Fuel-efficient engine oil composition

A composition and oil technology, applied in the directions of lubricating compositions, petroleum industry, base materials, etc., can solve the problems of deteriorating fuel-saving effect, increasing friction in surrounding lubricating areas, lack of oil film strength, etc., and achieving excellent fuel-saving performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

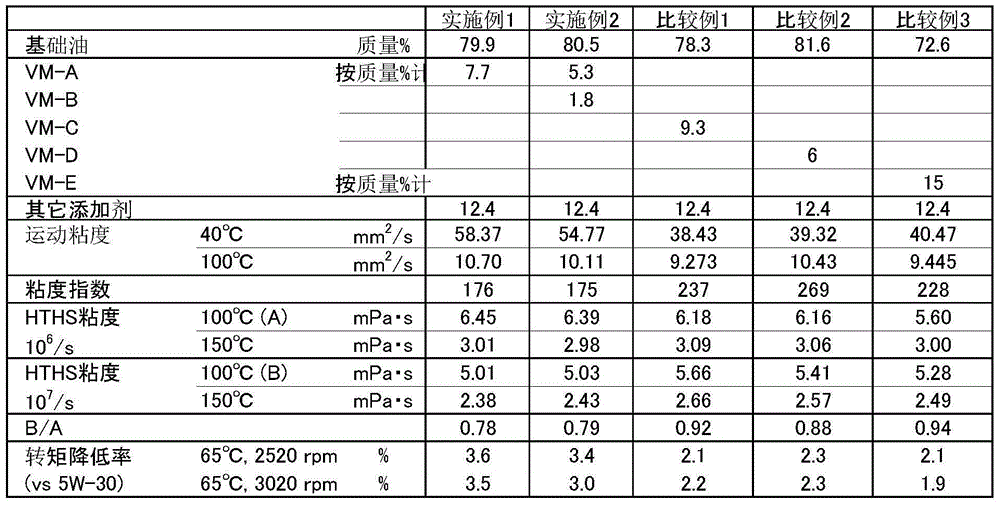

[0117] (Examples 1 and 2, Comparative Examples 1 to 3)

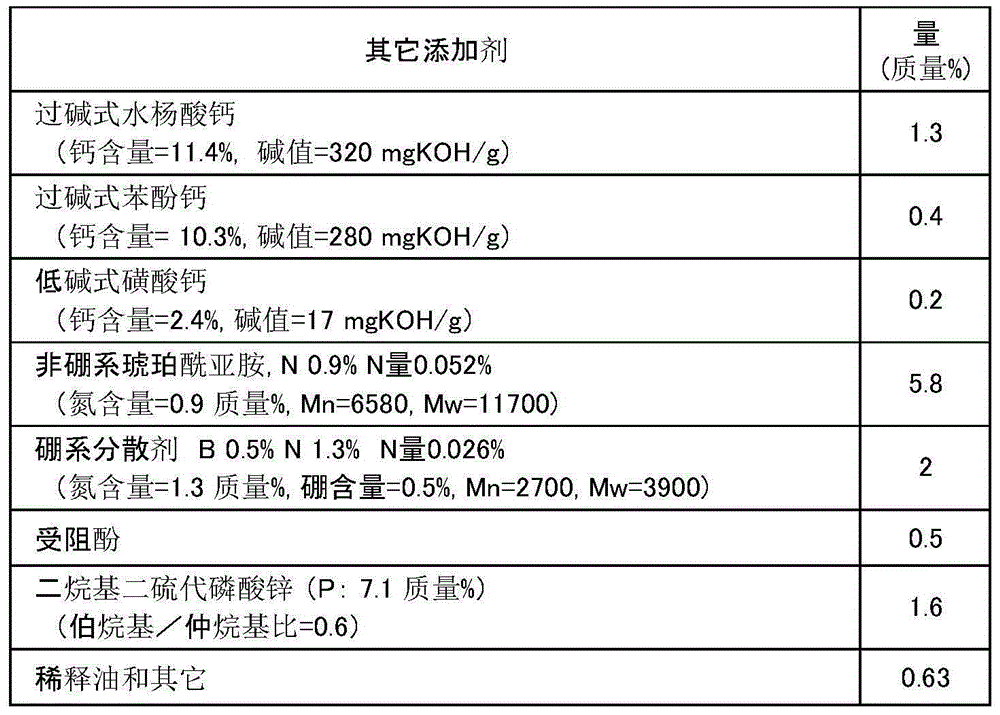

[0118] Various engine oil compositions were prepared by blending a viscosity index improver and other additives in the amounts shown in Table 2 using base oils having properties shown in Table 1. The properties of other additives are shown in Table 3.

[0119] Table 2 shows the composition and properties of each engine oil and the evaluation results.

[0120] From the results shown in Table 2, it is clear that the engine oils of Examples 1 and 2, in which the B / A ratios were 0.78 and 0.79, respectively, can be expected to be excellent in fuel economy because the oils evaluated by the idling test compared with 5W-30 The torque reduction rate is 3.0-3.6%. Meanwhile, the engine oils of Comparative Examples 1 to 3 in which the B / A ratio is 0.88 to 0.94 have a torque reduction ratio of 1.9 to 2.3% as evaluated by the idling test compared with 5W-30, and thus cannot be obtained as obtained in Examples 1 and 2. The excellent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com