Water temperature control method and control system for AMT vehicle hydraulic retarder

A hydraulic retarder and water temperature control technology, which is applied in the direction of liquid resistance brakes, slack regulators, brake types, etc., can solve the problems of retarder braking capacity reduction, high engine water temperature, and limited engine power. To achieve the effect of enhanced cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

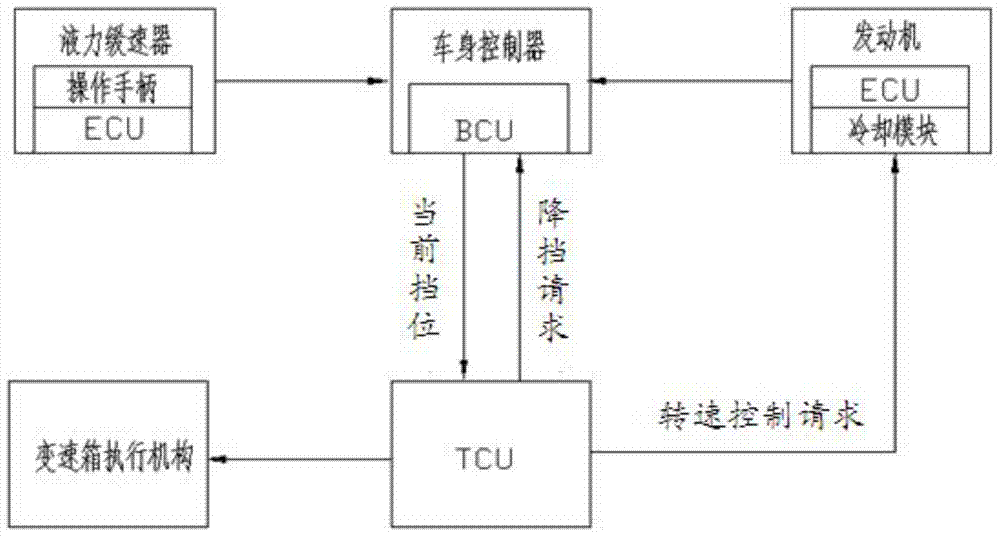

[0056] see figure 1 and figure 2 , Embodiment 1 of the present invention provides a water temperature control system for a hydraulic retarder of an AMT model, including a body controller BCU, an engine electronic control unit ECU, an automatic transmission electronic control unit TCU, a gearbox actuator and a hydraulic retarder. Transmission, the engine electronic control unit ECU, automatic transmission electronic control unit TCU and hydraulic retarder are all connected to the body controller BCU;

[0057] The body controller BCU is respectively connected with the engine electronic control unit ECU, the automatic transmission electronic control unit TCU and the hydraulic retarder through the CAN bus; it is used to send the working state of the hydraulic retarder to the CAN On the bus, when the BCU receives its status, it starts to query the current water temperature value. If the water temperature is higher than the set warning temperature, the BCU receives the current eng...

Embodiment 2

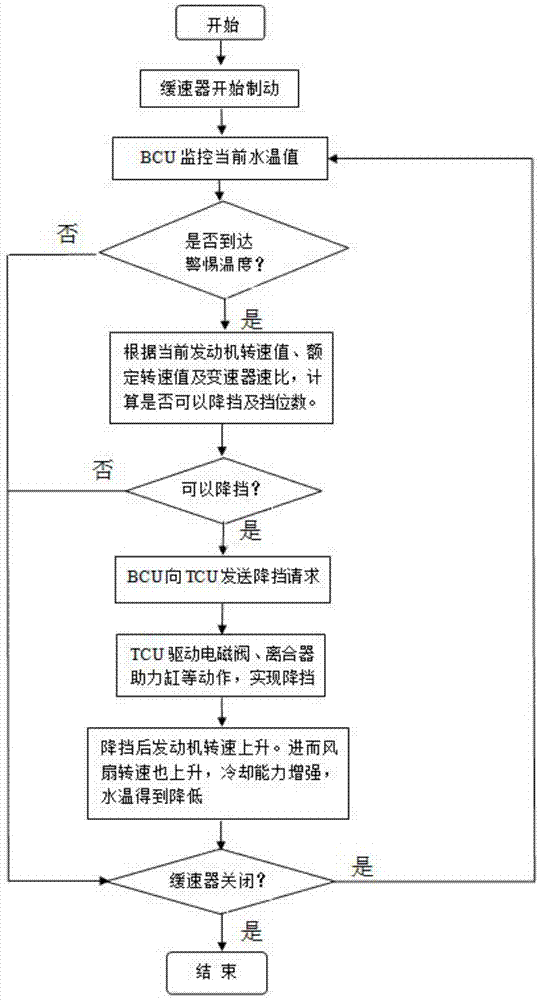

[0087] see figure 2 , the embodiment of the present invention provides a kind of control method of AMT heavy-duty special vehicle transfer gear shifting, comprises the following steps:

[0088] (1) After the engine ECU is powered on, the current coolant temperature t is collected through the water temperature sensor 1 (unit is ℃), and send it to the CAN bus through CAN information ET1, the sending cycle is 1000ms, the specific content is as follows.

[0089]

[0090] The body controller (BCU) can read the information of ET1 from the CAN line to know the current water temperature value.

[0091] (2) When the hydraulic retarder starts to work, it will send its status to the CAN bus through the message ERC1, and the sending cycle is 100ms.

[0092]

[0093] when a 1 =0, it means that the retarder does not play a braking role; if a 1 >0, indicating that the retarder is working for braking.

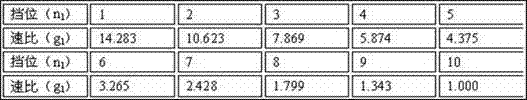

[0094] (3) BCU checks the content of ERC1, when it finds a 1 When >0, start q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com