Stranded Cable Wire Heat Shrinker

A multi-strand cable and heat shrinking machine technology, which is applied in the field of multi-strand cable wire heat shrinking equipment and multi-strand cable wire heat shrinking machine, can solve the problems that the processing quality cannot be guaranteed, the heating is uneven, and the quality is difficult to control. Avoid sudden high temperature heating and sudden cooling, heat shrinkage quality is stable, and there are no wrinkles and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

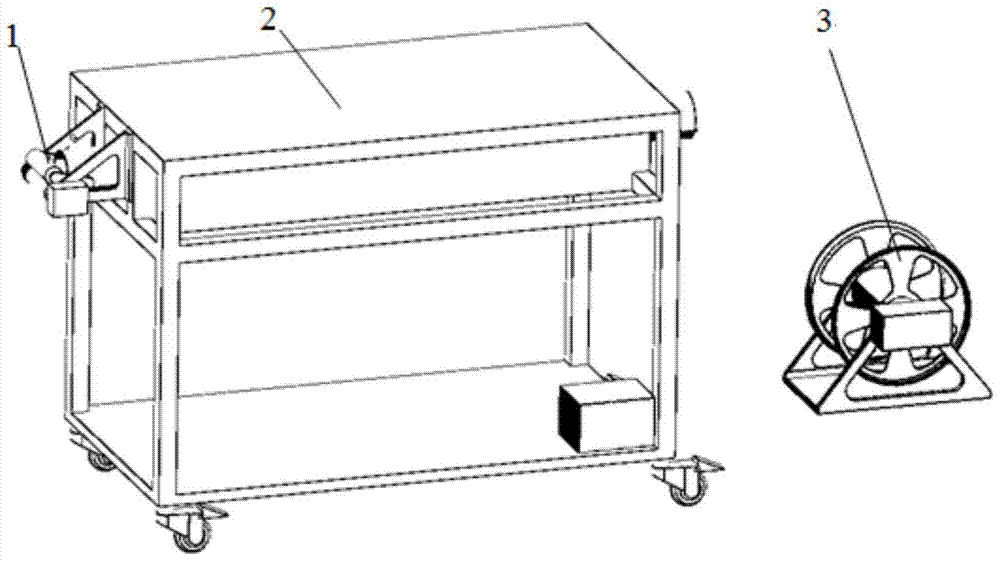

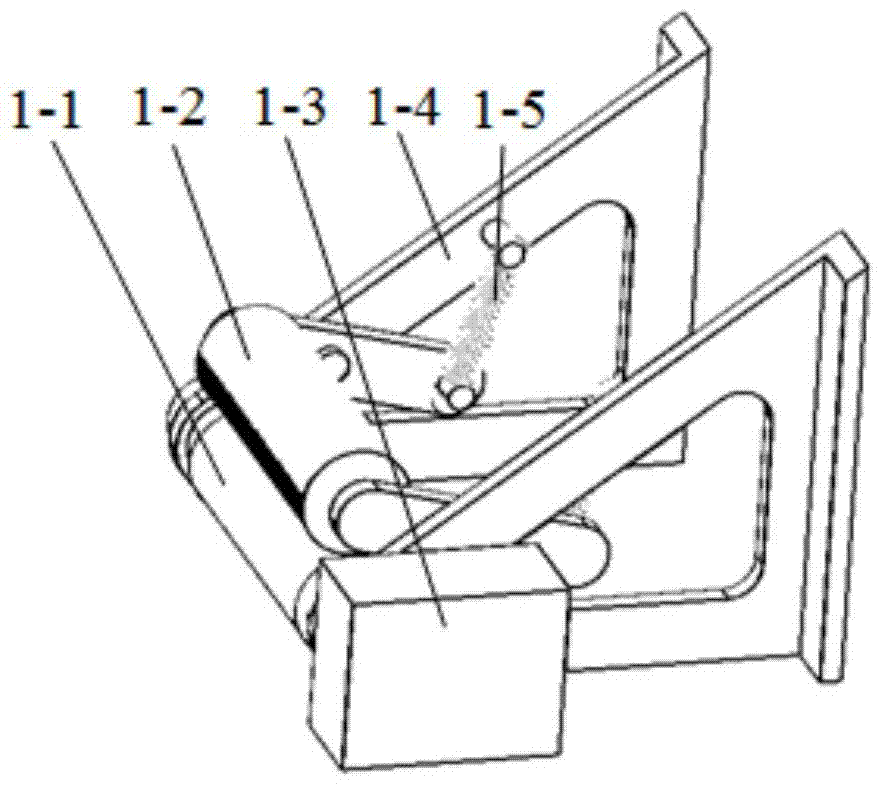

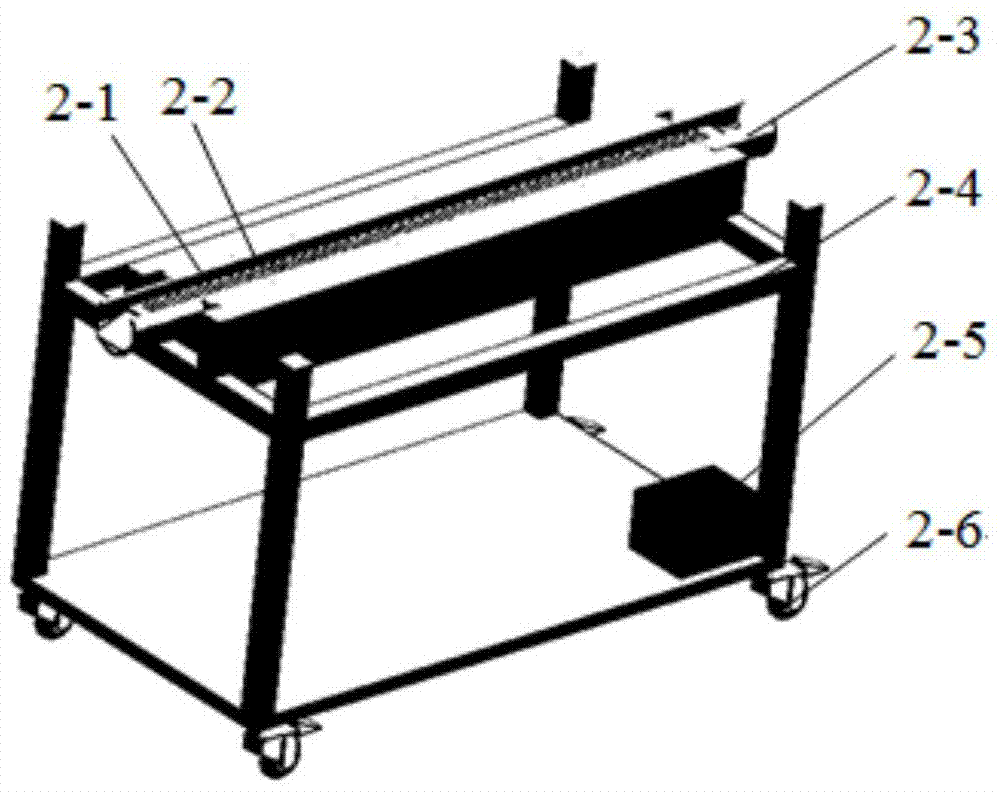

[0024] The multi-strand cable wire heat shrinking machine provided by the invention includes three parts: a wire feeder, a 360° heat shrinker and a wire take-up device. The wire feeder consists of two cylindrical pressure cylinders with identical appearance, a power source, a bracket and a set of springs. The two pressure cylinders are fixed on the bracket, and the energy storage of the spring makes the pressure cylinders tend to be close to each other, and the power source can drive one of the pressure cylinders to rotate at a set speed at a constant speed. The 360° heat shrinker is composed of several annular heaters, a cable support plate, a temperature controller, two wind hoods, a frame and universal wheels. The shape of the ring heater is a ring, and the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com