a carrier

A technology for carrying devices and pallets, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of insufficient sorting, inability to slide off the pallet, and reduced efficiency of goods sorting, to reduce friction, reduce Contact area, the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

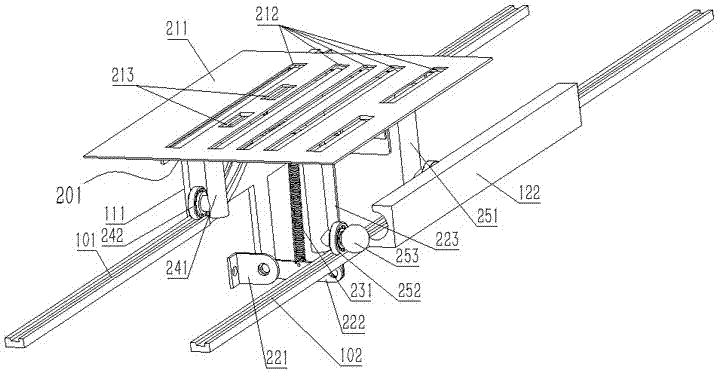

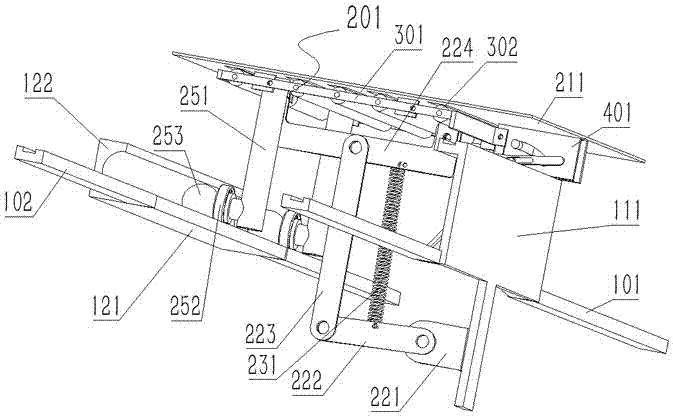

[0021] The embodiment of logistics sorting device among the present invention: as Figure 1 to Figure 8 As shown, the logistics sorting device is a sorting device of the logistics sorting system corresponding to the sorting chutes preset at different positions in the conveyor line of the logistics system. There are multiple devices 201, and they are arranged on the track device at intervals along the forward and backward conveying direction, so that the carrier device 201 with goods moves forward under the drive of the track device. When the goods arrive at the predetermined sorting chute, the track device The carrying device 201 will be tilted, so that the goods on the carrying device 201 are poured into the sorting chute, and the sorting of the goods is completed.

[0022] The track device is mainly composed of a left track, a right track and a traction mechanism. The left track and the right track are parallel to each other, and the right track is the near side track 102 cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com