Bearing detecting device

A technology for bearing detection and one-way bearings, which is applied in measuring devices, mechanical bearing testing, power measurement, etc., can solve problems such as detection data distortion, damage, and internal structure deformation of bearings, and achieve the effect of real data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

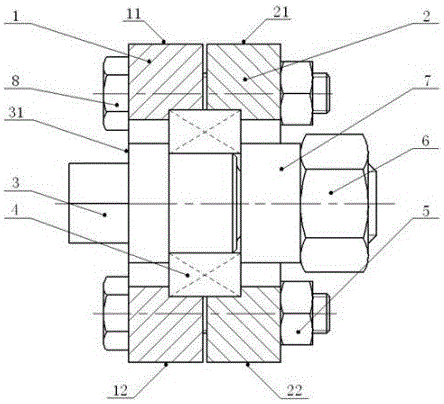

[0009] The present invention will be further explained below in conjunction with the drawings in the specification:

[0010] A bearing detection device for measuring the reverse torque of a one-way bearing 4, comprising: a left side clamp body 1, a right side clamp body 2 and a spindle 3; the left side clamp body 1 and the right side clamp body 2 The structure is the same, a number of threaded holes are evenly opened, and the inner holes of the left clamp body 1 and the right clamp body 2 are in clearance fit with the outer circular surface of the one-way bearing 4, and the left clamp The bolts in the threaded holes of the concrete 1 and the right clamp body 2 are fastened so that the left clamp body 1 and the right clamp body 2 are combined, and the outer ring end face of the one-way bearing 4 is fixed, specifically The hexagonal head bolt 8 connects the left side clamp body 1 and the right side clamp body 2 through threaded holes, and is fastened by the first hexagon nut 5, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com