Automatic transmission mechanism for cylindrical workpieces

An automatic transfer, cylindrical technology, used in conveyors, transportation and packaging, etc., can solve the problems of low transfer efficiency, easy rolling of cylindrical workpieces, etc., and achieve the effects of accurate transfer, simple structure and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

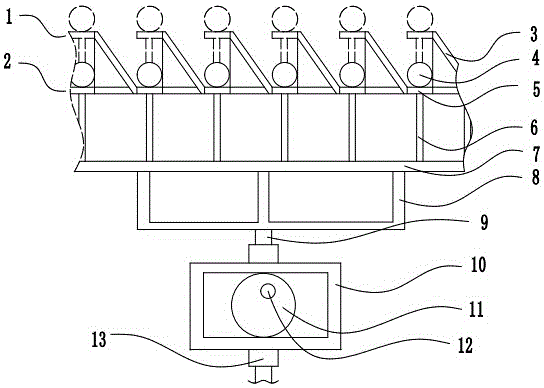

[0018] The reference signs in the drawings of the description include: first platform 1, second platform 2, slant plate 3, cylindrical workpiece 4, lifting plate 5, connecting rod 6, support plate 7, bracket 8, push rod 9, rectangular frame 10, cam 11, rotating shaft 12, guide sleeve 13.

[0019] Such as figure 1 As shown, the automatic transfer mechanism for cylindrical workpieces includes a first platform 1 and a second platform 2 with holes in corresponding positions in the vertical direction, the first platform 1 is located directly above the second platform 2, and the first platform 1 is clamped with the second platform 2 through the slanting plate 3 slanting downward. The shape of the lifting plate 5 matches the holes on the first platform 1 and the second platform 2 , and the lifting plate 5 can be fitted on the first platform 1 and the second platform 2 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com