Method for determining the state of a fire-resistant lining of a metallurgical vessel for molten metal in particular

A technology for melting metal and refractory lining, which is applied in the direction of lining repair, furnace monitoring device, furnace, etc., and can solve problems such as the impossibility of comprehensive confirmation of furnace lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

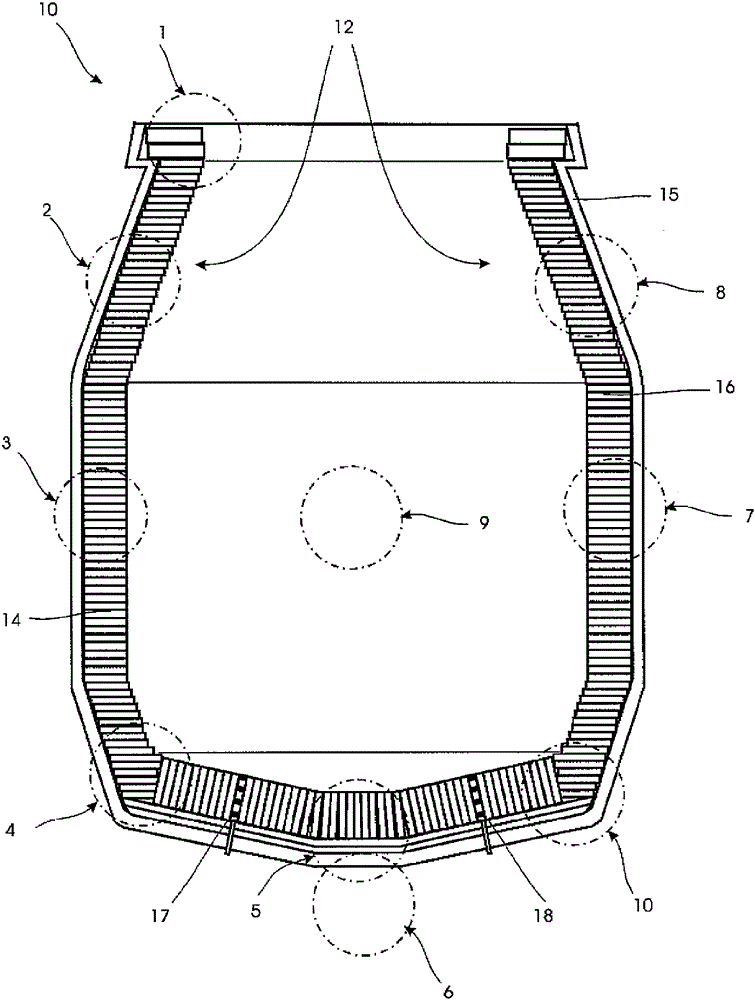

[0012] The present method particularly relates to metallurgical furnaces, one such furnace 10 is shown in figure 1 As an example in the cross-section. In this example, the furnace 10 is a converter, known per se, for the manufacture of steel. The furnace 10 basically consists of a metal casing 15, a refractory lining 12 and gas purge plugs 17, 18 which can be coupled to a gas source (not shown in detail).

[0013] The molten metal poured into this furnace 10 during operation is metallurgically processed, for example by a blowing process, which process will not be described in any further detail. Typically a large number of these converters 10 are used simultaneously in a steel plant and data is recorded for each of these converters.

[0014] It goes without saying that the method can be used in different metallurgical furnaces, such as for example in electric furnaces, blast furnaces, ladles, furnaces in the field of non-ferrous metals, such as aluminum melting furnaces, cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com