Low-breakage sunflower threshing machine capable of automatically adjusting de-seeding gaps

A sunflower, self-regulating technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of complex structure of threshing machinery, easy to break sunflower discs, low efficiency, etc., and achieve small damage rate, simple structure, and energy saving The effect of the cleaning device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

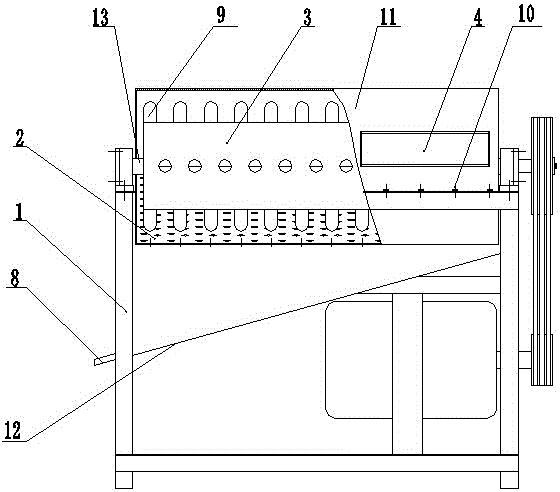

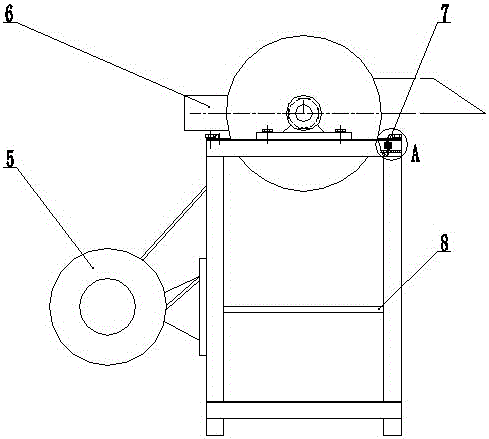

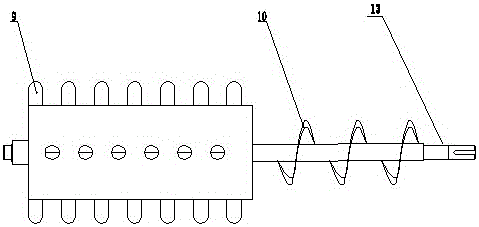

[0018] A self-adjusting low-breaking sunflower thresher for deseed clearance, comprising a frame 1, a motor 5 fixedly arranged under the side of the frame to provide power for thresher threshing, and a threshing cylinder 3 fixed on the frame 1. The threshing drum 3 includes a roller 13 that is matched with the bearing seats at both ends of the frame 1, a machine cover 11 arranged on the top of the roller 13, and a punching screen 2 positioned below the roller 13. The outer circumference of one end of the roller 13 is provided with a The spiral blade 10 is provided with hobbing teeth 9 on the outer peripheral surface of the other end, and a feeding port 4 for feeding sunflowers is provided on the side close to the spiral blade 10 on the machine cover 11, and a discharge and cleaning device is provided near the side of the hobbing teeth 9. The waste port 6 of the sunflower disk, the bottom of the punching screen 2 is connected with the frame 1 through the elastic element 7, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com