Soft multiplayer oil tank

An oil tank and software technology, which is applied in the field of petrochemical gas storage and transportation devices, can solve the problems of insufficient pressure resistance, high construction cost and low anti-static property of soft oil tanks, and achieves improved safety, improved pressure resistance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

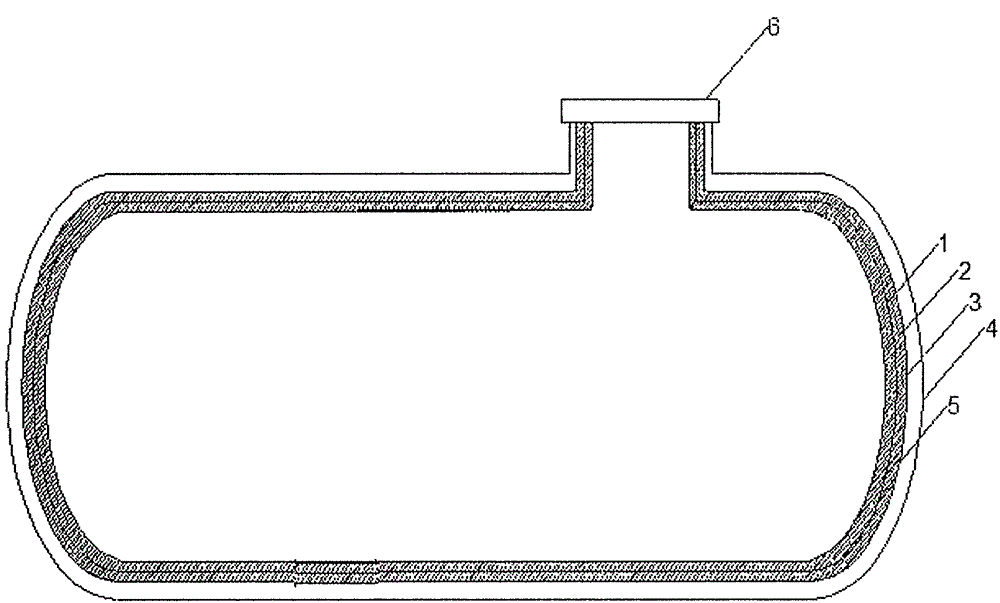

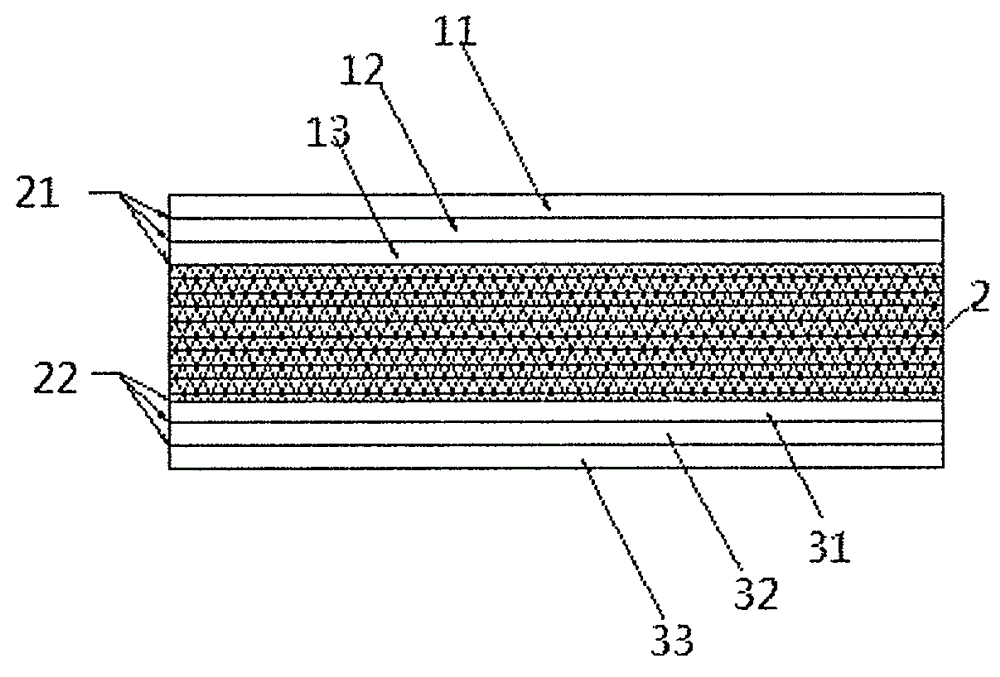

[0031] like figure 1 and figure 2 As shown, the soft multi-layer oil tank of the present invention can be directly placed in the existing steel oil tank 4, and the oil tank device includes a body, and the body sequentially includes an inner layer 1 from the inside to the outside (the thickness of the inner layer is 4mm ), the buffer layer 2 (the thickness of the buffer layer is 6mm) and the outer layer 3 (the thickness of the outer layer is 4mm); the inner layer includes the first static elimination layer 11, the first high barrier layer 12 and the first static elimination resistance Lamination layer 13; the outer layer includes a second static elimination layer 31, a second high barrier layer 32 and a second static elimination pressure-resistant layer 33; the buffer layer is provided with a leakage detection sensor 5; the leakage detection sensor 5 has A sensor that detects oil and triggers an alarm. The soft multi-layer oil tank of the present invention can be put in from...

Embodiment 2

[0033]The soft multi-layer oil tank of the present invention can be directly placed in the existing steel oil tank. The oil tank device includes a body, and the body includes an inner layer 1 (the thickness of the inner layer is 5mm), a buffer layer, and 2 (thickness of the buffer layer is 8mm) and outer layer 3 (thickness of the outer layer is 5mm). The inner layer includes a first static elimination layer, a first high barrier layer and a first static elimination voltage-resistant layer; the outer layer includes a second static elimination layer, a second high barrier layer and a second static elimination voltage-resistant layer; the The buffer layer is provided with a leak detection sensor 5; the leak detection sensor 5 has a sensor for detecting oil and triggering an alarm. The soft multilayer oil tank of the present invention can be put into from the entrance 6 of existing steel oil tank. The buffer layer 3 adopts reinforced 3D fabric. Both the first static elimination ...

Embodiment 3

[0035] The soft multi-layer oil tank of the present invention can be directly placed in the existing steel oil tank. The oil tank device includes a body, and the body includes an inner layer 1 (the thickness of the inner layer is 6mm), a buffer layer, and 2 (the thickness of the buffer layer is 10mm) and an outer layer 3 (the thickness of the outer layer is 6mm); the inner layer includes the first static elimination layer, the first high barrier layer and the first static elimination pressure-resistant layer; the outer layer includes The second static elimination layer, the second high barrier layer and the second static elimination pressure-resistant layer; the buffer layer 3 adopts reinforced 3D fabric. The buffer layer of the oil tank is provided with a leak detection sensor 5; the leak detection sensor 5 has a sensor for detecting oil and triggering an alarm. The soft multilayer oil tank of the present invention can be put into from the entrance 6 of existing steel oil tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com