Magnetic coupling inductor of interleaving parallel converter and magnetic core

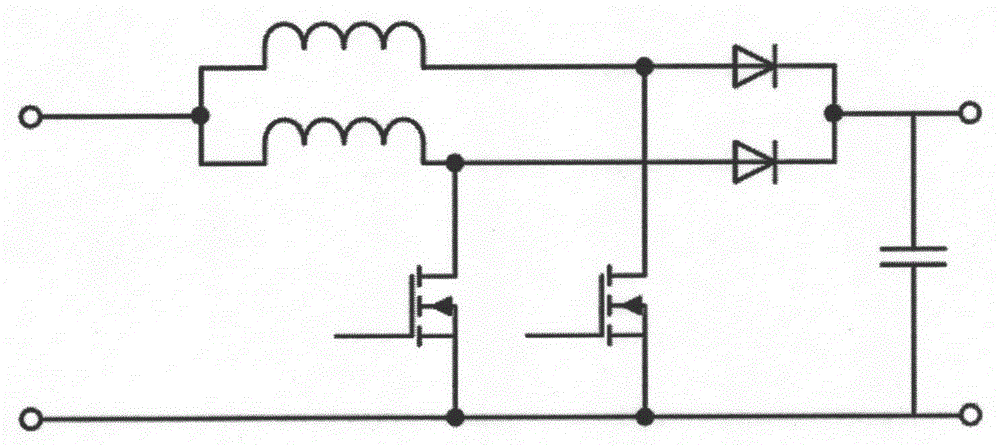

A technology of magnetic core and coupling degree, applied in the direction of transformer/inductor magnetic core, transformer/inductor coil/winding/connection, electrical components, etc., can solve the problems of difficult optimization of magnetic core structure and inflexible adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

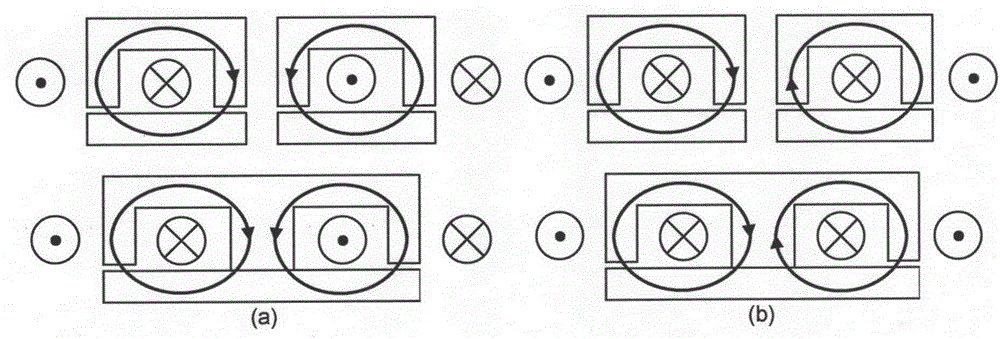

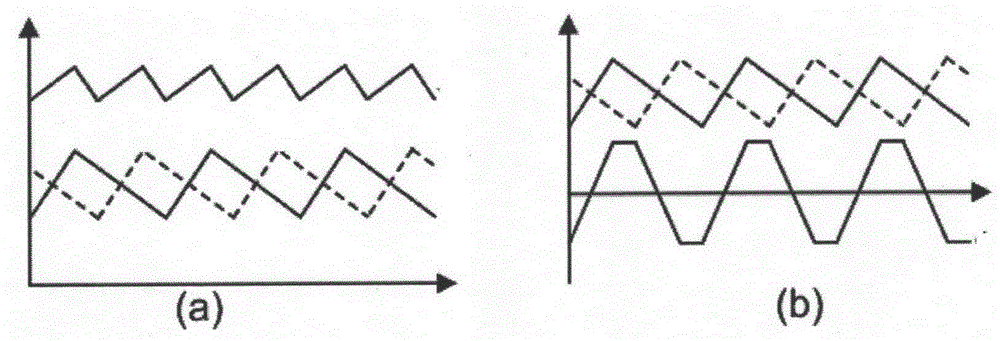

Embodiment 1

[0029] like Figure 5 As shown, the magnetically coupled inductor 100 in this embodiment includes two coils 105 and a magnetic core. The magnetic core includes an upper plate 101 , a lower plate 102 , two side column magnetic cores 103 and a central column magnetic core 104 . Wherein, the upper plate 101 and the lower plate 102 can be an independent magnetic core with the first magnetic permeability, or a magnetic core with the equivalent first magnetic permeability spliced by multiple magnetic cores, which is used to splice the upper and lower plates The magnetic permeability of the multiple magnetic cores can be the same or different; the two side column magnetic cores 103 can be an independent magnetic core with the second magnetic permeability, or a plurality of magnetic cores spliced together to have the equivalent first magnetic core. The magnetic core of two magnetic permeability, the magnetic permeability of a plurality of magnetic cores that are used for splicing...

Embodiment 2

[0033] refer to Image 6, the magnetically coupled inductor 200 in this embodiment includes two coils 205 and a magnetic core. The magnetic core includes an upper plate 201 , a lower plate 202 , two side column magnetic cores 203 and a central column magnetic core 204 . Wherein, upper plate 201 is made up of the left magnetic core 206 of the left side magnetic core 206 of the upper end 205 of center column magnetic core 204,205 and the right side magnetic core 207 of 205; flush and of the same depth. Lower plate 202 is made up of the lower end 208 of center column magnetic core 204, the left side magnetic core 209 of 208 and the right side magnetic core 210 of 208; , with the same depth. The magnetic cores 206, 207, 209 and 210 have the same size, and can be an independent magnetic core with the first magnetic permeability, or a magnetic core with the equivalent first magnetic permeability formed by splicing multiple magnetic cores, The magnetic permeability of a plurality...

Embodiment 3

[0036] refer to Figure 7 , in this embodiment the magnetically coupled inductor 300 includes two coils 305 and a magnetic core. The magnetic core includes an upper plate 301 , a lower plate 302 , two side column magnetic cores 303 and a central column magnetic core 304 . Wherein, the upper plate 301 is composed of the magnetic core 306 and the upper parts 307 and 308 of the side column magnetic core 303; the upper end of the magnetic core 306 is flush with the upper end of the side column magnetic core 303 and has the same depth. The lower plate 302 is jointly composed of a magnetic core 309 and lower parts 310 and 311 of the side post magnetic core 303 ; the magnetic core 309 is flush with the lower end of the side post magnetic core 303 and has the same depth. The magnetic cores 306 and 309 can be an independent magnetic core with a first magnetic permeability, or a magnetic core with an equivalent first magnetic permeability spliced by multiple magnetic cores, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com