Front bus engine mounting system

A technology for engine mounts and engines, applied in power plants, vehicle parts, jet propulsion devices, etc., can solve the problems of different structures of the left and right brackets, poor shock absorption effect, and influence on transmission efficiency, so as to avoid assembly difficulties and errors , Improve assembly efficiency and shock absorption effect, improve the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

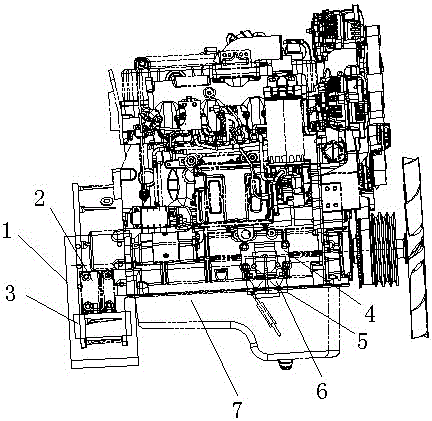

[0040] Such as Figure 1-Figure 3A front passenger car engine suspension system shown includes a left engine front bracket and a right engine front bracket 2 symmetrically arranged on the left and right sides of the front end of the engine 7, and is used to install the left engine front bracket and the right engine front bracket 2 on the The engine front bracket 1 on the vehicle body chassis, the left engine front suspension cushion arranged between the left engine front bracket and the left end of the engine front bracket 1, the left engine front suspension cushion arranged between the right engine front bracket 2 and the right end of the engine front bracket 1 The right engine front suspension cushion 3 which is spaced and opposite to the left engine front suspension cushion, the left engine rear support and the right engine rear support 4 which are symmetrically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com