Large-span steel corrugated plate arch bridge reinforcement structure

A technology for strengthening structures and corrugated plates, which is applied in the direction of bridge reinforcement, bridges, bridge materials, etc., can solve the problems of structural instability, thin thickness of steel corrugated plates, etc., achieve simple structure, low cost, and solve structural instability problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in combination with specific embodiments.

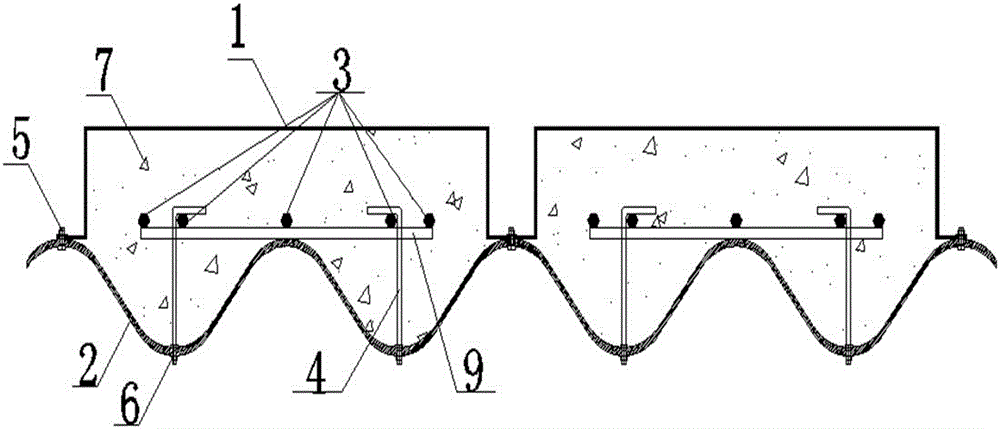

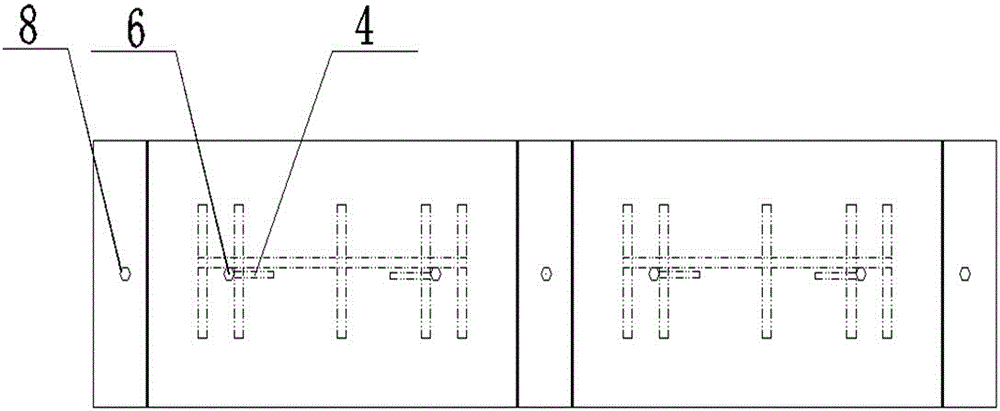

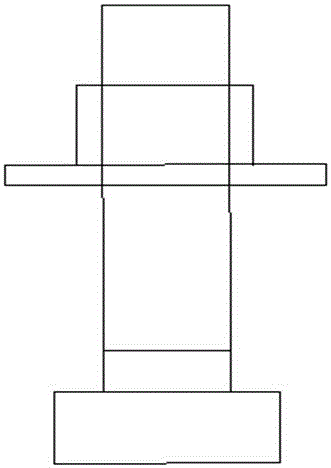

[0024] The invention relates to a large-span steel corrugated plate arch bridge reinforcement structure, comprising a steel corrugated plate 2 composed of spliced single plates, a plurality of channel-shaped steel plates 1 adjacently arranged longitudinally above the steel corrugated plate 2, and a horizontal channel-shaped steel plate 1 The cross-section is in the shape of a "several" with the notch facing down. Both ends of each channel-shaped steel plate 1 are provided with channel-shaped steel plate fixing holes 8, which are fixed to two crests of the steel corrugated plate 2 by channel-shaped steel plate fixing bolts 5, with a wave crest in the middle. The ends of two adjacent channel-shaped steel plates 1 share the channel-shaped steel plate fixing bolts 5 .

[0025] Steel bars are arranged between the steel corrugated plate 2 and the channel steel plate 1 and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com