A centering mechanism for horizontal ultra-high pressure sterilization equipment

An ultra-high pressure sterilization and equipment matching technology, which is applied in food science, food preservation, application and other directions, can solve the problems of the plugs entering and exiting the ultra-high pressure cylinder not smoothly, easily damaging the plug sealing ring, and the axes are not easy to coincide, etc. Achieve the effect of eliminating the coaxial adjustment link, improving the support rigidity, and improving the relative movement accuracy of the coaxial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention provides a centering mechanism for horizontal ultra-high pressure sterilization equipment. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

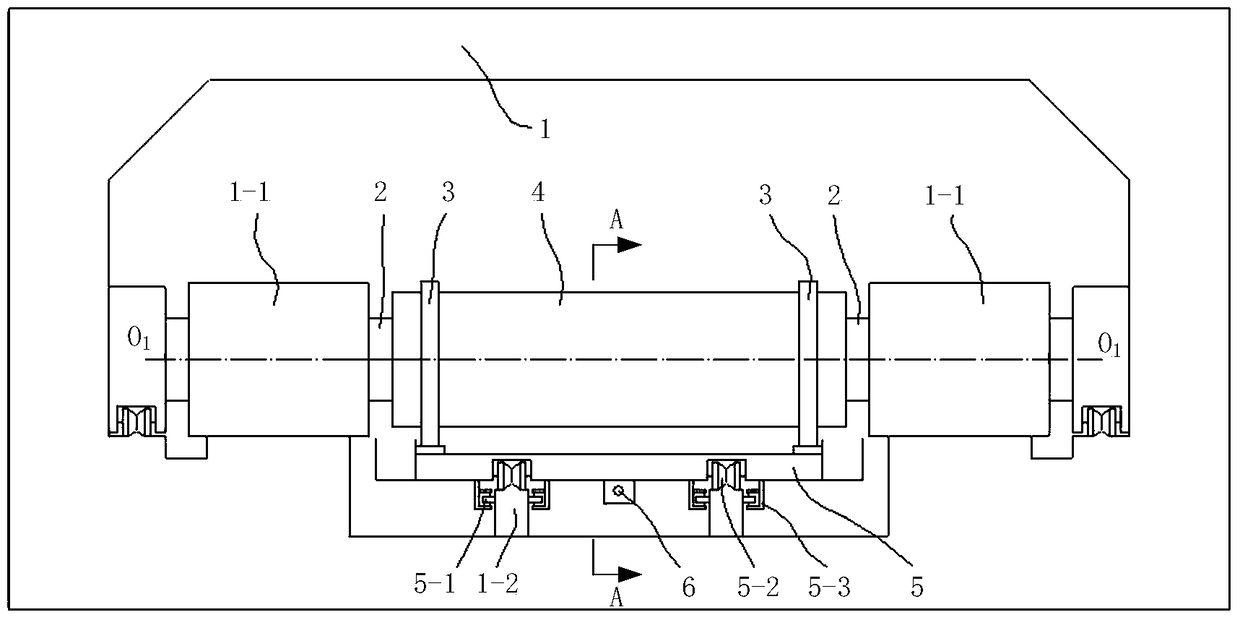

