Modularized rotational-flow air-flotation filtering device

A swirling air flotation and filtration device technology, which is applied in chemical instruments and methods, flotation water/sewage treatment, centrifugal separation water/sewage treatment, etc., can solve problems such as hindering the formation of swirling fluid, easy formation of bias flow, and pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

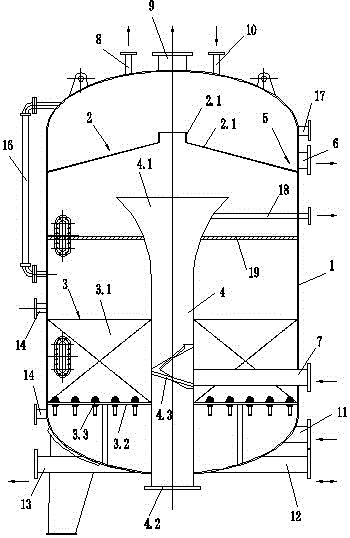

[0021] Embodiment 1: a modular cyclone air flotation filter device, comprising a cylinder 1, in which a slag collection tank 2 and a filter material layer 3 are arranged at intervals from top to bottom in the cylinder 1, and a cyclone is arranged in the center of the cylinder 1 4. The cyclone 4 is a cylindrical pipe body, the nozzle 4.1 at the upper end of the pipe body is directly below the slag collection tank 2, and the nozzle at the lower end protrudes from the lower head of the cylinder 1 as the sewage outlet 4.2, and the slag collection tank 2 is composed of a conical cylinder 2.1 with an inverted V-shaped cross section and a vertically upward scum pipe 2.2 set in the center of the conical cylinder 2.1. The side wall is sealed and connected, the upper surface of the wall of the slag collection tank 2 conical cylinder 2.1 and the cylinder wall of the cylinder 1 form a slag collection area 5, and the slag discharge port 6 begins to be formed on the side wall of the cylinder...

Embodiment 2

[0022] Embodiment 2: Referring to Embodiment 1, a swirl deflector 4.3 is arranged in the body of the cyclone 4, and the swirl deflector 4.3 is spirally inclined upward at an angle of 10-15°. The nozzle 4.1 at the upper end of the cyclone 4 pipe body is set as a bell mouth with a rising parabola outward.

Embodiment 3

[0023] Embodiment 3: with reference to embodiment 1 or 2, filter material intercepting net 19 is provided with above filter material layer 3.

[0024] The pressurized sewage is lifted by the pump and passes through the static mixer outside the device to mix the coagulant and flocculant, then merges into the dissolved air water, enters the cyclone in the tangential direction through the water inlet pipe 7, enters the cyclone 4, and passes through the cyclone diversion Plate 4.3 moves upward in a spiral separation process. During the spiral separation process, the sediment slides down along the inner wall of the cyclone and enters the sewage outlet. Then, the sludge discharge valve is automatically controlled by the PLC program according to the calculation of the amount of sludge entering the water for regular sludge discharge.

[0025] The rising dissolved air sewage condenses and coagulates the scum (oil) at the diffusion port on the upper part of the cyclone 4 by compressing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com