Testing device for achieving plane strain state in large-deformation range and data processing method

A plane strain and testing device technology, applied in the direction of electrical digital data processing, special data processing applications, using stable tension/pressure testing material strength, etc., can solve problems such as difficulty in adapting to actual needs, small deformation range, etc., and achieve structural Simple, data-accurate, and performance-reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

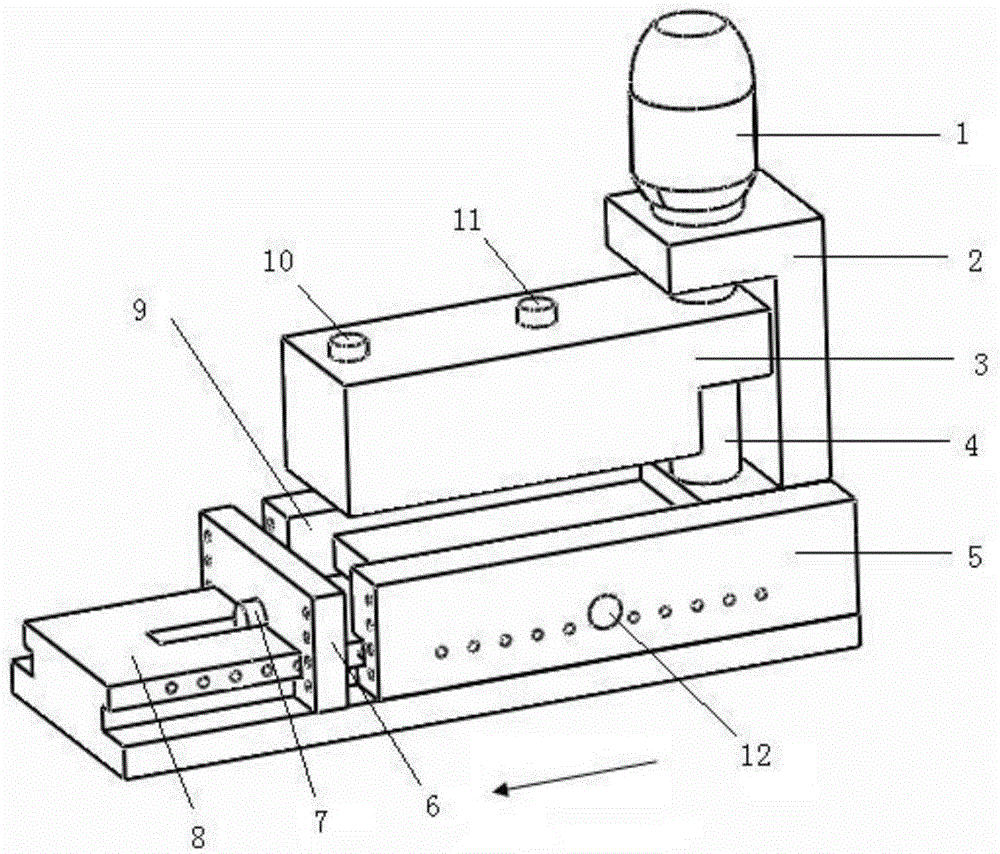

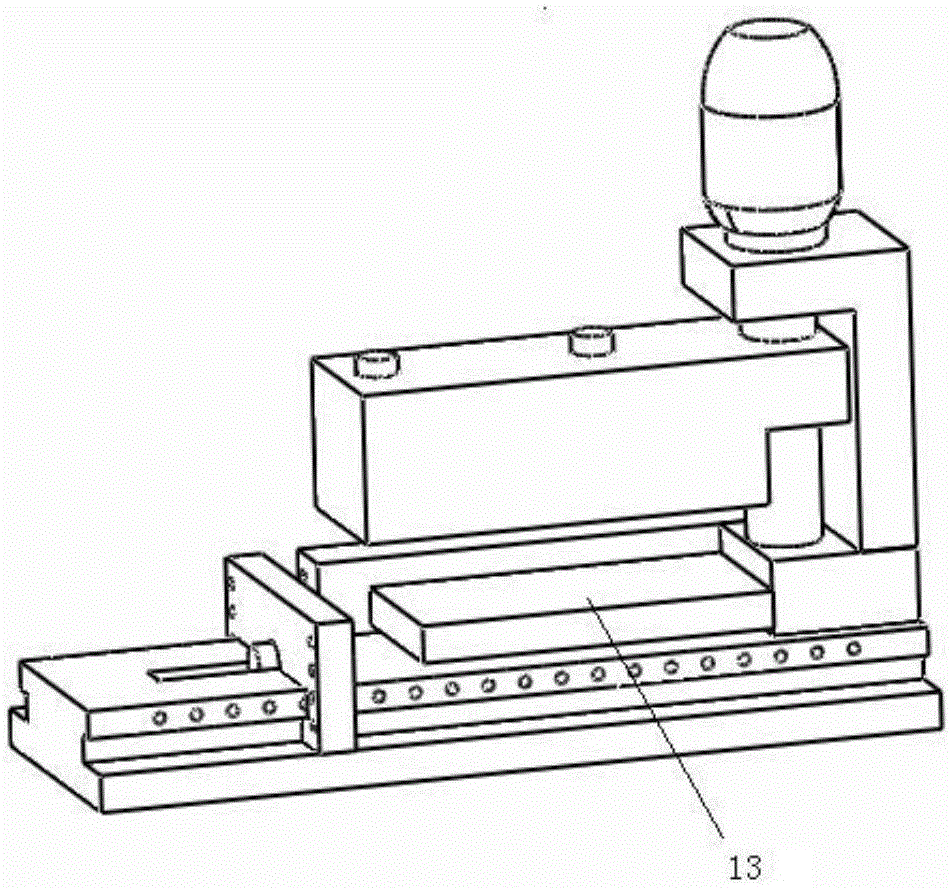

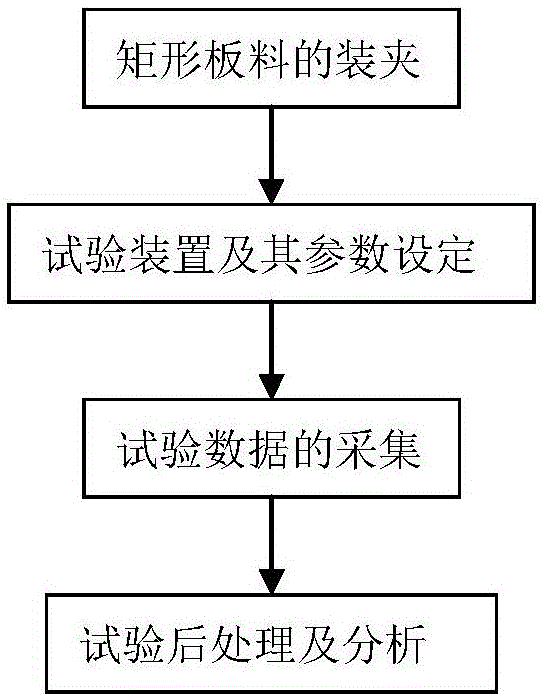

[0037] (1) see figure 1 , figure 2 , a test device for realizing a plane strain state in a large deformation range, which includes a motor 1, a bracket 2, a pressure plate 3, a screw 4, a baffle 5, a stopper 6, a laser ranging sensor 7, a workbench 8, and a baffle 9. Laser distance measuring sensor 10, pressure sensor 11, pressure sensor 12 and measured sheet 13. The position connection relationship between them is: the motor 1 is installed on the bracket 2 and connected with the pressure plate 3 and the lead screw 4, the laser distance measuring sensor 10 and the pressure sensor 11 are installed on the pressure plate 3, the baffle plate 5 and the baffle plate 9 are arranged in the working The two sides of the platform 8 are connected with the workbench 8 and the block 6 by screws; the laser distance sensor 7 is provided in the middle of the block 6, and the pressure sensor 12 is provided in the middle of the baffle 5; the measured sheet 13 is located on the baffle 5, On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com