Automatic protecting harvesting machine

An automatic protection, harvester technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of increased manual labor and reduced production efficiency, to improve work efficiency, avoid stuck, reduce manual labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

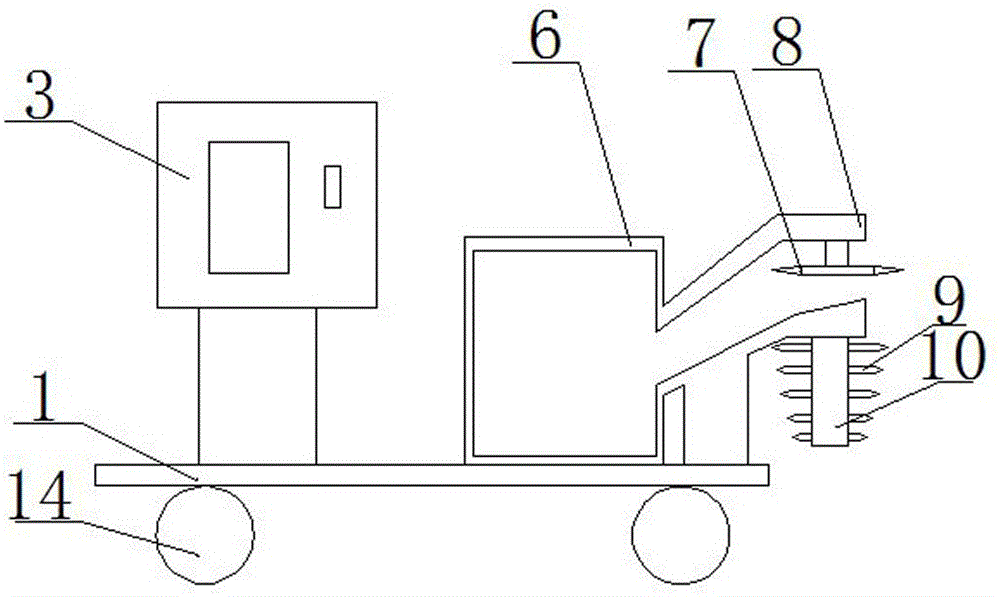

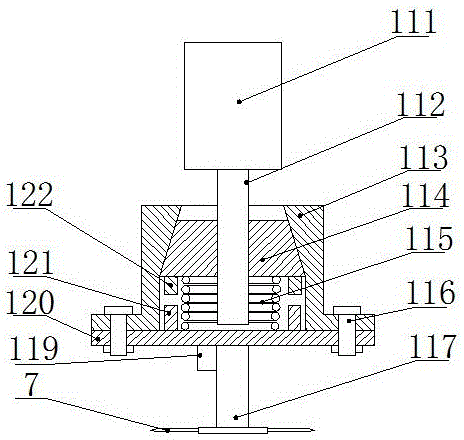

[0016] Figure 1-2 Shown is a harvester with automatic protection provided by the present invention, including: vehicle frame 1, driver's cab 3, storage box 6, harvesting cutter 7, harvesting port 8, cutter 9, rotating cylinder 10, road wheels 14, Motor 111, motor output shaft 112, housing 113, tapered column 114, spring 115, mounting cover 120, bolt 116, connecting shaft 117 of harvesting tool, torque sensor 119, electromagnet 121 and iron block 122. Described vehicle frame 1 is provided with driver's cab 3 and harvesting device, and its lower end is provided with traveling wheel 14; Described harvesting device comprises harvesting port 8, is provided with harvesting cutter 7 and motor 111 on the harvesting port 8, the connecting shaft of harvesting cutter 117 is provided with a torque sensor 119, and a protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com