Cooling device and cooling method for a rotor-integrated coupling for hybrid modules

A technology for hybrid power modules and cooling equipment, applied in hybrid power vehicles, fluid-driven clutches, mechanically driven clutches, etc., can solve the problems of reducing the quality of clutch operating characteristics or clutch functions, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

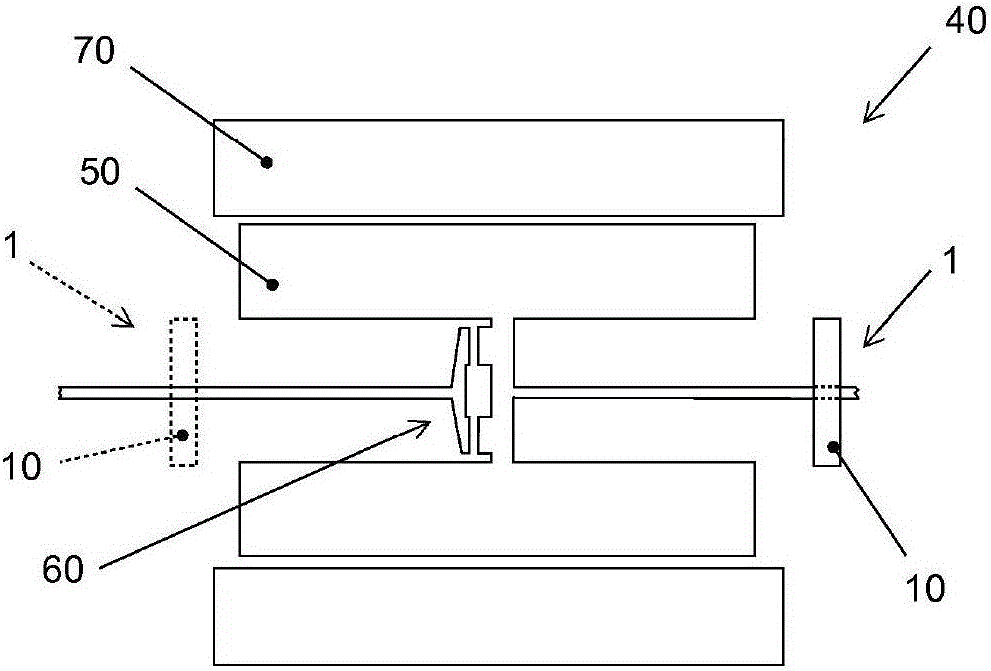

[0027] exist figure 1 , the cooling device 1 has a fluid transport device 10 . The hybrid module 40 has a stator 70 and a rotor 50 in which the clutch 60 is integrated. The fluid transport device 10 is arranged on the rotor 50 on one side of the clutch 60 , for example on the transmission side. The dashed line shows an alternative in which the fluid transport device 10 is arranged on the other side of the clutch 60 , for example on the side of the internal combustion engine. Preferably, the fluid transport device 10 is connected in a rotationally fixed manner to the rotor 50 . In this alternative arrangement (dashed line), the fluid transport device is connected in a rotationally fixed manner to a shaft driven by the internal combustion engine.

[0028] In operation of the invention, fluid is transported in the direction of the clutch 60 by means of the fluid transport device 10 by suctioning fluid from the area of the clutch 60 so that new, cooler fluid flows from a gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com