Paddy fields in the south mainly grow rice and rapeseed crops, and the paddy fields are almost full of water all the year round, there is no freezing in winter, the land is wet, and the soil bearing capacity is poor. Cause the teeth to damage the structure of the plow bottom layer, resulting in soft plow bottom layer

And with the repeated operation of the wheeled operation machinery, the depth of the plow bottom layer continues to deepen. Every time plowing will cause the plow bottom mud layer to deepen once. When the plow bottom layer deepens, larger diameter wheels and larger horsepower and weight Driven by operating machinery, it will cause a vicious circle, making the paddy field a deep muddy field. Finally, when it reaches a certain level, it will easily lead to the inability of tillage machines, rice transplanters, combine harvesters and other machinery to work in the field

Although flooded rice fields can increase crop yields, reduce heavy metal pollution, reduce the amount of chemical fertilizers, and protect farmland water and soil, continuous flooding near the rice harvest season will make the rice fields softer, and traditional wheeled agricultural machinery is prone to slipping or getting stuck when entering the rice fields , thus failing to complete basic tasks

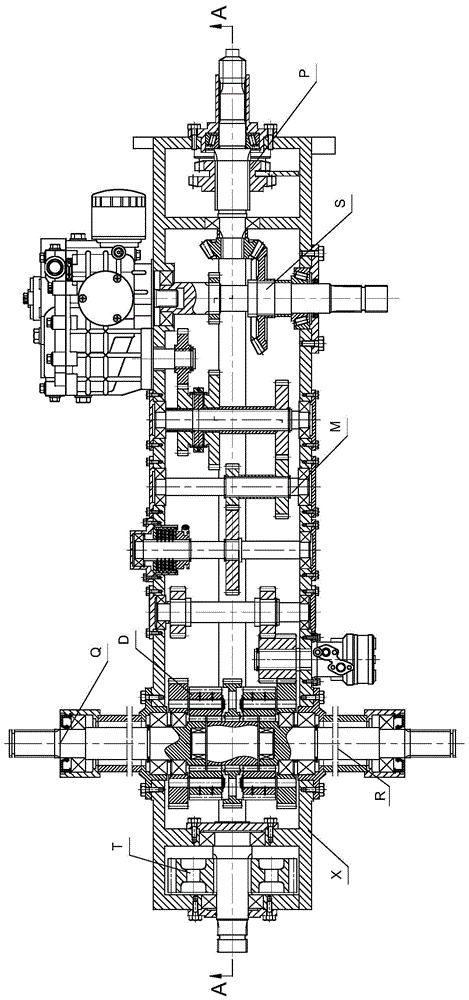

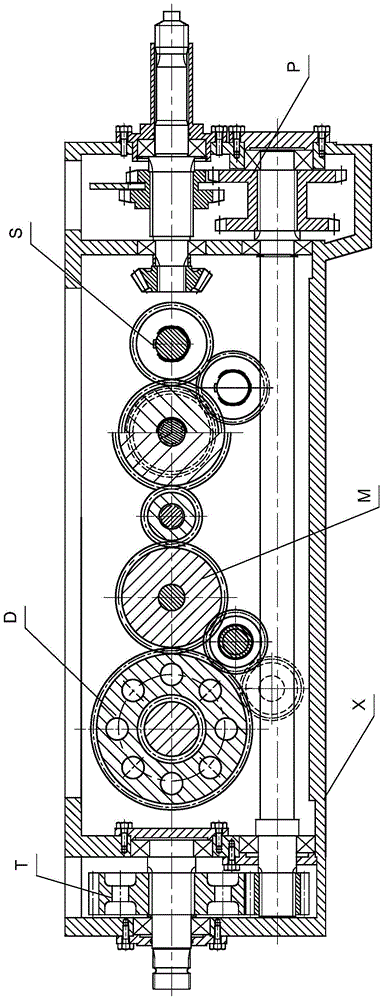

[0003] Because the grounding area of tracked vehicles is large, and the grounding specific pressure of the crawler is small, its value is close to the grounding specific pressure of human beings, so it is especially suitable for the southern paddy fields. At present, the crawler-type operating vehicles in the southern paddy fields mainly include crawler tractors and crawler harvesters. However, the variable speed transmission systems of these tracked vehicles usually adopt two types, one is the pure mechanical power transmission system to transmit power, which has the advantages of simple structure and high efficiency, but the pure mechanical power transmission mechanism has complex gear shifting operations, and at the same time Because agricultural machinery operators usually do not have the skills to drive cars or tractors, it is difficult to control the coordination of clutch, accelerator and gear shifting, which limits the development