A control method for integrated printing and embossing of rotary screen gravure printing

A technology for printing embossing and control methods, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of single overprinting method and inability to combine, and achieve the effect of simplifying mechanical structure, improving stability, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

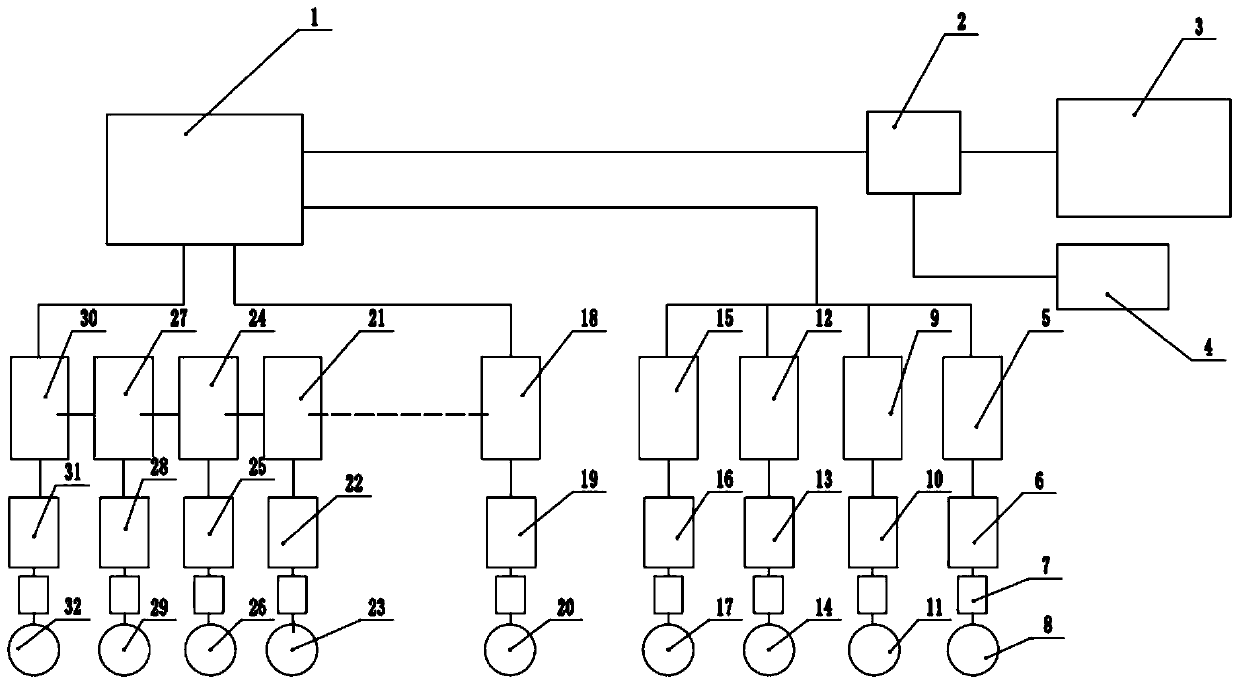

[0029] The present invention relates to a rotary screen gravure integrated printing and embossing control method based on the rotary screen gravure integrated printing embossing control system, such as figure 1 As shown, the specific structure of the rotary screen gravure integrated printing and embossing control system is as follows: the motion controller 1 is respectively connected to the PLC programmable logic controller 3 and the HMI touch screen 4 through the Ethernet switch 2, and the motion controller 1 is also connected through the control Gravure servo driver 30, rotary screen servo driver 27, water-cooled servo driver 24, embossing servo driver 21 and delivery servo driver 18 to control plate roller shaft 32, rotary screen shaft 29, water-cooling shaft 26, embossing shaft 23, feeding and pulling servo driver 18 Axis 20, gravure serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com