A kind of chain grate boiler feeding device and method thereof

The technology of feeding device and chain grate is applied in the field of boiler feeding device, which can solve the problems of large ventilation resistance of fuel layer, reduce combustion efficiency, unscientific and so on, and achieve the effect of uniform size, avoiding burning hopper and efficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

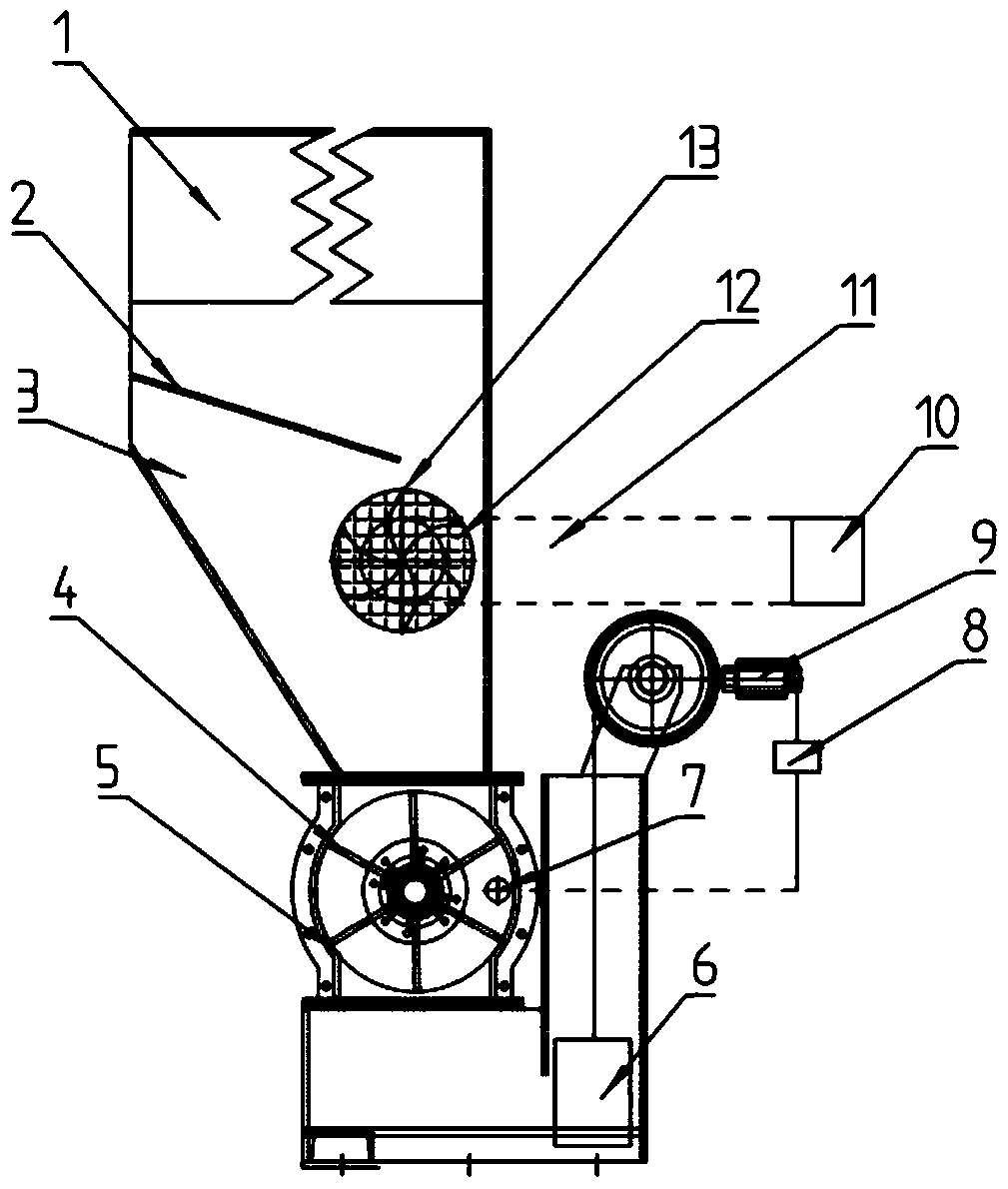

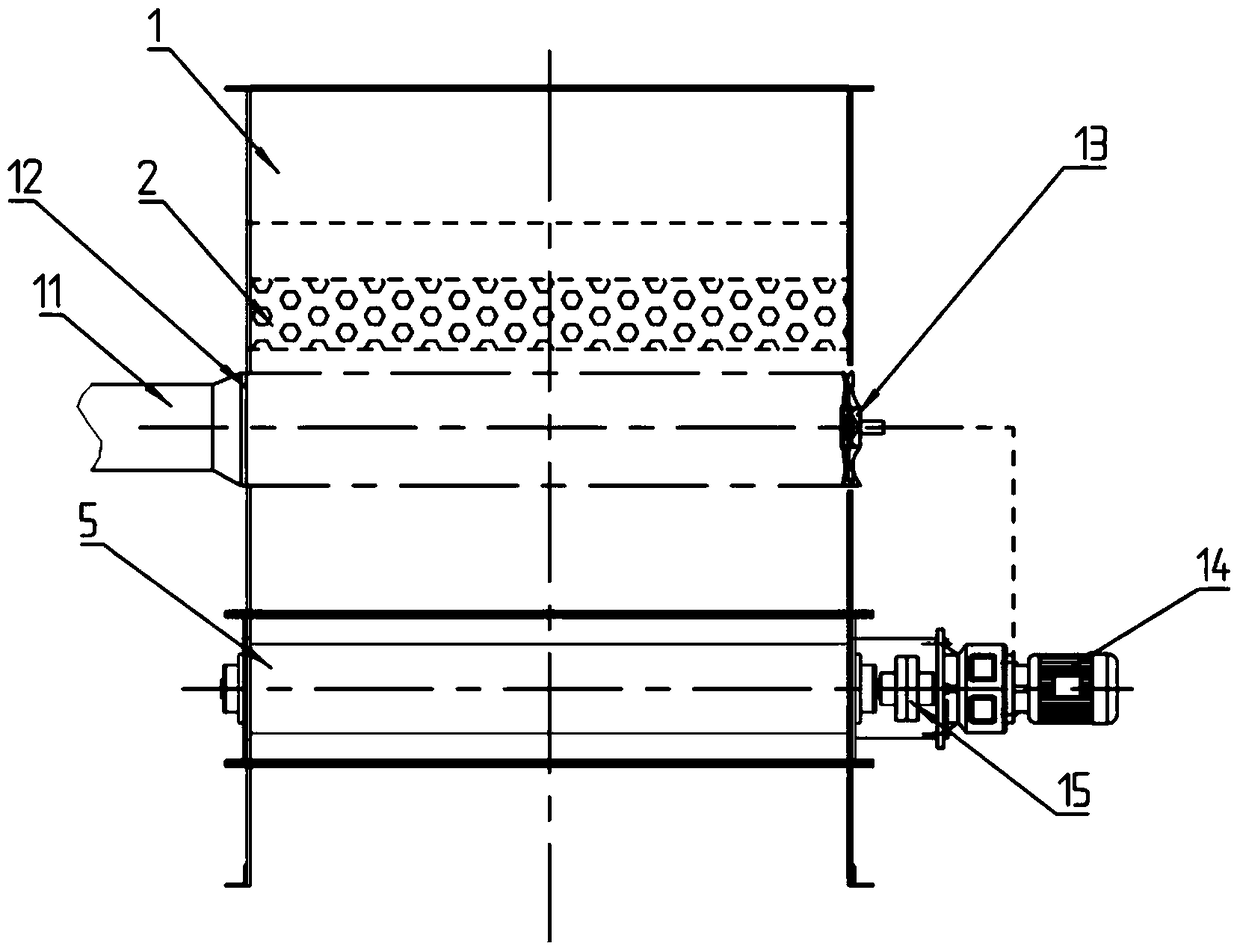

[0012] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is further described: as figure 1 , as shown in 2, a chain grate boiler feeding device includes a crusher 1, a slideway 2, a hopper 3, a silo partition 4, a silo retaining ring 5, a coal gate 6, a counter 7, a controller 8, a slide Differential motor 9, first combustion chamber 10, dust fuel channel 11, screen 12 and fan 13; Crusher 1 is placed above slideway 2, slideway 2 and hopper 3 are connected by bolts, fan 13 is installed on hopper 3, The hopper 3 is connected to the silo, the silo is composed of the silo partition 4 and the silo retaining ring 5, the counter 7 is installed on the silo retaining ring 5, and is connected to the controller 8 through wires, and the controller 8 is connected to the slip motor 9 are connected, the slip motor drives the coal gate 6 to complete the lifting, the dust fuel channel 11 is connected between the first combustion chamber 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com