Automatic drill jumbo for tunnel and working method thereof

A rock drilling jumbo, automatic technology, applied in the direction of drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of dust and noise pollution, high labor intensity of workers, physical impact of workers, etc., to save construction costs , Excavation efficiency is fast, and the effect of ensuring construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

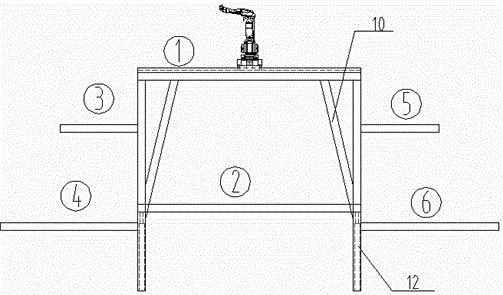

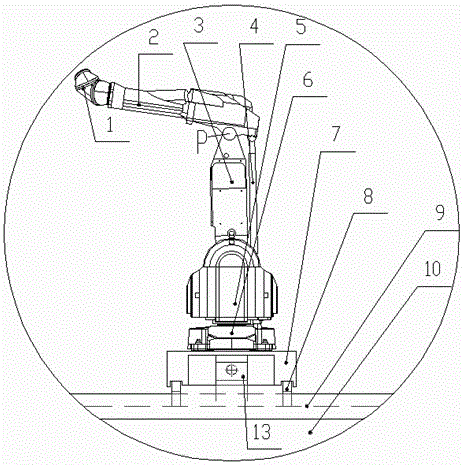

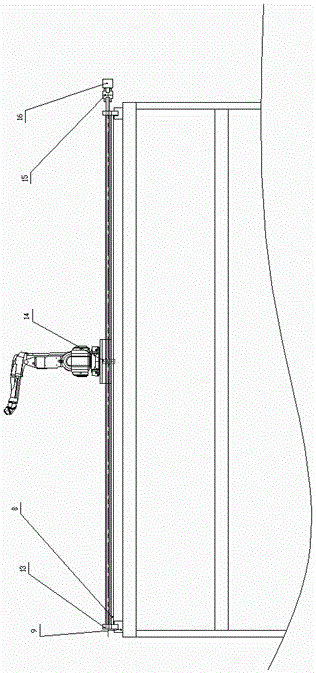

[0032] Such as Figure 1-3 As shown, this embodiment provides an automatic tunnel drilling jumbo. The main body of the jumbo is a trolley frame structure, and the trolley frame structure is welded by I-beams. It is a cubic frame or a rectangular frame The body can also be designed in other structural forms according to the needs of actual tunnel excavation conditions, which are not particularly limited here. In this embodiment, the frame structure of the trolley is provided with; six working surfaces: ①~⑥, and each working platform is provided with a working platform and a mechanical arm system ( figure 1 Only the robotic arm system and working platform on the worktable ① are shown in the figure). The layout of the six workbenches is as follows: one workbench is set on the top of the trolley frame structure, two workbenches are set on each side of the trolley frame structure, and one workbench is set in the middle area of the trolley frame structure, wherein, The worktable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com