Energy-saving vehicle brake device

A vehicle braking and energy-saving technology, applied in the direction of brakes, braking components, vehicle components, etc., can solve the problems of shortening the service life of tires and road surfaces, braking tires and road surface damage, waste of heat of wheels, etc., and achieves the design structure. Simple and reasonable, prolong the service life, avoid the effect of side slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

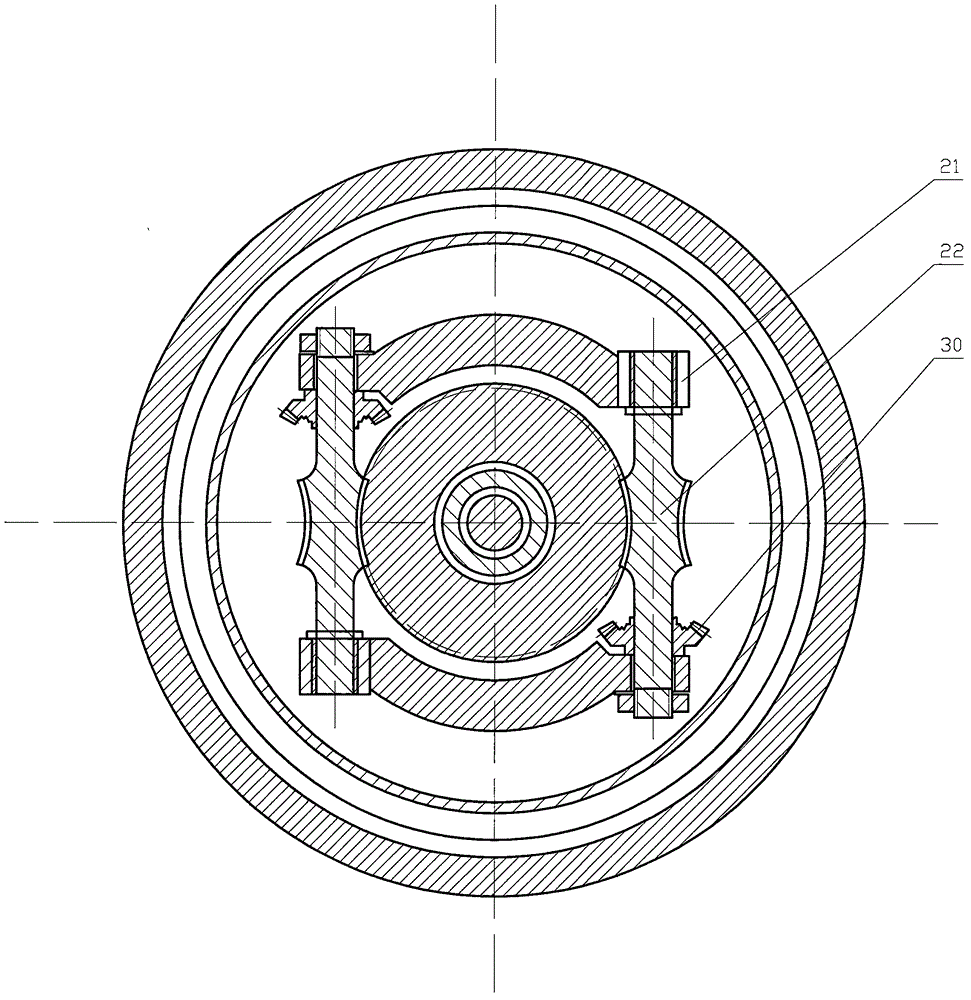

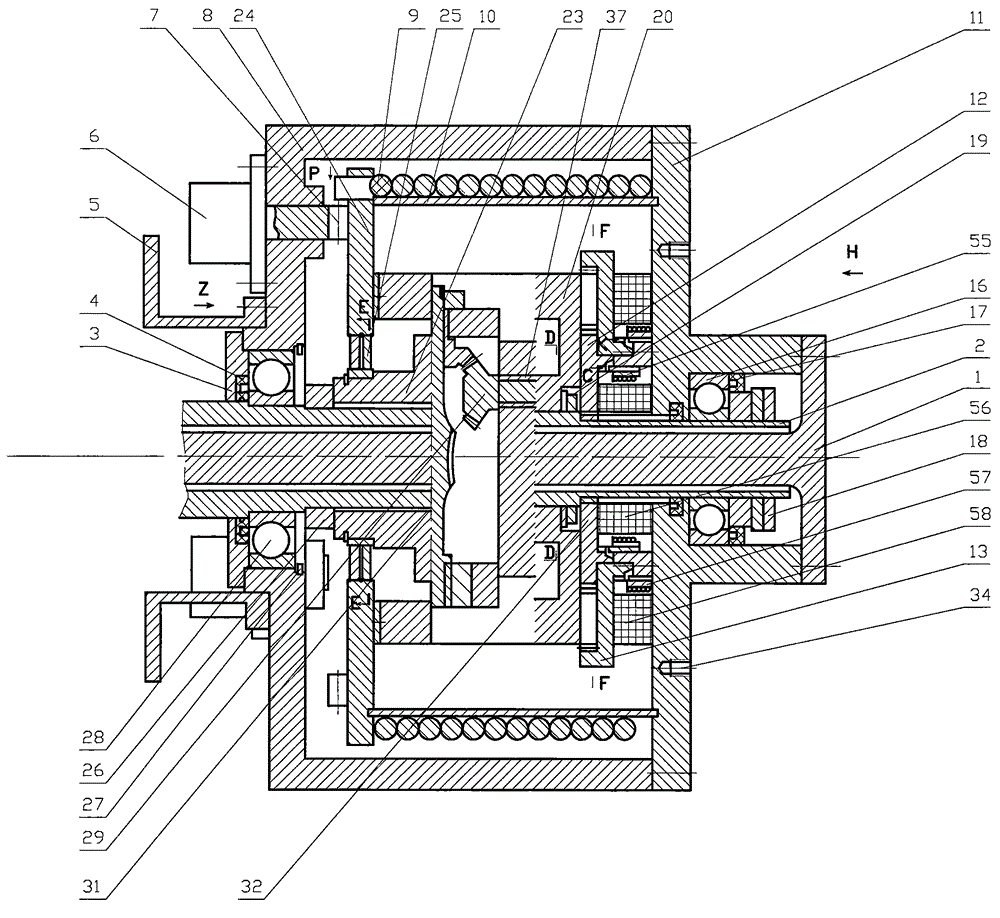

[0042] Embodiment 1 (being applicable to automobile etc.)

[0043] Such as figure 1 As shown in -13, the energy-saving vehicle braking device includes a power input and output part assembled on the axle shaft sleeve 2, a deceleration part, a torsion spring part, a housing, a bearing and ancillary parts. The housing consists of a front cover 11 and rear cover 8 are formed and fixed by bolts, the outer side of front cover 11 is provided with a bolt hole 34 for connecting the tire hub, the outside of the half shaft 1 is provided with a half shaft sleeve 2, and the front end of the half shaft 1 is disc-shaped and front. Cover 11 is connected and fixed. The front cover 11 and the rear cover 8 are respectively supported on the half-shaft casing by the front