Refrigerator return air system and method

A wind system and refrigerator technology, applied in lighting and heating equipment, cooling fluid circulation devices, home appliances, etc., can solve the problems of long airflow process, congestion of bottom return air, affecting return air efficiency, etc., to improve uniformity and temperature The uniformity of the airflow, the uniformity of the airflow distribution and the uniformity of the temperature, and the effect of reducing the partial congestion of the airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

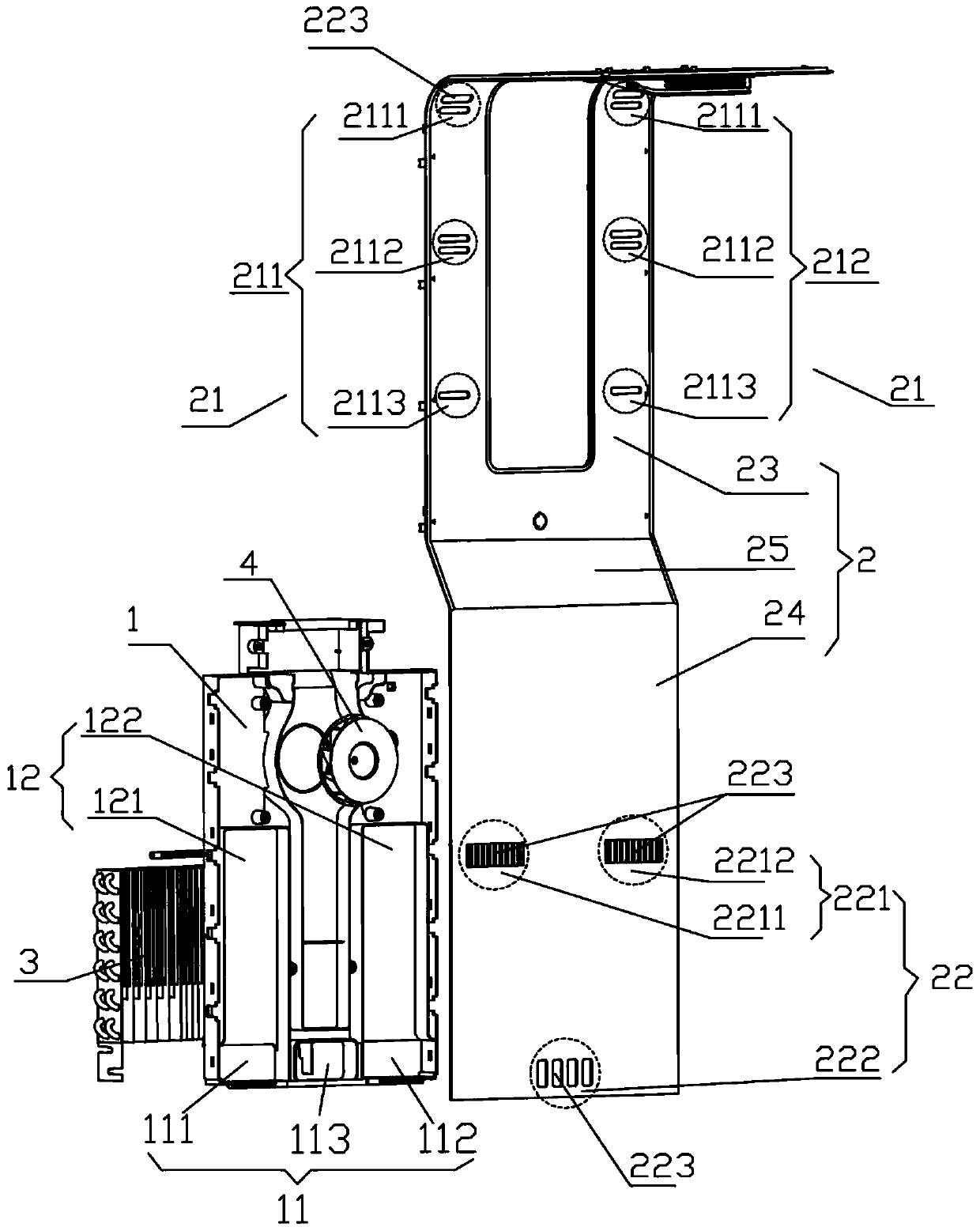

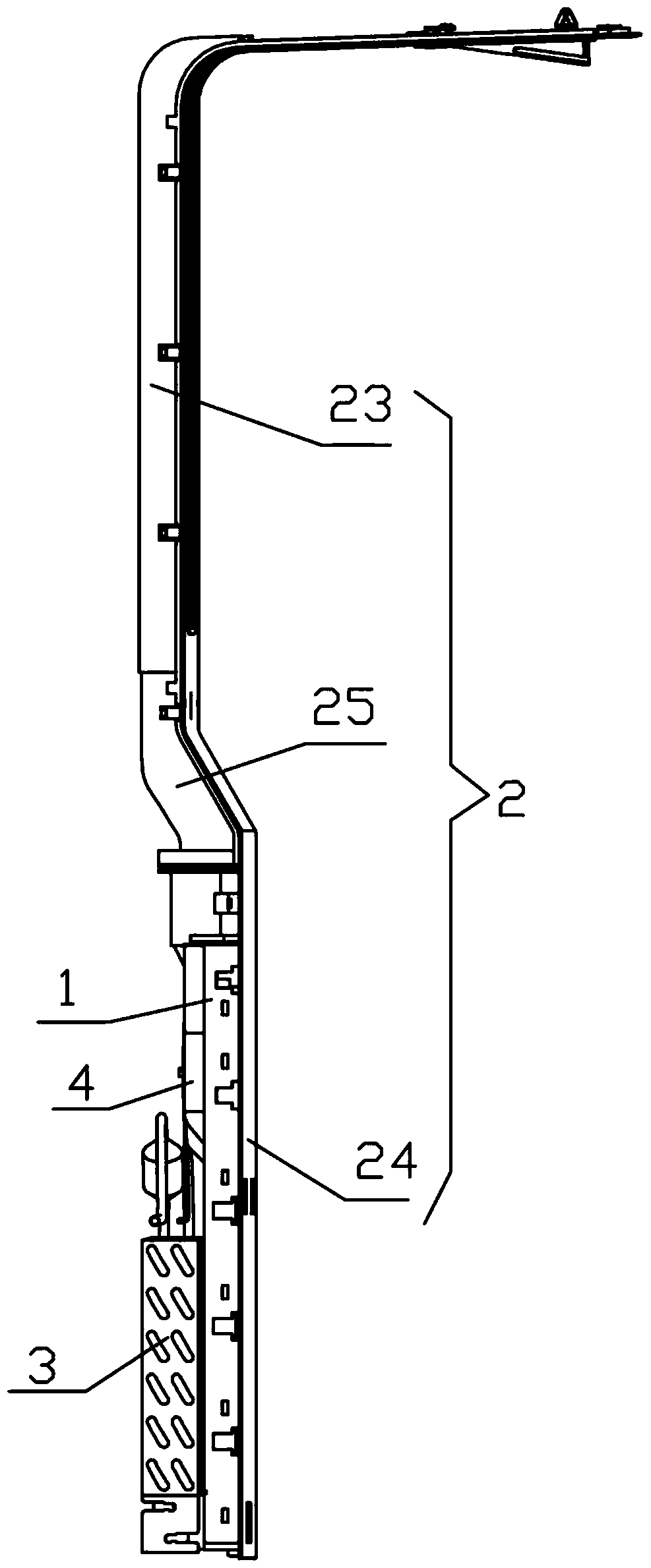

[0042] Such as figure 1 As shown, a refrigerator return air system in this embodiment includes an air duct main body 1, an air duct cover plate 2, a fan 4 and an evaporator 3 arranged on the back of the refrigerator box, and the air duct cover plate 2 covers the refrigerator box body. on the back of the refrigerator, the length of the air duct cover plate 2 is the same as the height of the refrigerator; figure 2 As shown, the air duct main body 1, the air duct cover plate 2 and the evaporator 3 are stacked in sequence to form a layered structure, the air duct main body 1 is clamped between the air duct cover plate 2 and the evaporator 3 in a plate shape, and the fan 4 is fixed Above the air duct main body 1. The air duct cover plate 2 includes an upper half 23 and a lower half 24, the upper half 23 and the lower half 24 are connected by a slant plate 25, the air duct main body 1 and the evaporator 3 are connected with the lower half of the air duct cover plate 2 24 connecte...

Embodiment 2

[0048] On the basis of Embodiment 1, this embodiment is further provided with a return air duct 12 on the air duct main body 1 .

[0049] Such as figure 1 As shown, the return air duct 12 is arranged above the return air duct 11 , and the return air duct 11 communicates with the return air duct 12 . The return air duct 12 is a groove provided on one side of the air duct main body 1, and the groove is in a rectangular parallelepiped structure. The return air duct 12 comprises a first return air duct 121 and a second return air duct 122, and the first return air duct 121 and the second return air duct 122 are symmetrically arranged on both sides of the fan 4; The air return channel 121 is on the same level as the first air return port 2211 and communicates with it, and the second return air channel 122 is on the same level as and communicates with the second air return port 2212 . By setting two return air ducts on the left and right, the air flow is separated into two bundles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com