3D fabric production equipment, production process and 3D fabric

A technology of production technology and production equipment, applied in the field of production technology and 3D fabrics, can solve the problems of high cost and complicated patterns, and achieve the effects of rich patterns, obvious 3D effect and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] Such as Figure 4 As shown, a 3D fabric production equipment includes two printing rollers 8 engaged up and down, and at least one of the printing rollers 8 has a plurality of grooves 81 on its surface.

[0028] In this embodiment, a plurality of grooves 81 are formed on the surface of the lower printing roller 8 . The plurality of grooves 81 can be grooves of regular shape or irregular shape, depending on the actual shape of the printing.

[0029] Such as Figure 5 Shown, a kind of 3D fabric production process comprises the following steps:

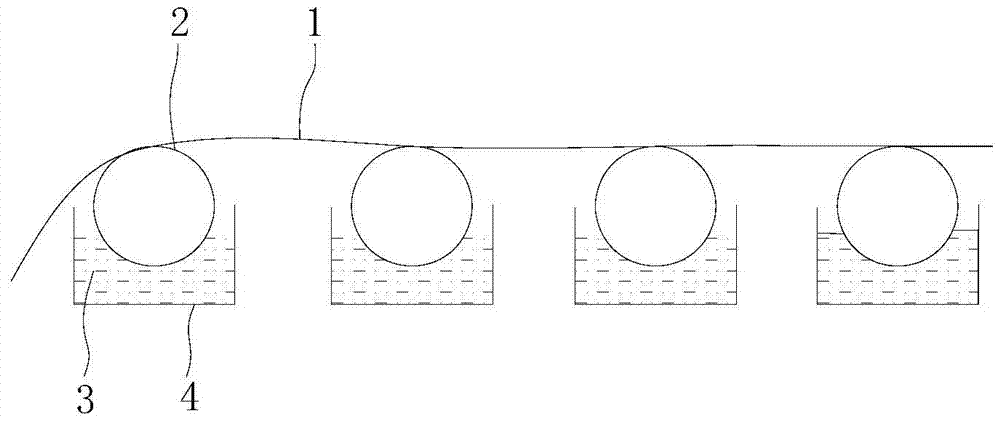

[0030] Step 1: stick the heat transfer paper 1 with the pigment 3 to obtain the heat transfer paper with the paint attached;

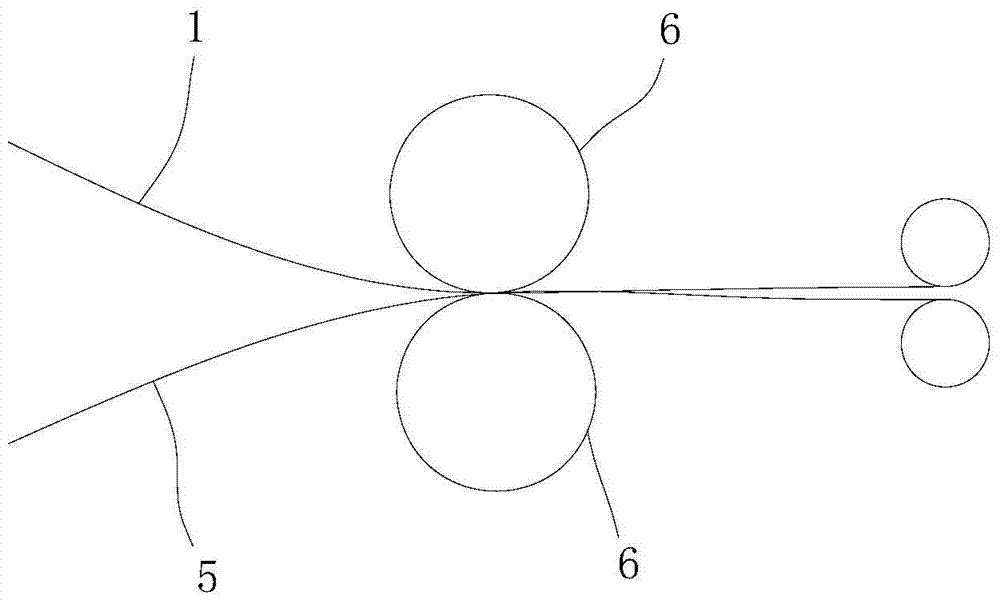

[0031] Step 2: Preheating the thermal transfer paper with pigments and gray cloth 5 obtained in Step 1;

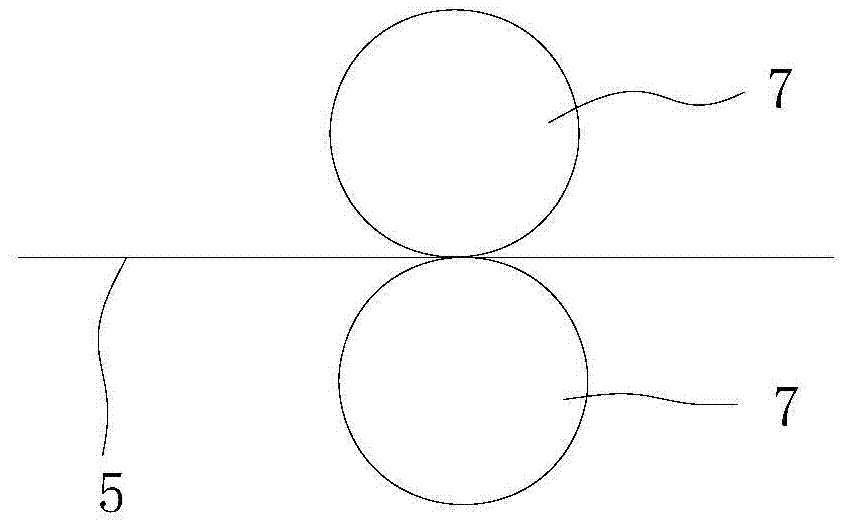

[0032] Step 3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com