A detachable base form steel truss floor deck and its assembly method

A steel truss and assembly method technology, which is applied in the field of steel structures, can solve the problems of high production and processing costs, complex connectors, and high dismantling costs, and achieve the effects of stable connection strength, excellent economic performance, and convenient formwork removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

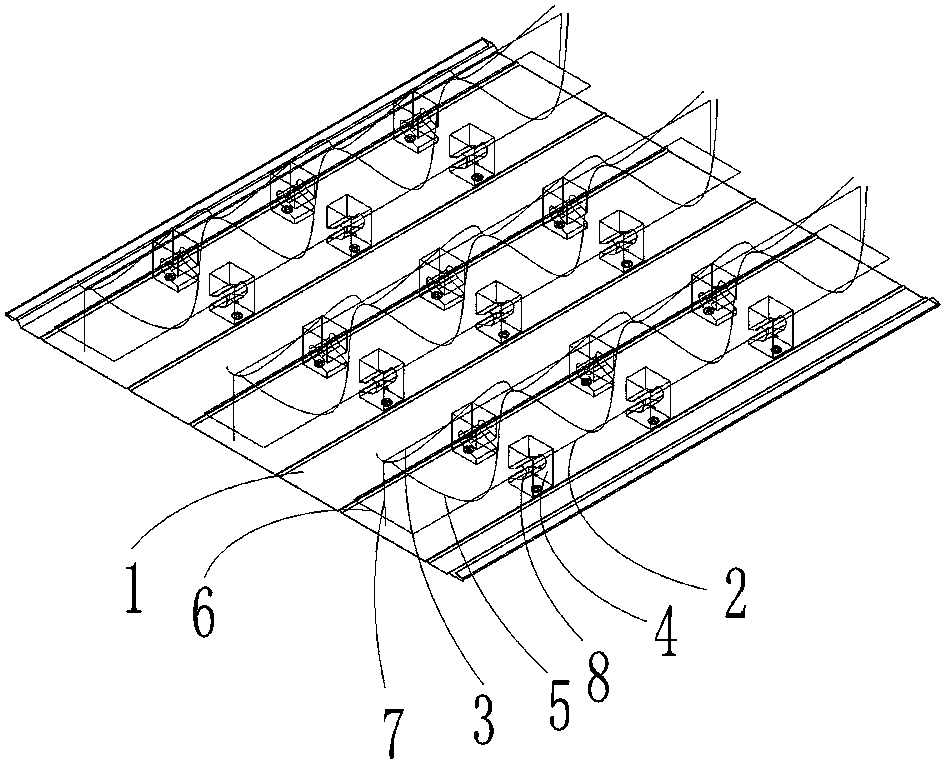

[0019] Example 1: as figure 1 As shown, a detachable bottom form steel truss floor deck includes a bottom formwork 1, and more than one set of steel bar truss assemblies are arranged in the bottom formwork 1, and the steel bar truss assemblies include lower chord steel bars 2 and upper chord Reinforcing bar 3, described lower chord reinforcing bar 2 is positioned by the positioning block 4 that is fixed on the bottom formwork 1, and the middle position above described lower chord reinforcing bar 2 is provided with upper chord reinforcing bar 3, and described upper chord reinforcing bar 3 and lower chord reinforcing bar 2 Be provided with web bar steel bar 5.

[0020] There are two lower chord reinforcing bars 2, and the two lower chord reinforcing bars 2 are distributed in a horizontal straight line, and the outer ends between the two lower chord reinforcing bars 2 are fixed by a cross bar 6, and the cross bar 6 and the upper chord reinforcing bar 3 are arranged There is a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com