Machine room air conditioner control system

A control system, a technology for computer room air conditioners, applied in heating and ventilation control systems, control inputs involving air characteristics, space heating and ventilation control inputs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

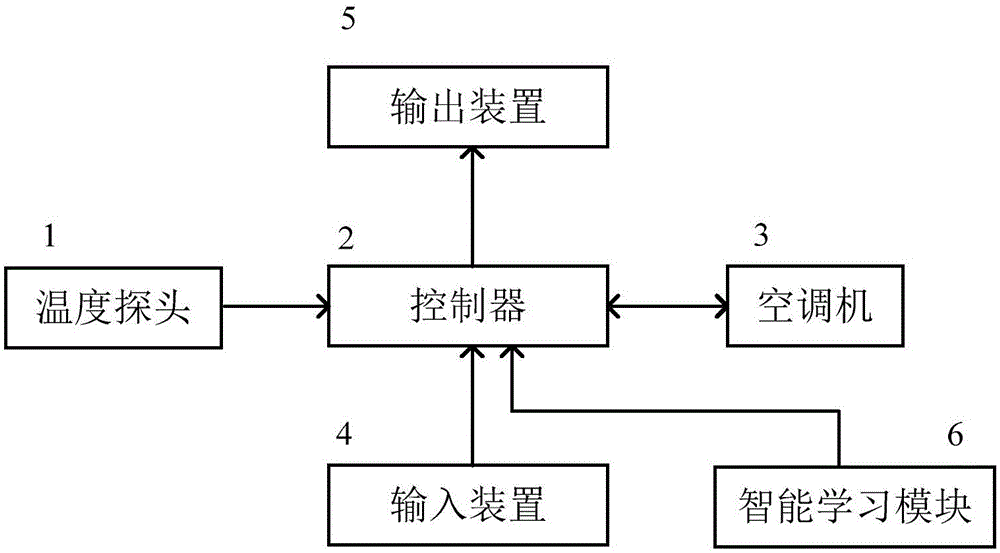

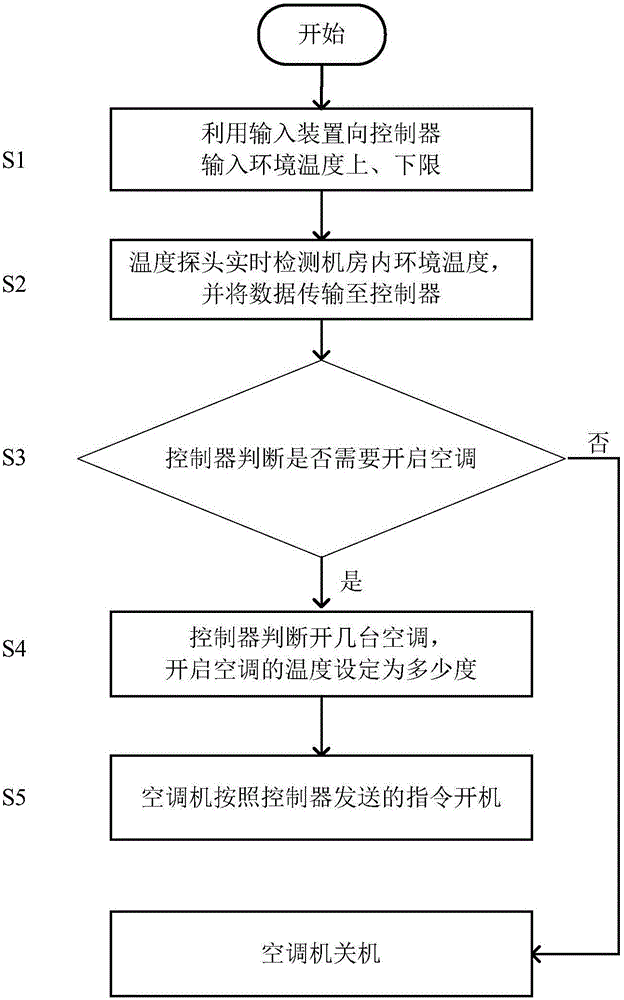

[0020] Such as figure 1 As shown, a computer room air-conditioning control system includes an input device 4, an output device 5, a temperature probe 1, a controller 2 and an air conditioner 3; the input device 4 is connected to the controller 2, and is used to input preset The upper and lower limits of the ambient temperature; the temperature probe 1 is connected to the controller 2 for real-time detection of the ambient temperature in the computer room, and the detected data is transmitted to the controller 2 in real time; the output device 5 is connected to the controller 2 for display The temperature in the computer room; after the controller 2 receives the ambient temperature in the computer room transmitted by the temperature probe 1, it judges whether to turn on the air conditioner 3; when the ambient temperature in the computer room is higher than the upper limit of the preset ambient temperature or lower than the lower limit of the preset ambient temperature , the con...

Embodiment 2

[0024] The difference from the computer room air-conditioning control system in Embodiment 1 is that the controller 2 also includes an intelligent learning module 6, which can copy the control codes in the original remote control of the air conditioner to adjust the temperature of the air conditioner 3 during operation. Adjust the operation of the air conditioner according to specific needs.

[0025] When in use, the intelligent learning module 6 first copies the control code in the remote controller of the original air conditioner; the input device 4 inputs the upper and lower limits of the preset ambient temperature to the controller 2; the temperature probe 1 transmits the ambient temperature data to the controller 2 in real time, After the controller 2 receives the ambient temperature in the computer room transmitted by the temperature probe 1, it judges whether it is necessary to turn on the air conditioner 3; when the ambient temperature in the computer room is higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com