Framework-type multi-door full water cooling vacuum device

A vacuum device, multi-door technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc. under vacuum/special atmosphere, can solve the problem of operating interface or operating distance limitation of movable doors, etc., to improve water cooling effect and vacuum effect, Easy to install, easy to disassemble and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

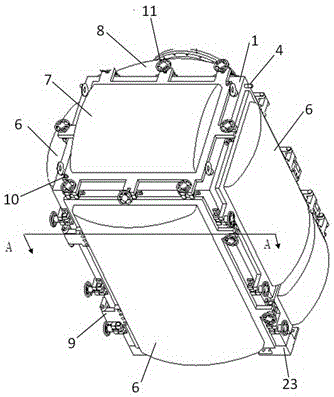

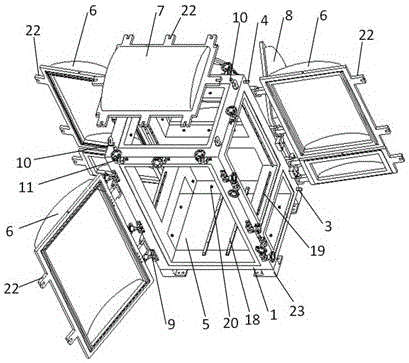

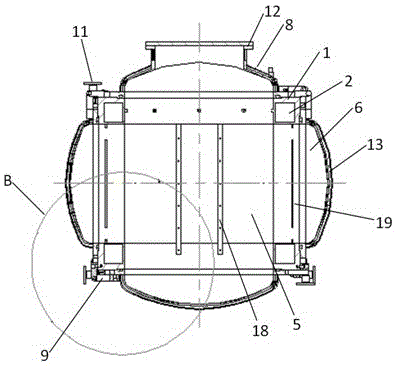

[0030] Such as Figure 1~4 As shown, a frame-type multi-door full water-cooled vacuum device includes a cuboid water-cooled frame 1 composed of hollow beams and longitudinal beams, a frame water jacket interlayer 2 formed in the beams and longitudinal beams of the water-cooled frame 1, and water inlets 3 and outlets. The water outlet 4 is connected, the bottom of the water-cooling frame 1 is fixed with a water-cooling base plate 5, the three sides of the water-cooling frame 1 are provided with a cylindrical hinge door 6 through a hinge 9, and the other side of the water-cooling frame 1 is provided with a vacuum pump door 8 through a screw. 8 is provided with a connecting flange 12 connected to the vacuum pump, and the top of the water-cooling frame 1 is provided with a direct pin top cover 7, and the free end of the cylindrical hinged door 6 and around the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com