Automatic secondary leveling steel plate shearing production line

A production line and leveling technology, which is applied in the direction of shearing devices, shearing equipment, metal processing equipment, etc., can solve the problems of low precision, low efficiency, and poor consistency of secondary leveling, and achieve avoidance of damage and maintenance and high efficiency , Intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

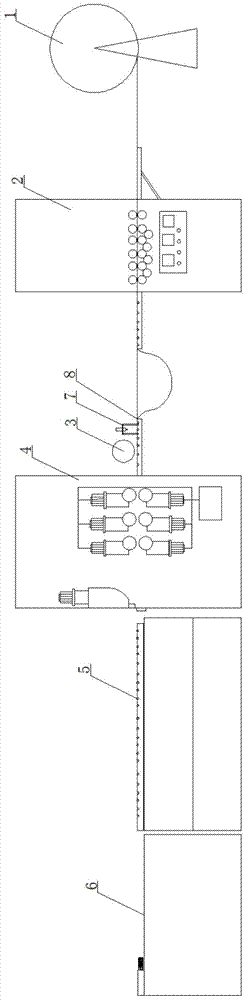

[0035] like figure 1 As shown, the automatic secondary leveling steel plate shearing production line includes uncoiler 1, primary leveling machine 2, distance measuring roller 3, conveyor belt 5, receiving machine 6 and transition conveyor belt 8, and secondary leveling and shearing Machine 4 and probe module 7, the unwinding machine 1, primary leveling machine 2, transition conveyor belt 8, secondary leveling machine 4, conveyor belt 5 and material receiving machine 6 are connected in sequence, and the probe module 7 and measuring The distance rollers 3 are sequentially arranged above the transition conveyor belt 8;

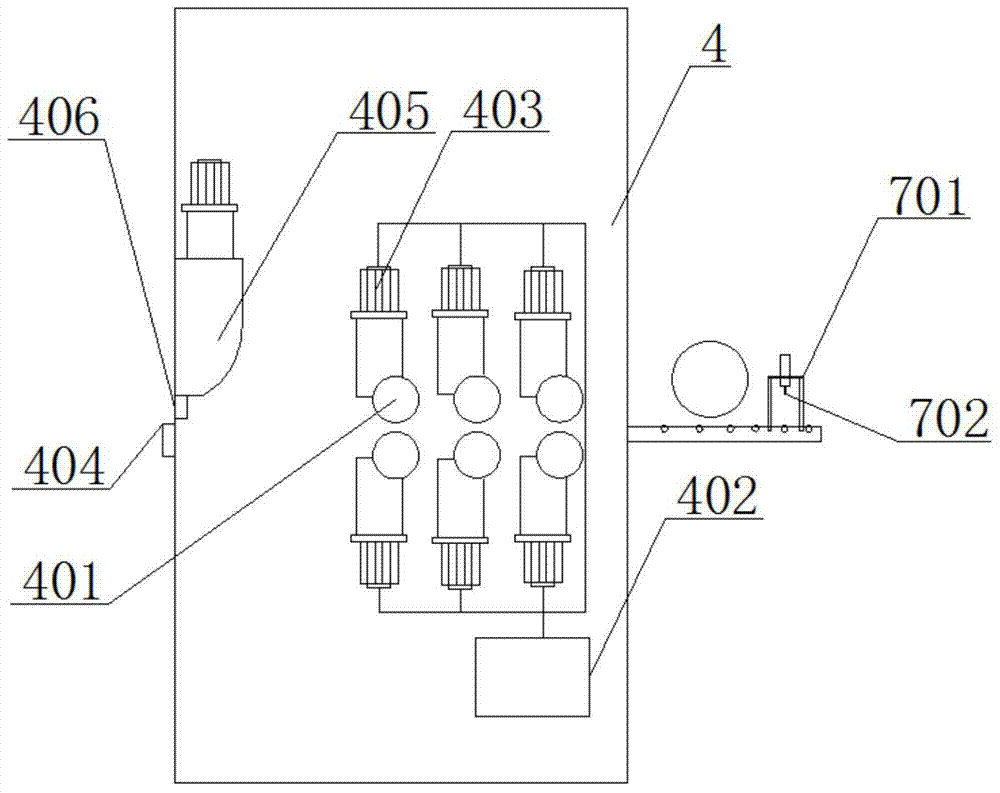

[0036] like figure 2 As shown, the secondary leveling and shearing machine 4 includes a leveling roller 401, a control box 402, a driving motor 403, a lower knife 404, a slider 405 and an upper knife 406, and the several leveling rollers 401 are opposite to each other. It is arranged symmetrically in the horizontal direction of the leveling entrance, and the ...

Embodiment 2

[0041] like figure 1 As shown, the automatic secondary leveling steel plate shearing production line includes uncoiler 1, primary leveling machine 2, distance measuring roller 3, conveyor belt 5, receiving machine 6 and transition conveyor belt 8, and secondary leveling and shearing Machine 4 and probe module 7, the unwinding machine 1, primary leveling machine 2, transition conveyor belt 8, secondary leveling machine 4, conveyor belt 5 and material receiving machine 6 are connected in sequence, and the probe module 7 and measuring The distance rollers 3 are sequentially arranged above the transition conveyor belt 8;

[0042] like figure 2 As shown, the secondary leveling and shearing machine 4 includes a leveling roller 401, a control box 402, a driving motor 403, a lower knife 404, a slider 405 and an upper knife 406, and the several leveling rollers 401 are opposite to each other. It is arranged symmetrically in the horizontal direction of the leveling entrance, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com