A kind of anti-load pressure regulator pre-charging mechanism with selection function

A technology for selecting functions and pre-charging, which is applied to mechanical equipment, engine components, valve operation/release devices, etc., and can solve the problems of lack of switch selection function, inconvenient operation for pilots, and discomfort for pilots, preventing up and down. The effect of sliding, uniform force and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

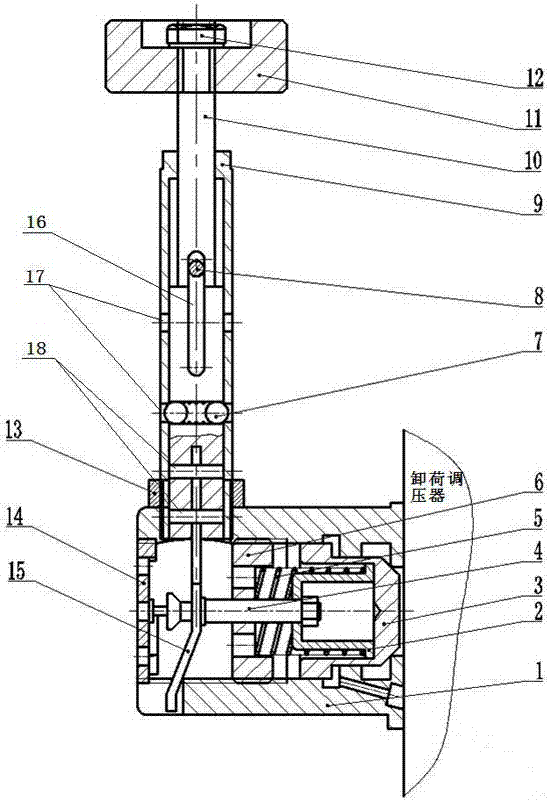

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0025] Such as figure 1 As shown, a pre-charging mechanism of anti-load pressure regulator with selection function, including a pre-charging housing 1 arranged on the course of the aircraft, a baffle 6, a pre-charging spring 5 and a valve 3 arranged in the housing , the valve 3 is facing the exhaust port of the anti-load pressure regulator, the pre-charge spring 5 is located between the baffle plate 6 and the valve 3; the top surface of the pre-charge housing 1 is fixed with a longitudinal support pipe frame 9 , the support pipe frame 9 is provided with an operating rod 10, the top of the operating rod 10 passes through the supporting pipe frame 9 upwards and is provided with an operating head 11, and the bottom of the operating rod 10 extends downwards to the inside of the pre-charged pressure housing 1 and is fixed with Pick 15, the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com