Intelligent autorotation electric control screw

A technology for rotating motors and screws, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve problems such as difficulties, inconvenient, and difficult inspection by operators, and achieve strong work performance, improve work efficiency, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

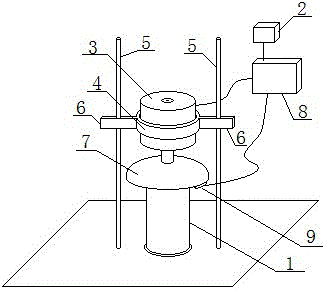

[0022] Such as figure 1 As shown, an intelligent self-rotating electric control screw designed by the present invention includes a screw body 1 and a screw cap 7 fixedly arranged on the top of the screw body 1; it also includes a fixed snap ring 4, at least one positioning rod 5, a control Module 8, and external power supply module 2, rotating motor 3, distance measuring sensor 9 connected with control module 8 respectively; Wherein, external power supply module 2 supplies power for rotating motor 3, distance measuring sensor 9 respectively through control module 8; The driving end of 3 is fixedly connected to the top of screw cap 7, and the axis of rotating motor 3 is collinear with the axis of screw body 1; the distance measuring sensor 9 is embedded in the lower surface of screw cap 7, and the distance measuring end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com