Ore dressing deep trough slurry enclosed sampler

A technology of sampler and slurry, applied in the direction of sampling device, etc., can solve the problem of inaccurate sampling and achieve the effect of accurate sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

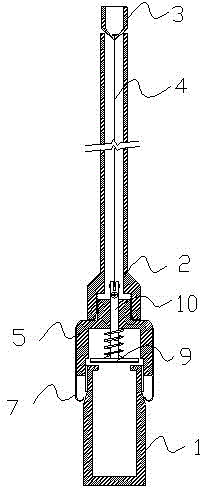

[0020] Such as figure 1 , 2 , 3, 4, and 5, Embodiment 1 of the present invention: a kind of ore dressing deep groove slurry airtight sampler, it comprises slurry bucket 1, the sampling rod 2 that links to each other with slurry bucket, is used for plugging slurry bucket 1 and a stretching device connected to the plugging device, the sampling rod 2 is connected to the plugging device, the slurry tank 1 is provided with a window, and a transparent plate is fixedly connected in the window.

Embodiment 2

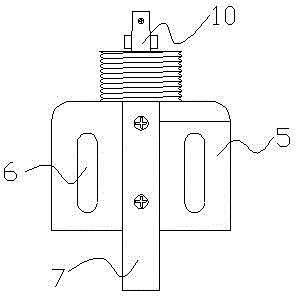

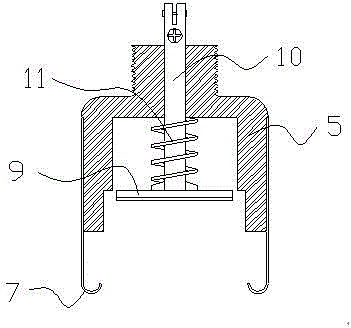

[0021] Such as figure 1 , 2 , 3, 4, and 5, Embodiment 2 of the present invention: a kind of ore dressing deep tank slurry airtight sampler, which includes a slurry bucket 1, a sampling rod 2 connected to the slurry bucket, used to block the slurry bucket The plugging device of 1 and the stretching device connected with the plugging device, the sampling rod 2 is connected with the plugging device, the slurry tank 1 is provided with a window, the window is fixedly connected with a transparent plate, and the sampling rod 2 is provided with The through hole, the stretching device includes a pull rod 3, the pull rod 3 is adapted to the inner diameter of the through hole, one end of the pull rod 3 is fixedly connected with a steel wire 4, the steel wire 4 passes through the through hole and is connected to the blocking device, and the blocking device includes a housing 5 , the periphery of the outer surface of the housing 5 is provided with a number of slurry inlet holes 6, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com