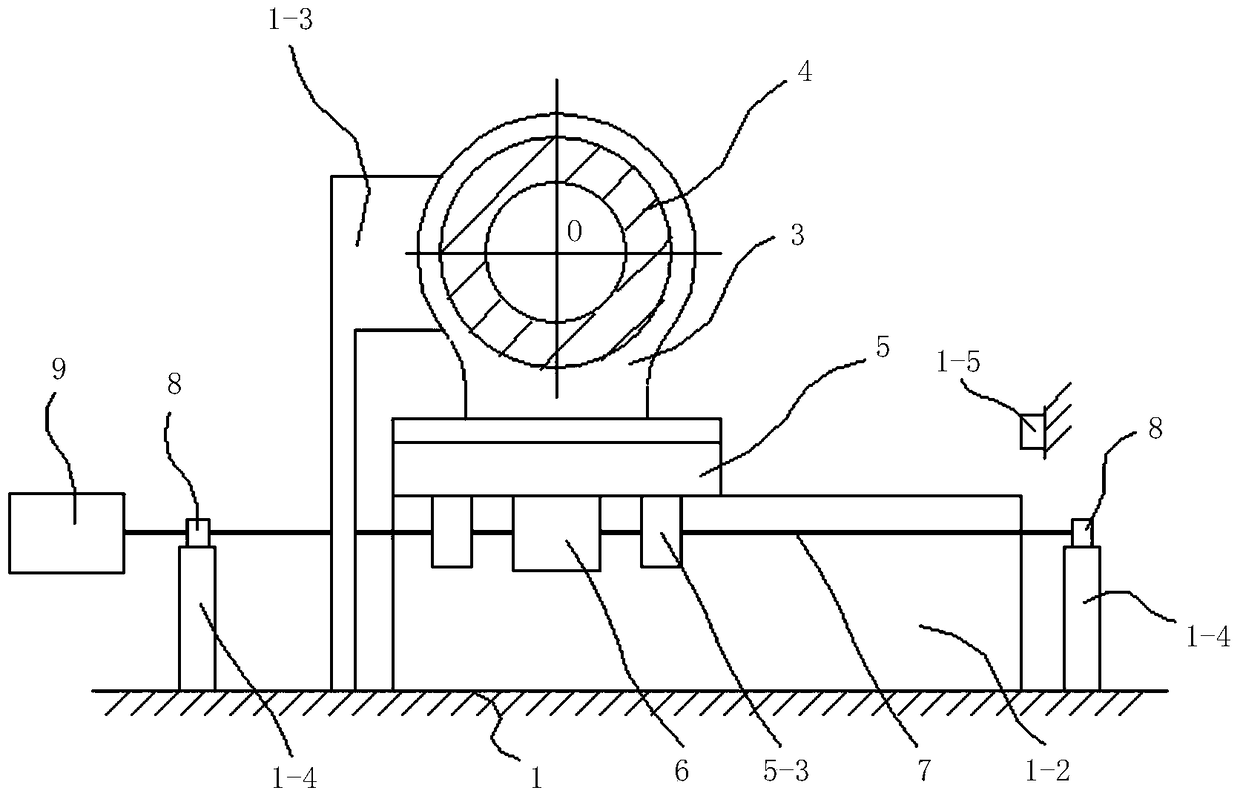

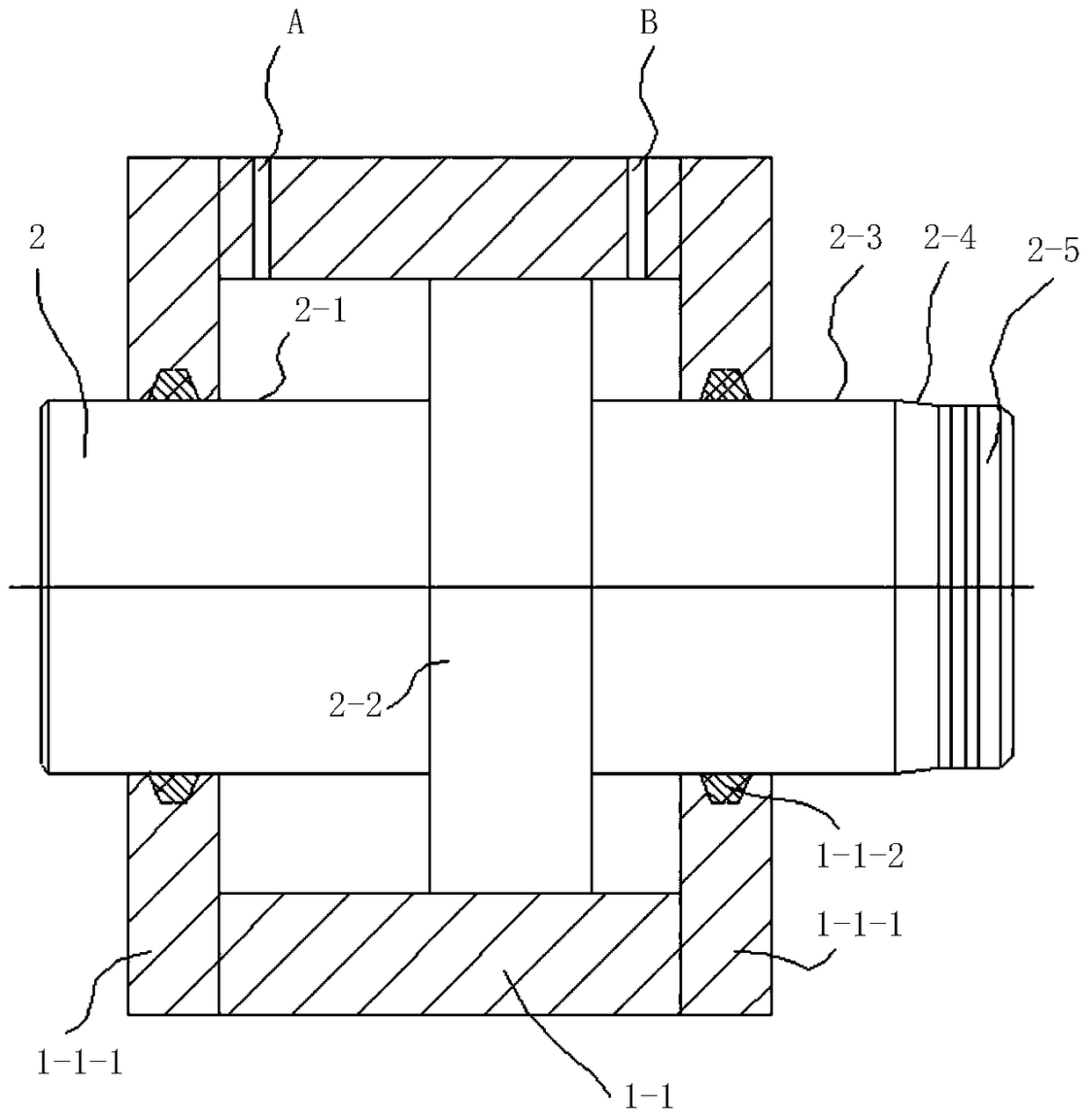

[0027] Such as figure 1 and figure 2 As shown, a centering mechanism of a horizontal ultra-high pressure sterilization equipment provided by the present invention includes a frame 1, a cylinder body 1-1, a trolley rail beam 1-2, a centering positioning block 1-3, and a bearing support column 1- 4. Positioning block 1-5 for trolley feeding position, piston plug 2, cylinder body fixing seat 3 and trolley frame 5: left and right cylinder body 1-1, left and right trolley guide rail beam 1-2, left and right alignment positioning Blocks 1-3, front and rear bearing support columns 1-4, trolley feeding position positioning blocks 1-5 and frame 1 are integrated; The guide rail beam 1-2 is vertically symmetrically arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com