of tractors; The drive system, because the driving operability of the crawler tractor with the stepless drive system has been improved, the agricultural machinery operator does not need to participate in professional technical training, and only needs simple training to master the driving skills, so it is accepted by the majority of users and has achieved very good results. effect, but adding the hydraulic system increases the complexity and manufacturing cost of the operating system

In daily production and use, crawler tractors are usually attached to agricultural machinery. When agricultural machinery is working in the field, the engine is generally in a state of high throttle, which is close to the rated operating condition of the engine. The speed changes little, and the power and torque of the machine are relatively large. , so easily lead to problems such as high energy consumption, high heat generation, and poor high-temperature stability in the hydraulic system, and even the conventional plowing operation cannot be realized, which seriously limits the application range of crawler tractors and increases energy consumption.

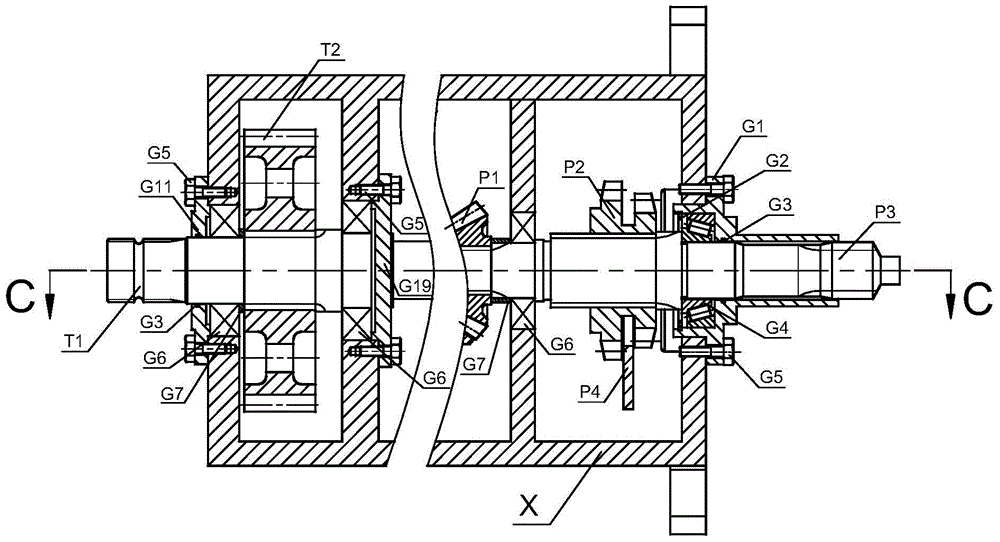

[0004] At the same time, because the working principle of the tracked vehicle driving system is similar to that of the two-wheeled agricultural machinery, the transmission usually integrates one or more functions such as steering, differential speed, main deceleration, and braking; but at least the steering function is integrated, Its steering function usually uses the steering rod to operate the jaw clutch and multi-disc brake. The specific realization process is: when the crawler tractor turns to the left, the driver operates the left steering rod to separate the left jaw clutch. Braking with the left output shaft, because the transmission power on the left side of the crawler tractor vehicle is interrupted and braked to stop the rotation, at this time, driven by the power on the right side of the tractor, the implement turns to the left; similarly, it can turn to the right, but This kind of steering mechanism is realized by separating and combining jaw clutches and brakes, which has low steering precision and poor steering controllability

Login to View More

Login to View More  Login to View More

Login to View More