Connector

A technology of connectors and plug-in connectors, which is applied in the direction of connection, parts of connection devices, electrical components, etc., to achieve a good fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

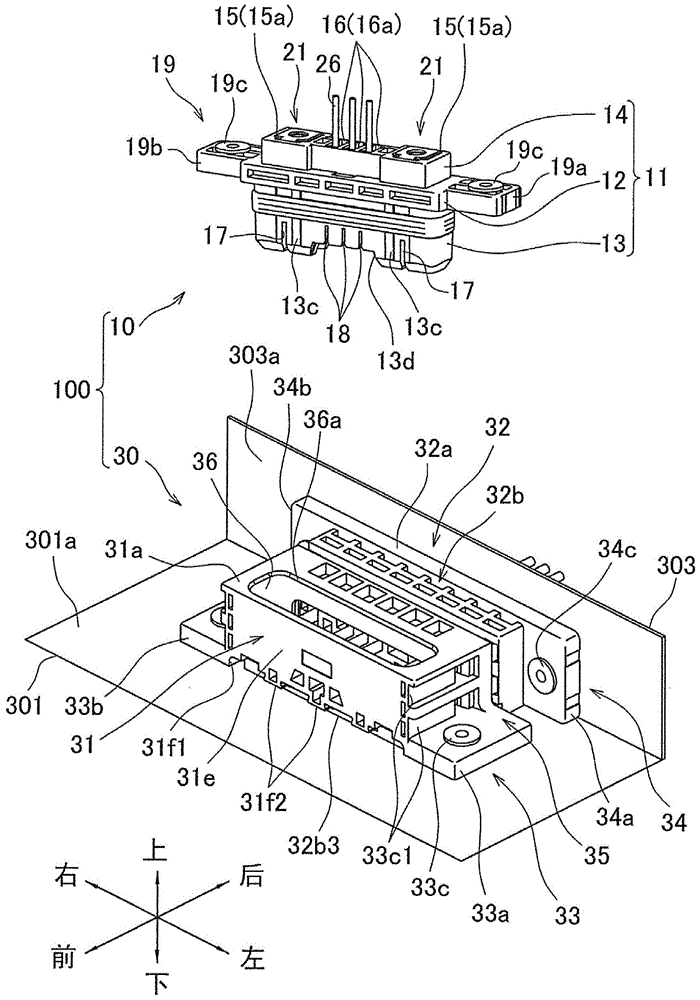

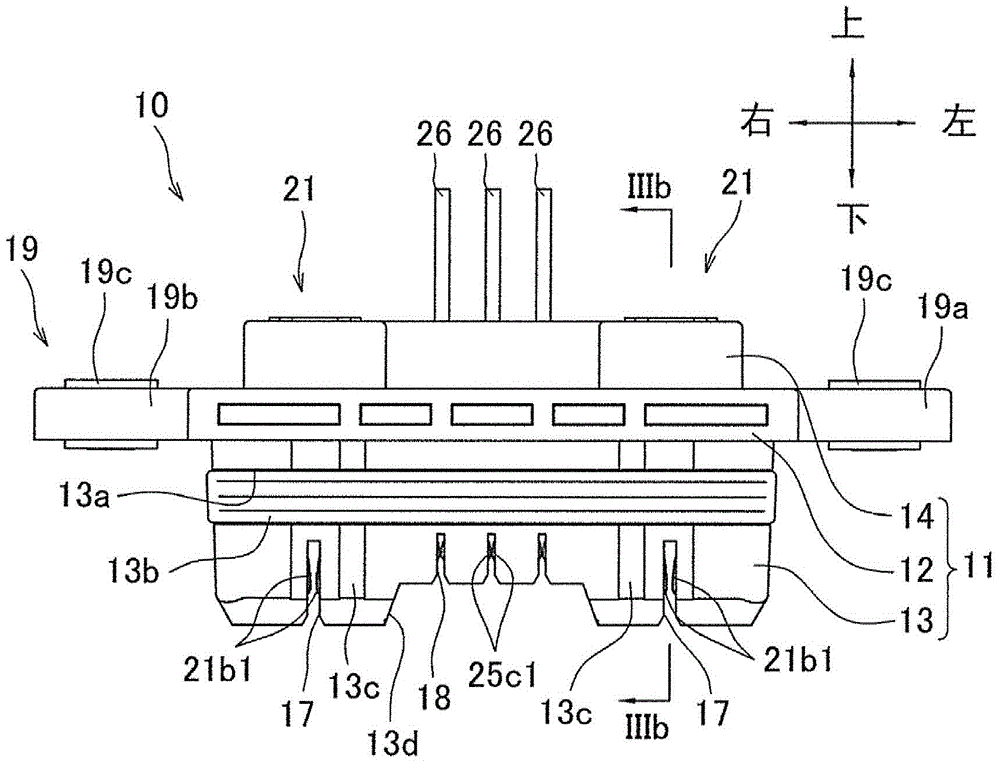

[0026] Preferred embodiments of the present invention will be described below with reference to the drawings.

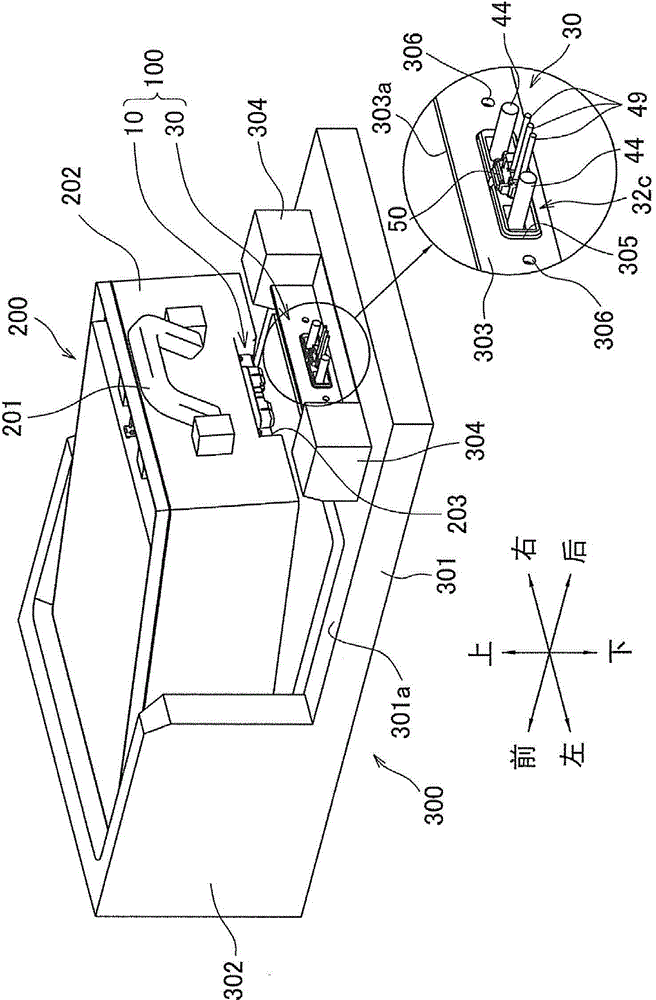

[0027] Such as figure 1 As shown, the connector 100 according to this embodiment is composed of a plug connector 10 and a base connector 30, the plug connector 10 is installed on the battery unit 200, and the base connector 30 is installed on the power supply device on which the battery unit 200 is installed. The installation part 300.

[0028] Here, the definition of the direction in this embodiment is demonstrated. Such as figure 1 As shown, the direction (first direction) perpendicular to the upper surface 301a (first mounting surface) of the support plate 301 of the mounting part 300, that is, the direction from the support plate 301 toward the connector 1 and the opposite direction are respectively defined as the upper direction. and below, the direction (second direction) perpendicular to the front surface 303a (second mounting surface) of the mounting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com