Micro combustor with built-in cross partition plate

A micro-combustion and cross-baffle technology, applied in the direction of burners, gas fuel burners, combustion types, etc., can solve the problems of complex burner structure and insufficient convective heat transfer, and achieve uniform temperature distribution on the wall surface and the degree of turbulence Enhanced, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

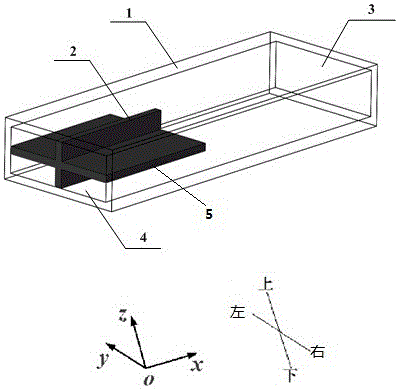

[0029] Such as figure 1 The built-in cross-baffle micro-burner shown includes 1. the outer wall of the burner, 2. a cross heat-conducting partition, 3. an air inlet, 4. an air outlet, and 5. a rectangular groove.

[0030] The built-in cross partition type miniature burner of the present invention includes a burner outer wall 1, a cross heat conducting partition 2, an air inlet 3 and an air outlet 4, and the burner outer wall 1 is divided into upper and lower walls and left and right walls ;

[0031] Both ends of the burner are respectively provided with an air inlet 3 and an air outlet 4;

[0032] The inside of the burner is provided with a cross heat conduction partition 2, and the cross heat conduction partition 2 is perpendicular to the longitudinal partition;

[0033] The cross heat conduction partition 2 is arranged at one end of the air outlet 4, and the transverse partition and the longitudinal partition of the cross heat conduction partition 2 are detachably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com