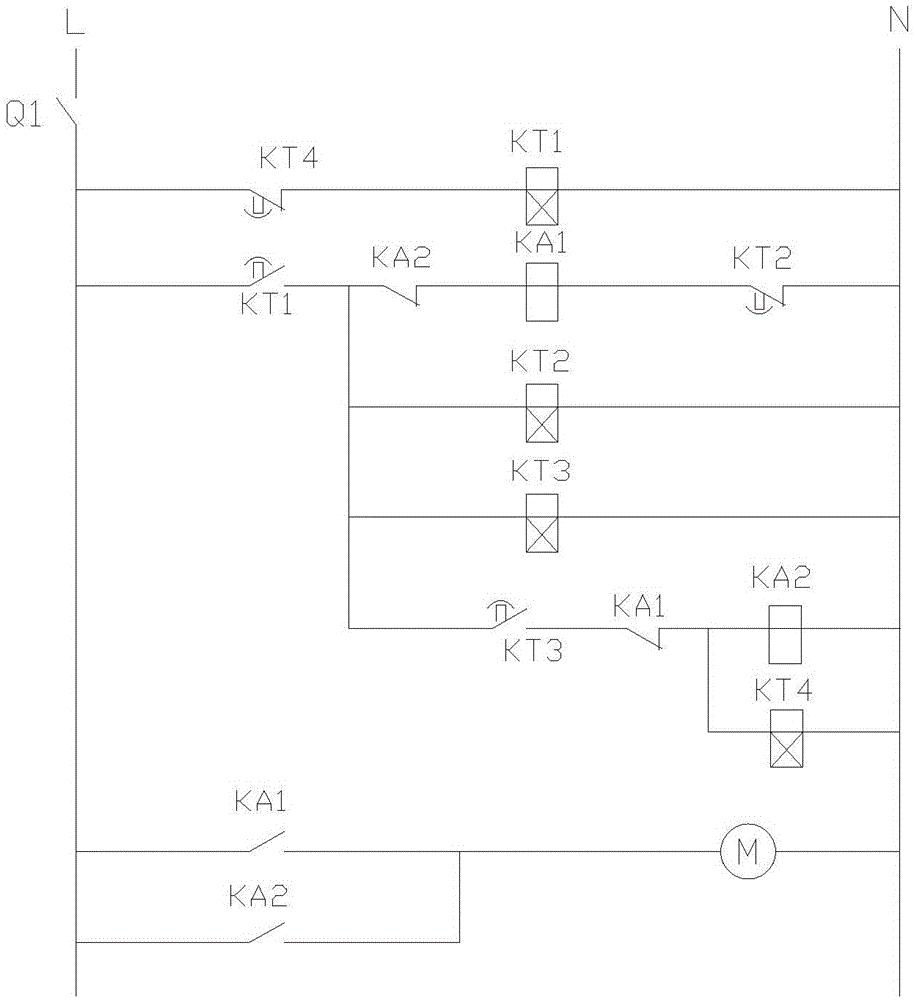

[0015] Such as figure 2 As shown, when the control power switch Q1 is turned on, KT1 is energized and starts timing. The timing period can be set by yourself, KT1 closes, KA1 acts, the motor rotates forward to open the valve, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com