Hazardous material solid oxidation property detection apparatus

A detection device and oxidative technology, which is applied in the direction of chemical analysis by combustion, can solve the problems of insufficient scientific accuracy of data, potential safety hazards, and technical requirements for the measurement of ignition temperature, sample heating power and time of the ignition device, etc., and achieve the safety of experimental operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The preparation of embodiment 1 reference material Potassium bromate and dry cellulose silk

[0101] Select 3000 g of dry cellulose filaments with a length in the range of 50 μm to 250 μm and an average diameter of 25 μm, dry the selected dry cellulose filaments at a temperature of 105° C. for 6 hours to a constant weight, cool them for use, and test , the water content in the dry cellulose silk is 0.3%.

[0102] Commercially pure potassium bromate is sieved but not ground, and 1000 g of potassium bromate with a particle size of 0.15 mm to 0.3 mm is selected, dried at 65° C. for 12 hours to a constant weight, and cooled for later use.

Embodiment 2

[0103] Embodiment 2 Inspection of sample to be tested

[0104] Check whether the sodium nitrate to be tested contains particles with a diameter of less than 500 μm. If the particles with a diameter of less than 500 μm account for more than 10% of the total weight, or the substance is fragile, all the particles to be tested should be removed before the test. The sample is ground into powder.

Embodiment 3

[0105] The mixing of embodiment 3 potassium bromate and dry cellulose silk

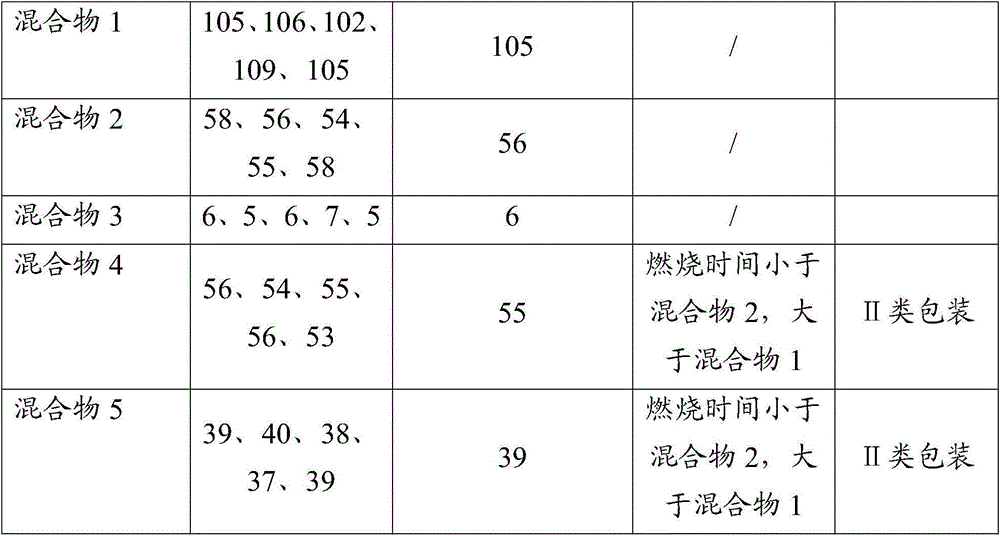

[0106] Weigh 30g of potassium bromate and 210g of dry cellulose silk according to the mass ratio of 3:7 and mix them in a mechanical mixer to obtain fully mixed mixture 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com