Low-pressure casting mold for motor water-cooled housing

A low-pressure casting and water-cooling technology, applied in the field of low-pressure casting molds, can solve the problems of complex production process, high production cost, and poor heat dissipation effect, and achieve the effect of good mechanical performance, low production cost, and accurate fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

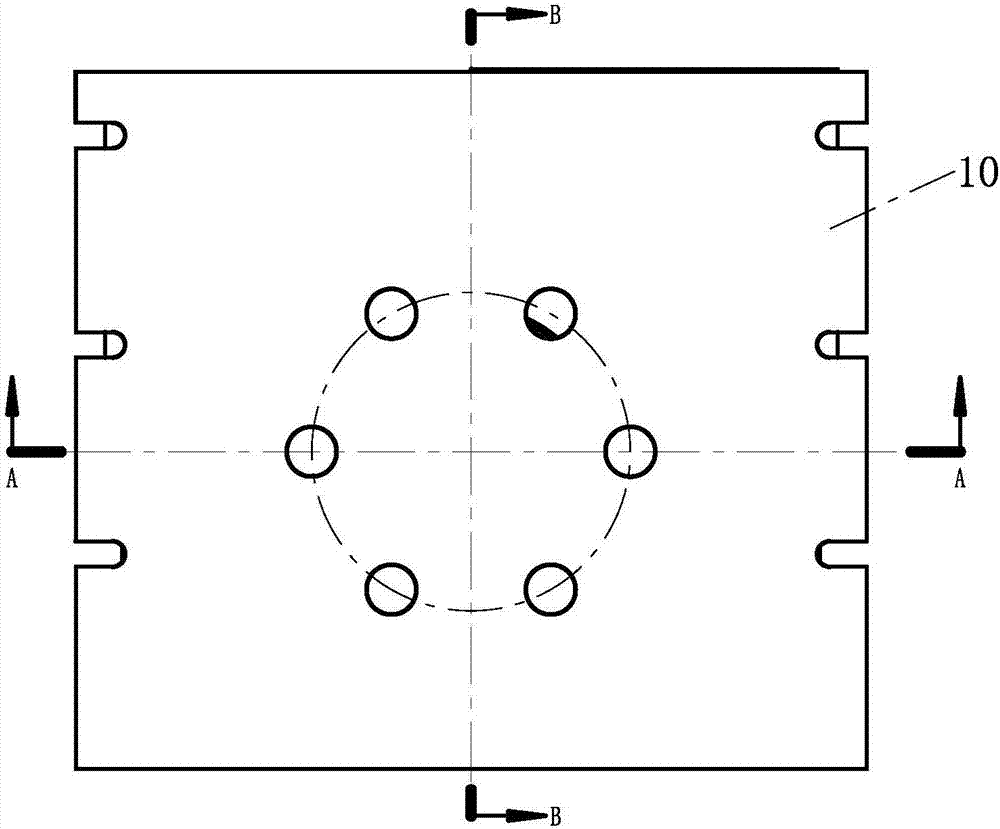

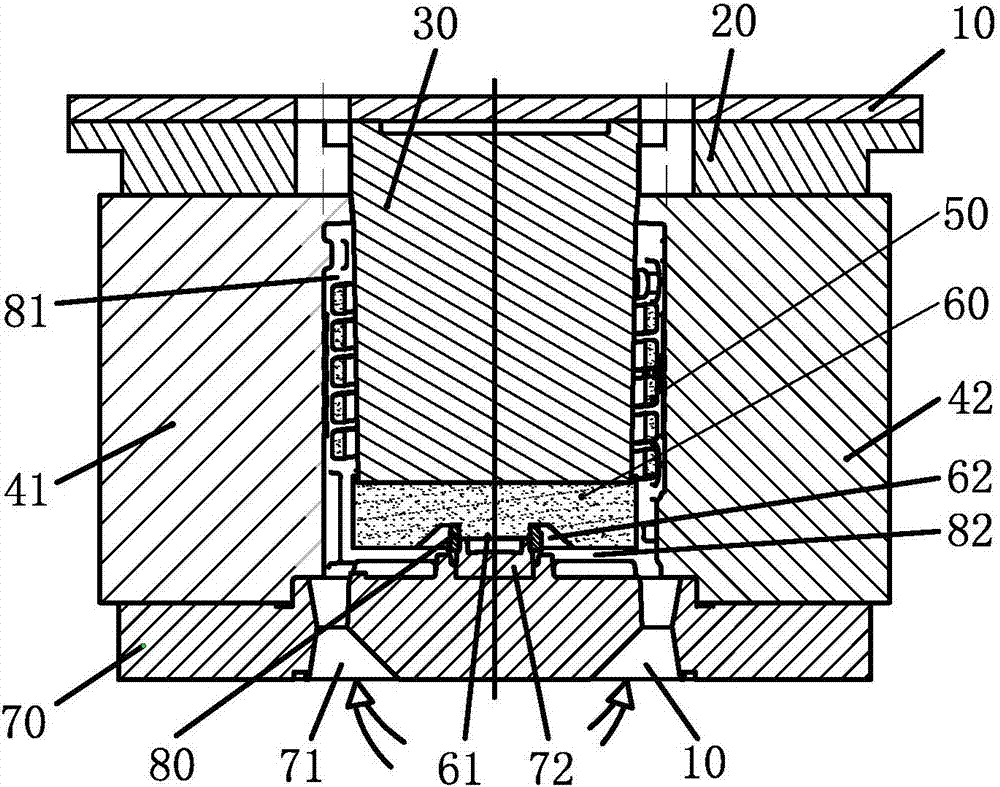

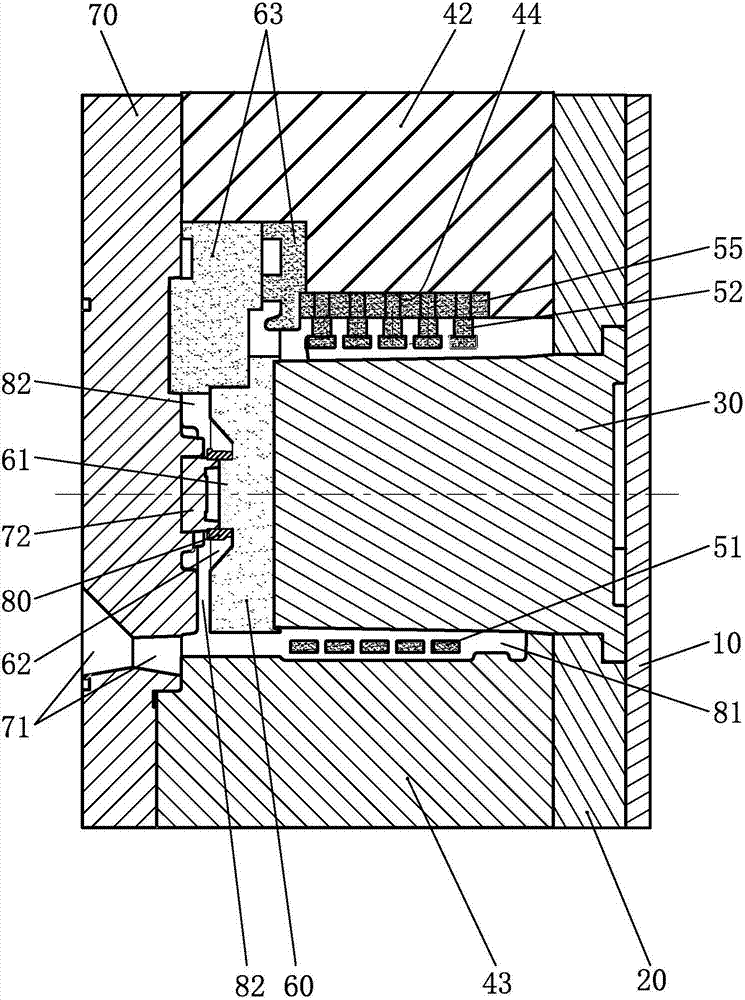

[0023] The present invention will be further described below with specific embodiments in conjunction with the drawings, see figure 1 — Figure 5 :

[0024] The low-pressure casting mold of the motor water-cooled shell is located at the bottom of the annular cylinder surrounded by three or more movable modules 41, 42, 43 with arc-shaped inner surfaces, and the upper part of the middle cavity formed by the base plate 70 is positioned. The central pillar fixing plate 20 is fixed with the mold central pillar 30, the side of the casting mold central pillar 30 and the inner surface of the annular cylinder and the lower surface of the central pillar fixing plate 20 form an annular cavity 81, the central pillar 30 and the base plate Between the upper surface of 70 and the inner surface of the annular cylinder, a lower mold cavity communicating with the annular mold cavity 81 is formed. The annular mold cavity 81 is suspended with a spiral water channel mud core 50, and the water inlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com