Four-cylinder closed hydraulic bucket for rotary excavating pile machine

A technology of hydraulic grab bucket and rotary pile driver, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems that the grab bucket cannot be cut in depth, the grab bucket cannot be closed in place, and the verticality is difficult to precisely control, etc. Equipment purchase cost, not easy to tilt, and good operation orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

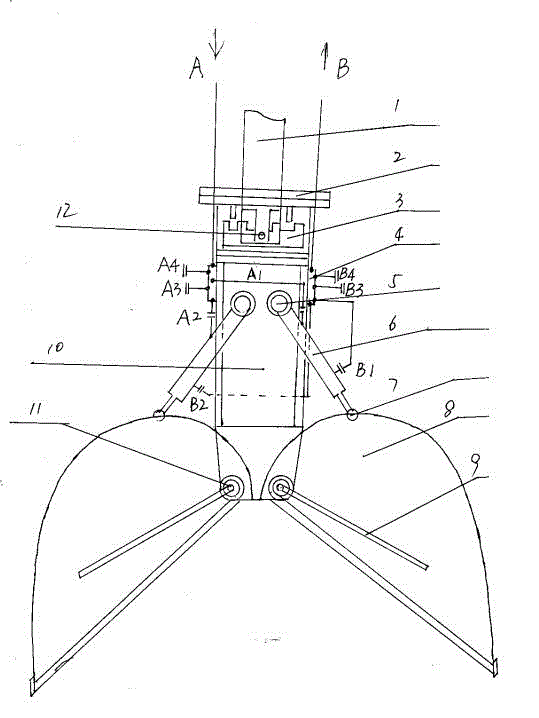

[0010] Such as figure 1 As shown, the four-cylinder closed hydraulic grab of the present invention mainly includes a hydraulic cylinder 6, a toothed disc articulator 3, a grab bucket 8, a bulldozer plate 9, a column 10, a grab winch 11, a cylinder twist shaft 5, and a cylinder connecting shaft 7. Oil circuit distribution block 4, flange 2; telescopic drill pipe 1 passes through the flange 2 at the upper end of the tooth disc articulator 3, inserts it into the sleeve groove at the lower half of the tooth disc articulator 3, and inserts it into the tooth disc through the pin 12 Inside the articulator 3; the lower end of the gear plate articulator 3 is connected with the column 10, the column 10 is a hollow square tube, the top of the column 10 is provided with four oil cylinder twisted shafts 5, and the four oil cylinder twisted shafts 5 are arranged along the same length of the column 10. An outer periphery is arranged on the column 10; the lower end of the column 10 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com