Straightening-ring locking device combining taper sleeve expansion and key transmission

A technology of straightening ring and key transmission, which is applied in the field of cantilever type steel straightening machines, can solve the problems of inability to meet the locking of wide-sized straightening rings and the need for quick replacement of straightening rings, and achieves convenient installation and replacement. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

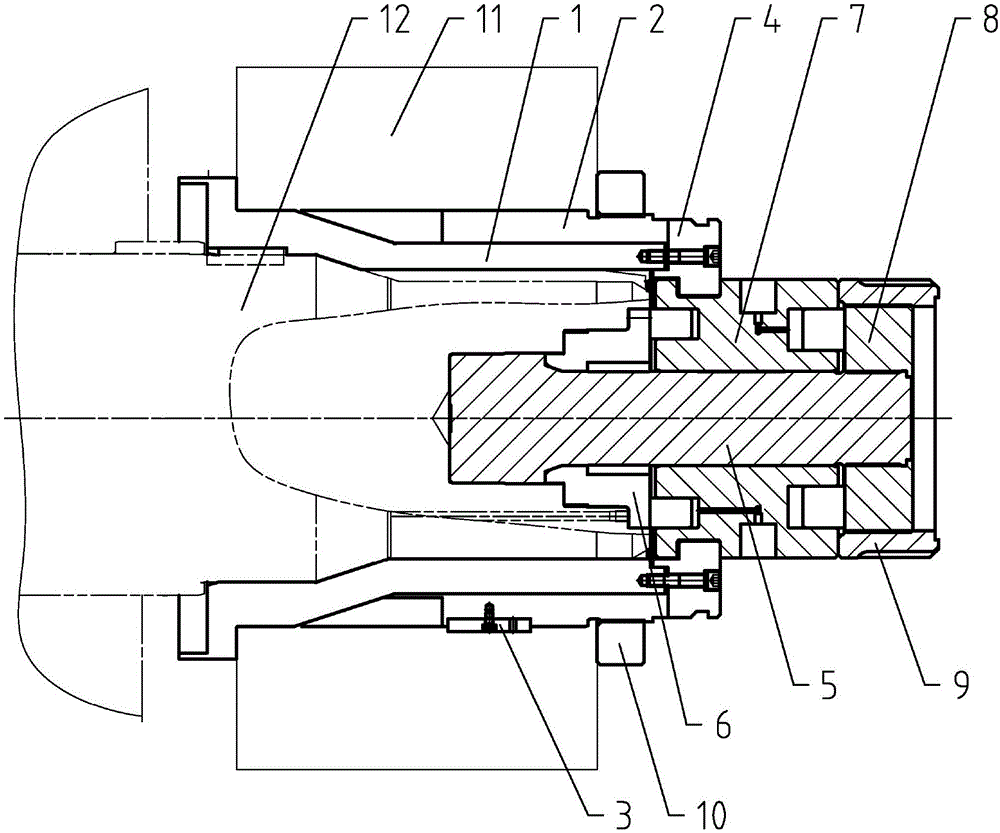

[0017] The present invention will be further described below in conjunction with drawings and embodiments. As shown in the accompanying drawing, the embodiment of the straightening ring locking device combined with the expansion of the taper sleeve and the key transmission,

[0018] Straightening ring locking device combining tapered sleeve expansion and key transmission, including: straightening roller 12, straightening ring 11, inner tapered sleeve 1, outer tapered sleeve 2, transmission key 3, spline sleeve 4, tie rod 5 , fixed nut 6, hydraulic nut 7, pressure nut 8, lock nut 9 and safety nut 10, the cantilever shaft of the straightening roller 12 is a second-order shaft, the first-order shaft is a large-diameter straight shaft section, and the second-order shaft is a small Diameter straight shaft section, between the first-stage shaft and the second-stage shaft is a tapered shaft section, the inner tapered sleeve 1 is composed of three sections, one end is a large diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com