and rear bearings 16 and 28. Oil seals 17 are provided on the inside and outside of the front bearing, and are locked and positioned by lock nuts 18. An oil seal is provided on the outside of the rear bearing 28. 3 and sealing ...

Embodiment 2

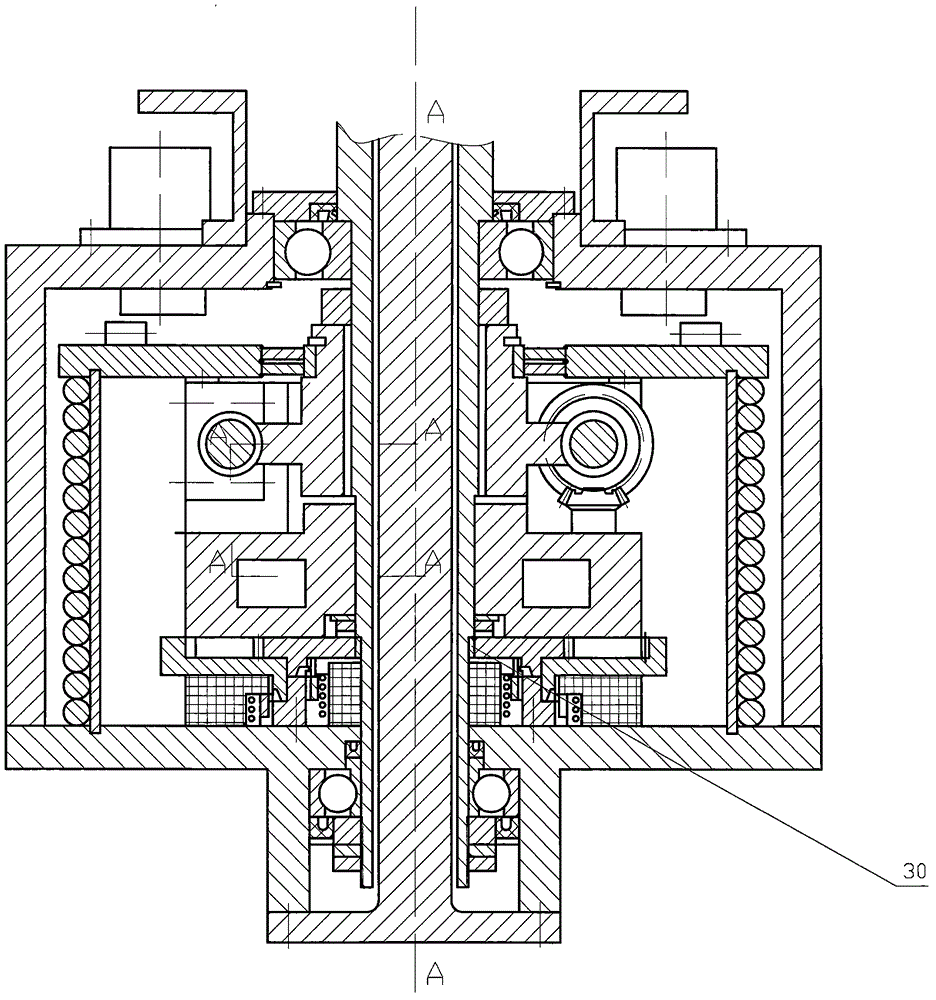

[0052] Embodiment 2 (applicable to trains, etc.) such as Figure 12 The energy-saving vehicle braking device of Fig. 17 includes the power input and output part assembled on the axle shaft 63, the speed reducer part, the torsion spring part, the housing, the bearing and the accessory part are different from the automobile in that the semi-axle sleeve is eliminated.

[0053] The power input and output part and the reducer part housing, bearing and accessory parts are basically the same as those in Embodiment 1, and will not be described in detail.

[0054] There are two sets of elastic force input and output parts, including the elastic force input and output part for forward braking and the elastic force input and output part for reverse braking. Direction opposite overrunning clutch 48, the spring knot hand 38 that is driven by overrunning clutch, the outer periphery of described spring knot hand 38 is provided with a groove, and described torsion spring part is the torsion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com